What Is Leader Standard Work and Why It Matters

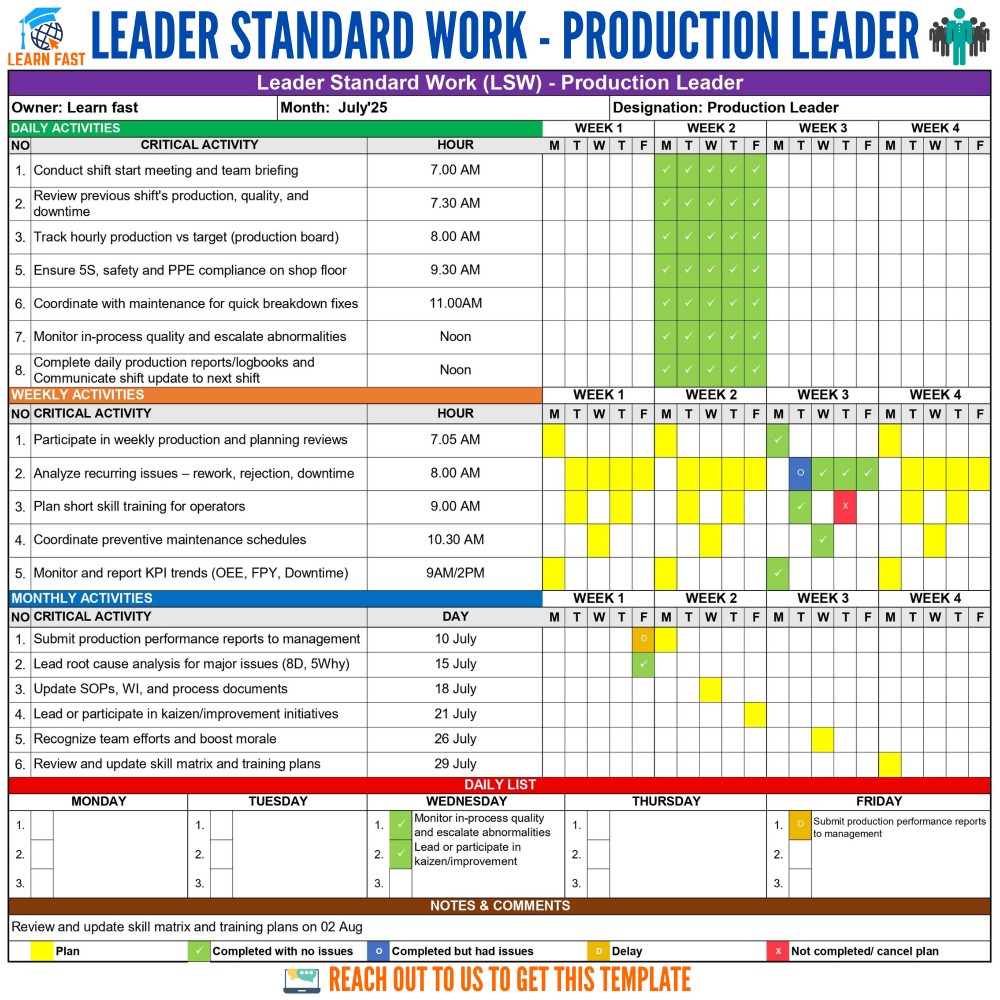

Leadership consistency is just as vital as process consistency. Leader Standard Work (LSW) defines a leader’s routine so that every critical task, safety check, team briefing, problem review, and coaching occurs reliably and at the right time.

It’s not about rigid scheduling. It’s about discipline. A good LSW gives leaders a precise rhythm for the day, week, and month, so that firefighting gives way to prevention, and stress gives way to flow.

You can design your own LSW around three time horizons: daily, weekly, and monthly activities. Let’s break down what they should include.

Daily Activities: Building Control and Engagement

A leader’s day starts long before the first part is produced. Each activity is intentional; it keeps people aligned, equipment reliable, and quality predictable.

✅ Start with a Shift Briefing

Gather your team to review the day’s targets, safety reminders, and any special instructions. Keep it short and visual. A good briefing sets focus and energy for the shift.

