Kanban aims to minimize WIP (Work-In-Process), or inventory, between processes by ensuring that the upstream process produces parts only if its downstream process needs them. “Pull” means that the downstream workers withdraw or “pull” the parts they need from their upstream processes.

- What is it: Kanban is a Japanese term meaning “signal.”

- It is one of the primary tools of a Just-In-Time (JIT) manufacturing system.

- It signals a cycle of replenishment for production and materials, i.e. the need for an item.

- This can be considered as a “demand” for products from one step in the manufacturing or delivery process to the next.

- It maintains an orderly and efficient flow of materials throughout the entire manufacturing process with low inventory and work in process.

- The Kanban system usually uses a printed card that contains specific information such as part name, description, quantity, etc.

- However, other devices such as plastic markers (kanban squares) or balls (often golf balls) or an empty part-transport trolley or floor location can also be used to trigger a unit’s movement, production, or supply in a factory.

- In a Kanban manufacturing environment, nothing is manufactured unless there is a “signal” to create a pull system.

- This is in contrast to a push-manufacturing environment where production is continuous.

- Why use it: Kanban maintains inventory levels; a signal is sent to produce and deliver a new shipment as the material is consumed.

- These signals are tracked through the replenishment cycle and bring extraordinary visibility to suppliers and buyers.

- Kanban has become an effective tool to support the running of the production system as a whole. In addition, it proved to be an excellent way to promote improvements because reducing the number of kanban in circulation highlighted problem areas.

- The main benefits of using a Kanban system are:

- Reduce inventory and product obsolescence.

- Reduces waste and scrap

- Provides flexibility in production

- Increases Output

- Reduces Total Cost

- Where to use it: Kanban system is best used in stable manufacturing environments and is most beneficial when high-volume/low-value components are involved, especially if there are long lead times or demand is challenging to forecast. Other materials management systems may be a better option for low-volume and high-value components. Still, there are probably sub-areas where a Kanban system of one form or another will aid in production planning and material control.

- When to use it: To reduce total costs on the factory floor and to bring visibility to waste.

- How to use it: Select the components of Kanban that will work in your facility. Not all parts of Kanban may be appropriate for the products you produce. Kanban may be appropriate for one product and not for another. In some cases, a simple manual Kanban will work well. In other cases, computer automation of Kanban may be the best option. You will need to evaluate your in-house production and suppliers to determine which Kanban options will benefit your facility. Please refer to the package for more information.

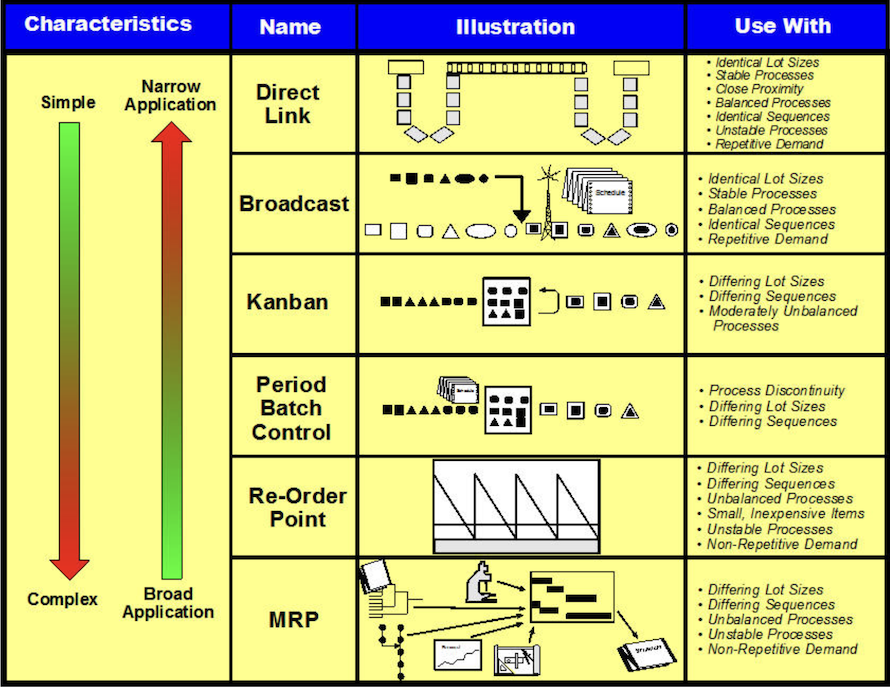

Methods of Production Control

A Hierarchy Of Methodology

- The best system is the simplest.

