TPM

Effective Corrective and Preventive Actions (CAPA) for Enhanced Quality Management

Discover the importance of Corrective and Preventive Actions (CAPA) in maintaining and improving product quality, ensuring regulatory compliance, and enhancing customer satisfaction. This comprehensive guide explores the various elements of CAPA, helping organizations effectively implement this vital quality management process for long-term success.

Read More »A Comparative Analysis of Popular Continuous Improvement Methodologies: PDCA, DMAIC, A3, QRQC and 8D

Explore the differences between four popular continuous improvement methodologies - PDCA, DMAIC, A3, and 8D. This blog post offers a comprehensive comparison, examining their unique steps and applications, to help you choose the most suitable approach for your organization's improvement journey.

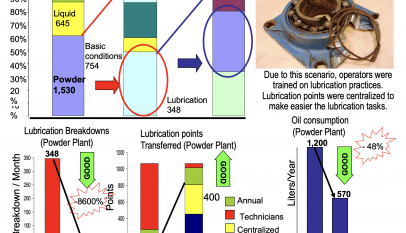

Read More »Planned Maintenance Case Study, Food Processing Plant

Discover how a food processing plant significantly improved its efficiency and reduced equipment breakdowns by implementing a planned maintenance approach. With a 40% reduction in breakdowns and a 20% increase in overall equipment effectiveness (OEE), this case study highlights the importance of a proactive and well-structured maintenance program for enhancing…

Read More »Preventive maintenance plan (PM program). Fundamental Phase Action Plan

There are seven very distinct elements or clusters to put in place in the Fundamental Phase. The elements are in a natural “make sense” order; some can be completed simultaneously with available resources. The last one, “Basic Maintenance Management,” can and should be inserted at the right time to aid…

Read More »