✅ Review the Previous Shift

Look at production numbers, downtime, and quality performance. Don’t just read data—ask “why.” This reflection prevents recurring issues and strengthens communication across shifts.

✅ Track Hourly Output vs Target

Visual tracking boards help spot deviations early. If a drop occurs, act quickly; don’t wait until the end of the shift. This turns problems into opportunities for coaching.

✅ Reinforce 5S, Safety, and Standards

Walk the shop floor. Check organization, safety, and PPE compliance. Show your presence not as an inspector but as a coach, reinforcing good habits.

✅ Coordinate with Maintenance

Work hand-in-hand with technicians to address small issues before they grow. Regular touchpoints prevent downtime and build trust between departments.

✅ Monitor Quality at the Source

Check in-process quality and engage operators in problem detection. When they own the quality, you build capability, not dependency.

✅ Log and Communicate Results

Before handing over to the next shift, summarize the day’s performance and any open issues. Document it visually or digitally—it’s how you build continuity between teams.

Weekly Activities: Moving from Reaction to Prevention

Weekly routines connect the dots between daily actions and broader improvements. These are the reflection points that keep your system evolving.

✅ Hold a Short Production Review

Meet with your peers or cross-functional teams. Review key performance indicators: output, quality, and downtime, and identify recurring trends. Keep the focus on facts, not opinions.

✅ Analyze Recurring Losses

Use Pareto charts or 5-Why analysis to focus your energy. A weekly review of rework, rejections, or delays helps convert raw data into root causes and countermeasures.

✅ Plan Operator Skill Development

Your team’s skill set defines your flexibility. Identify where operators need training and schedule short, focused sessions. A trained team is your best safeguard against variation.

✅ Coordinate Preventive Maintenance

Work with maintenance teams to confirm PMs are completed. Production and maintenance coordination is one of the strongest predictors of uptime and efficiency.

✅ Monitor KPI Trends

Set a rhythm to review OEE, FPY, and downtime patterns. Use graphs, not spreadsheets. The goal is visual clarity that sparks action.

Monthly Activities: Sustaining the System

Monthly actions shift focus from control to improvement and culture-building.

✅ Submit or Review Performance Results

Summarize production outcomes, highlight progress, and identify areas for improvement. It’s not just reporting, it’s communicating your system’s health.

✅ Conduct Root Cause Analyses for Major Issues

When chronic problems persist, use structured problem-solving methods (like 8D or 5-Whys). Capture learnings and share them. Root cause thinking builds maturity.

✅ Update SOPs and Work Instructions

Standards evolve. Review and update your procedures to reflect the most effective method. Visual work standards prevent knowledge gaps.

✅ Lead or Support Kaizen Activities

Pick one improvement focus per month. It could be reducing changeover time, improving 5S, or eliminating a minor recurring defect. Small wins compound fast.

✅ Recognize Team Efforts

Acknowledge improvement ideas and safe behaviour. Recognition fuels motivation; it turns compliance into commitment.

✅ Review Skill Matrix and Training Plans

Check your team’s progress. Who can run multiple machines? Who needs mentoring? Skill versatility supports flexibility and morale.

How to Create Your Own LSW

1️⃣ Start Small – Don’t overcomplicate it. Start with a few daily and weekly actions that make the most significant difference.

2️⃣ Visualize Your Routine – Use a simple Excel sheet or whiteboard to track your completion. Visibility builds accountability.

3️⃣ Standardize and Reflect – At the end of each week, review what worked and what didn’t. Adjust your plan, LSW should evolve, not freeze.

4️⃣ Coach Your Successors – Share your routine with your team leaders. When LSW cascades down, the organization gains true stability.

The Real Benefit

Leader Standard Work doesn’t just manage the process; it develops the people who run it. It transforms leadership from “doing everything yourself” to “enabling everyone else to succeed.” Over time, this habit forms the backbone of a Lean culture that is steady, visible, and relentlessly improving.

When leaders follow LSW with discipline, they don’t just track production—they build the system that sustains it.