- Where the process allows, Physical Link is the system of choice. Broadcast, Kanban, MRP and ROP follow in desirability.

- A system designer would examine each process and each product group in turn. He/she attempts to apply physical linkage. If the necessary conditions do not exist and process change is impractical, Physical Linkage is rejected, and Broadcast is considered. This process follows down to the least desirable systems, MRP & ROP.

- In practice, Kanban scheduling systems are often a good choice. They can be a transition between MRP and ROP approaches and Physical Linkage.

- Physical Linking is a way to coordinate. Each part of the process moves in synchronization, and each step starts simultaneously. Processes must have the same lot size and co-location.

- In Broadcast, a final assembly operation builds directly to schedule. The schedule is simultaneously “Broadcast” to upstream subassembly and supply operations. They build the needed parts in “Line-Set Order” with a small time offset for delivery. This system does not require co-location. It does require identical lot sizes (usually one) for all processes.

- Kanban scheduling systems are helpful when lot sizes differ between process steps, processes are unbalanced or when distance introduces time lag or variability. These systems slightly de-couple the processes.

- Re-Order Point (ROP) systems store each item and issue it to downstream work centers on request. ROP signals a resupply when the inventory is just sufficient to cover the resupply time.

- ROP systems are simple. They require steady and predictable withdrawal rates and predictable replenishment times. But these conditions are rare. Typical systems have very high inventories and experience frequent stockouts.

- Materials Requirements Planning (MRP) works from Bills Of Material (BOM), routings, inventory records and forecasts. It plans each process step for each product, subassembly and item. The system accumulates demand for each work center and each period. In theory, MRP allows effective scheduling under the most challenging variability and disconnected process conditions.

- This ability to connect disjointed production comes with a price. MRP permits some forms of sloppy engineering. The administrative costs are high. Throughput times are long, and inventory turns low. Errors in inventory, BOMs or lead times disrupt the system. About 70%- 90% of installed MRP systems do not meet their user’s needs.

