Understanding the Purpose of Nelson’s Rules

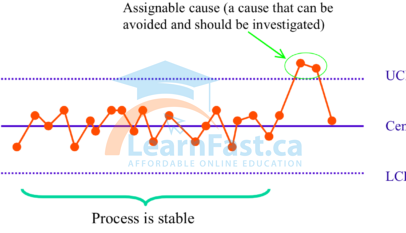

In process improvement and quality control, the earlier you detect a deviation, the faster you can fix it. Nelson’s 8 Rules for Statistical Process Control (SPC) charts are a set of criteria used to identify patterns that suggest a process may be out of control — even when data points lie within control limits.

These rules guide you in spotting emerging issues, enabling corrective action before defects multiply or downtime escalates. Let’s break them down to see what they reveal and what might be causing the behavior.

Rule 1: One Point Beyond 3 Sigma (Outlier)

Pattern Description: Large shifts from the average

Probable Causes:

- New operator or technician

- Wrong setup

- Measurement error

- Skipped or incomplete step

- Power failure

- Equipment malfunction

Rule 2: Nine Consecutive Points on One Side of the Mean

Pattern Description: Small shifts from the average

Probable Causes:

- Raw material change

- Work instruction update

- Recalibrated measurement devices

- Change in operator or shift

- Growing skill level

- Adjusted maintenance or setup routine

Rule 3: Six Points in a Row Trending Up or Down

Pattern Description: Trends

Probable Causes:

- Tool wear

- Temperature variation (cooling/heating cycles)

Rule 4: Fourteen Alternating Points (Up, Down, Up…)

Pattern Description: Overcontrol

Probable Causes:

- Excessive operator adjustments

- Inconsistent raw materials

Rule 5: Two of Three Points Beyond 2 Sigma (Same Side)

Pattern Description: Large shifts from the average

Probable Causes:

- Measurement or setup error

- Step skipped or incomplete

- Equipment or power issue

Rule 6: Four of Five Points Beyond 1 Sigma (Same Direction)

Pattern Description: Small shifts from the average

Probable Causes:

- Material or instruction changes

- Calibrated device impact

- Learning curve or shift difference

Rule 7: Fifteen Points Within ±1 Sigma

Pattern Description: Stratification

Probable Causes:

- Multiple processes or machines involved

- Masked variation due to grouping data together

Rule 8: Eight Points Beyond ±1 Sigma (Alternating Sides)

Pattern Description: Mixtures

Probable Causes:

- More than one process being measured (e.g., shifts, machines, materials)

Nelson’s Rules offer a practical, proven way to detect early warning signs in your processes. Integrating them into your SPC strategy helps ensure quality, stability, and continuous improvement. They bridge the gap between data monitoring and real-time action — helping you catch problems before they escalate.