Quality

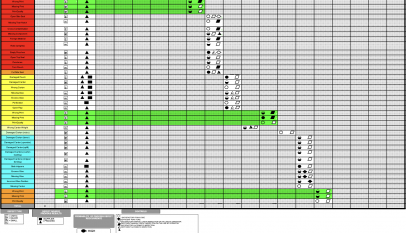

QA Matrix

Quality Assurance Matrix (QA Matrix) A QA matrix is a table that delineates how defects are being built into products under current conditions, in a process in which one wishes to assure quality. This matrix enables managers to see at a glance which processes are generating defects, which processes’ equipment…

Read More »Quality Function Deployment

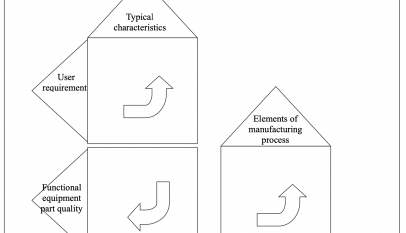

Converting the customer’s requirements into “quality characteristics” and developing a design quality for the finished product by systematically deploying the relationships between the requirements and the characteristics, starting with the quality of each functional component and extending the deployment to the quality of each part and process.System for obtaining the…

Read More »A Useful Quality Table

Many people have the idea that a quality table has to be some gigantic matrix combining a required quality deployment table and a quality characteristic deployment table. Quality tables, however, are not created for their own sake. They are tools to be used for an express purpose, and to that…

Read More »Quality Deployment and a Narrow Definition of Quality Function Deployment

Quality function deployment is a concept that originated in Japan, and although it is known worldwide by the acronym QFD, the name quality function deployment is a direct translation of the original Japanese name: hinshitsu kinô tenkai. It was originally proposed in 1978 by Drs. Yôji Akao and Shigeru Mizuno,…

Read More »