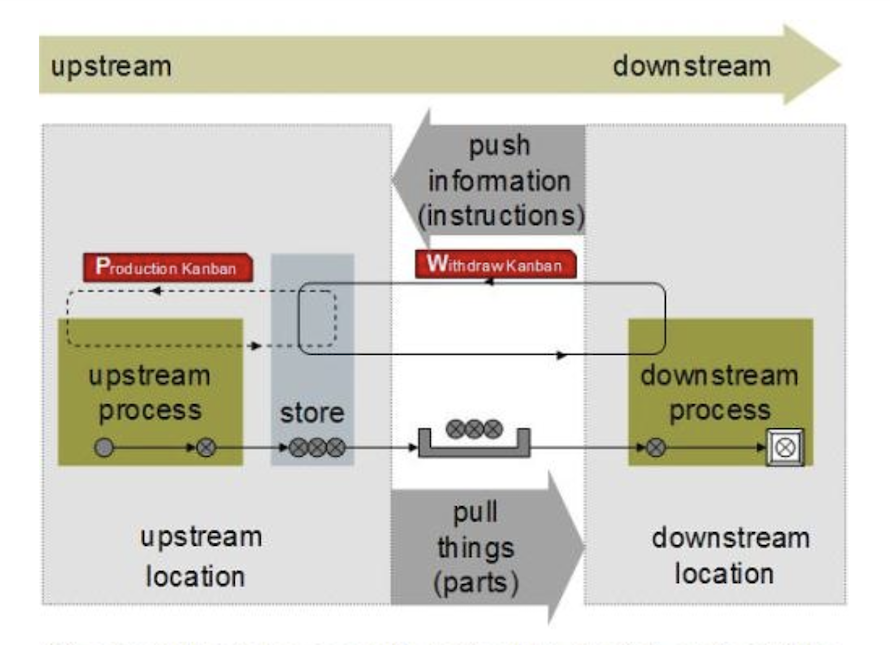

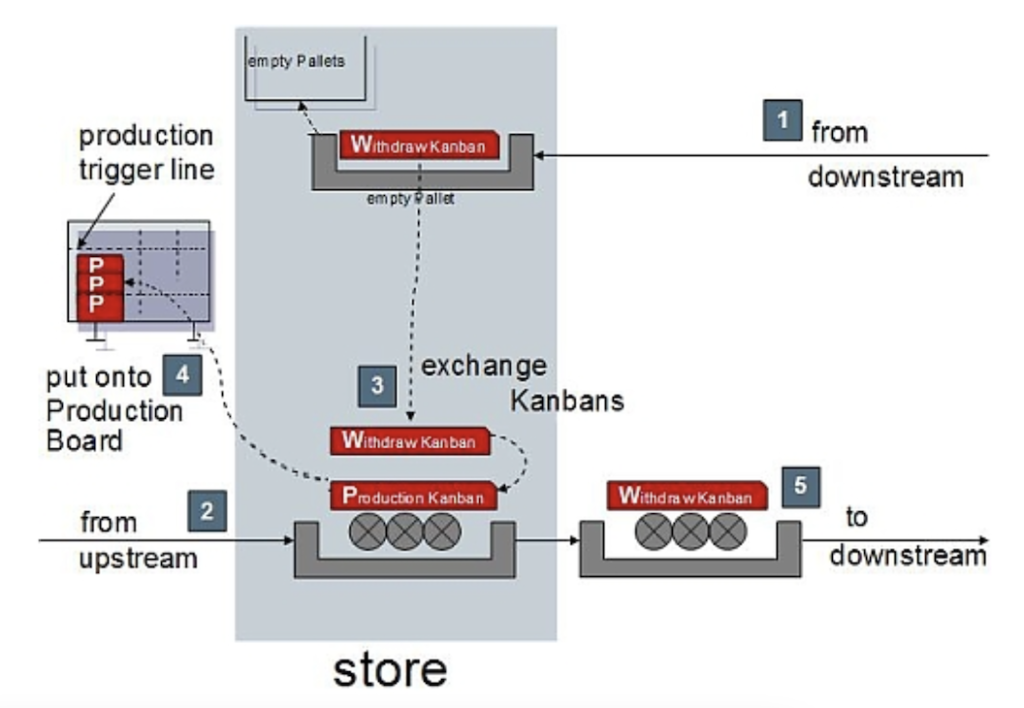

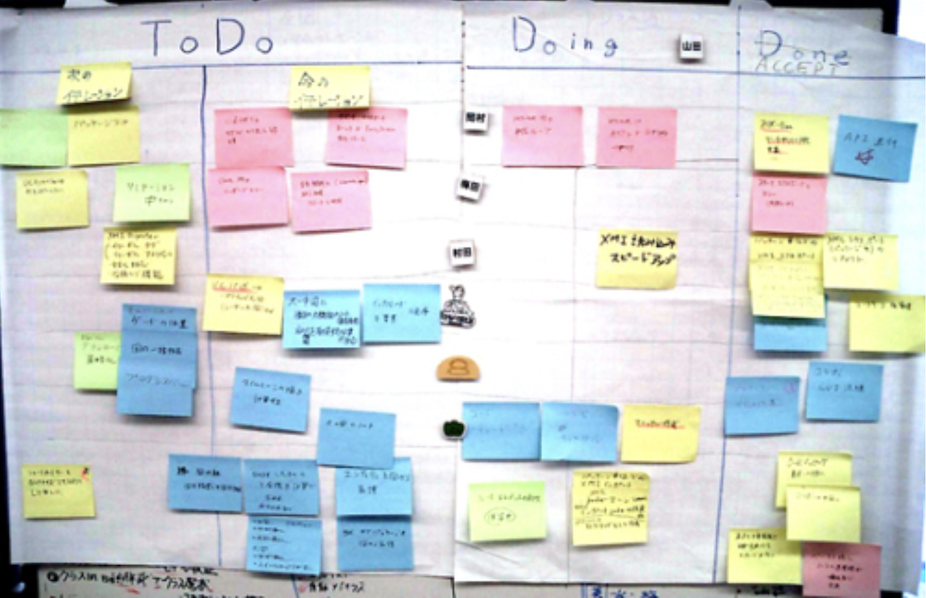

The previous diagram is an abstract model of a Kanban system.

Illustrated are two processes, an upstream and a downstream process, where the upstream process supplies parts (items) to the downstream.

To supply products to the final customer, the process needs to produce parts and make them flow to downstream, but not too much, as overproduction is considered the worst waste.

So to prevent overproduction, the upstream doesn’t “push” finished parts to the downstream; instead, it is the downstream that actively pulls (fetches) the parts from the upstream.

