How to Calculate Machine Hour Rate for Accurate Costing

Understanding Machine Hour Rate (MHR): Why It Matters

Ever wondered why two companies with similar products have drastically different profit margins? The secret often lies in their understanding of costs—especially machine costs.

One of the most critical metrics in manufacturing is the Machine Hour Rate (MHR). It answers a simple yet powerful question: How much does it cost to run a specific machine for one hour?

Getting this right means:

- Accurate product costing

- Competitive job pricing

- Better budgeting and forecasting

- Identifying inefficiencies and reducing waste

What Is Machine Hour Rate?

Machine Hour Rate represents the total cost of operating a machine for one hour, considering all relevant expenses. This includes:

- Standing Charges (Fixed Costs): Costs that remain constant, such as depreciation, insurance, and rent.

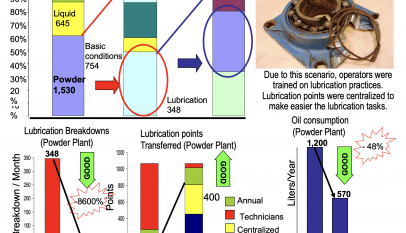

- Running Costs (Variable Costs): Costs that fluctuate with usage, such as power, lubricants, and maintenance.

This metric helps manufacturers avoid underquoting jobs and ensures every quote reflects actual operating costs.

Steps to Calculate Machine Hour Rate

Here’s a structured approach to determine MHR:

- Identify the Machine: Choose the machine for which you want to calculate the hourly rate—this could be a CNC machine, lathe, or any other production equipment.

- Gather Essential Data:

- Purchase cost of the machine

- Expected useful life

- Estimated scrap value (if any)

- Operating hours per year

- Operator wages (if dedicated to the machine)

- Calculate Total Machine Hours Available: Example: If your machine operates 8 hours a day for 250 working days, total annual machine hours = 8 × 250 = 2,000 hours.

- Determine Standing Charges (Fixed Costs): Include depreciation, insurance, factory rent allocation, supervision, lighting.

- Determine Running Costs (Variable Costs): Include power consumption, lubricants, maintenance, operator wages (if variable).

- Apply the Formula:

Machine Hour Rate (MHR) = (Standing Charges + Running Costs) ÷ Total Machine Hours

Example (Generalized)

Let’s calculate MHR for a milling machine:

- Fixed Costs (Standing Charges): Depreciation, insurance, rent allocation, supervision = $20,000/year

- Variable Costs (Running Costs): Power, lubricants, maintenance = $10,000/year

- Total Annual Cost: $30,000

- Total Machine Hours: 2,000 hours

MHR = 30,000 ÷ 2,000 = $15/hour

Why Is MHR Critical?

Ignoring or miscalculating MHR can lead to:

- Underquoting jobs: Losses

- Overpricing: Losing bids

Accurate MHR means: Smarter decision-making, stronger profitability, and better resource planning.

Common Mistakes to Avoid

- Excluding downtime in machine hours (Always account for realistic operating hours).

- Ignoring hidden costs like preventive maintenance.

- Using outdated data for depreciation or energy costs.

Final Thoughts

Machine Hour Rate is more than just a formula—it’s a financial lens for operational excellence. When applied consistently, it transforms costing from guesswork into precision.

So, what’s your approach to calculating machine costs? Do you use traditional costing or activity-based costing? Share your thoughts below!