The space where parts are placed is called the “store” (or “supermarket” – Taiichi Ohno got the first idea of Kanban when he visited an American supermarket, where it is not the store clerk but the customer himself who goes to get what he needs in the store).

The store is in the upstream location and works as a “buffer” or a “queue” of WIP. When a worker from the downstream process, called “material handler,” comes to the store and picks up newly finished parts, it also returns a signal of production, i.e. the downstream pulls things from the upstream and simultaneously pushes information to the upstream via Kanban cards.

This is needed because the upstream process never produces parts without instruction from the downstream process.

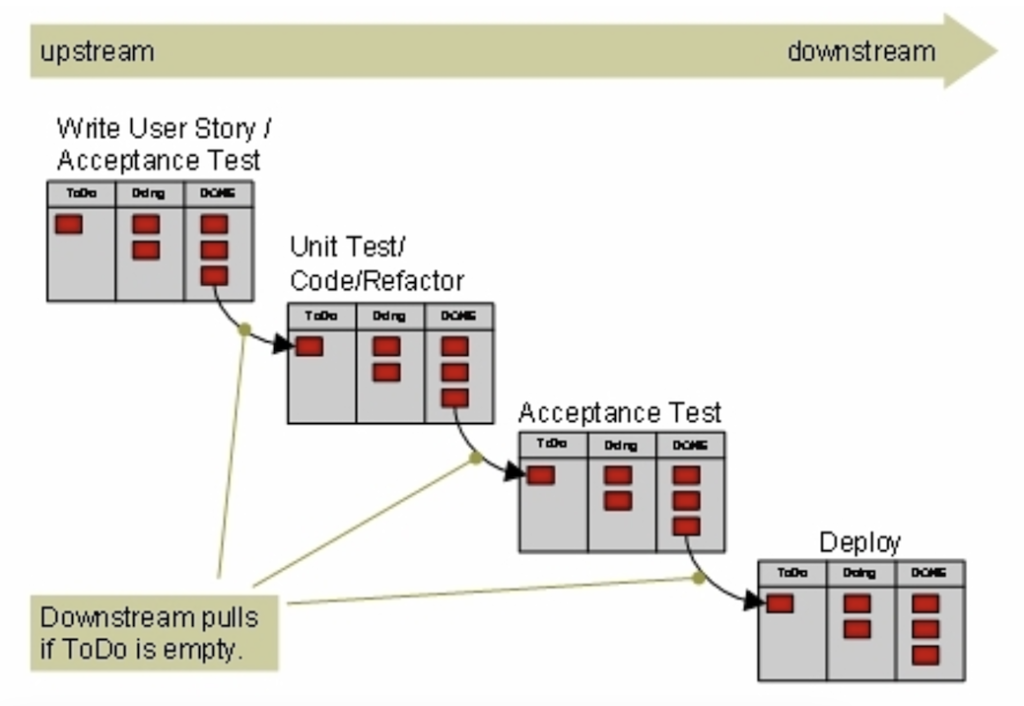

Kanban in Software Development

Kanban in Software Development