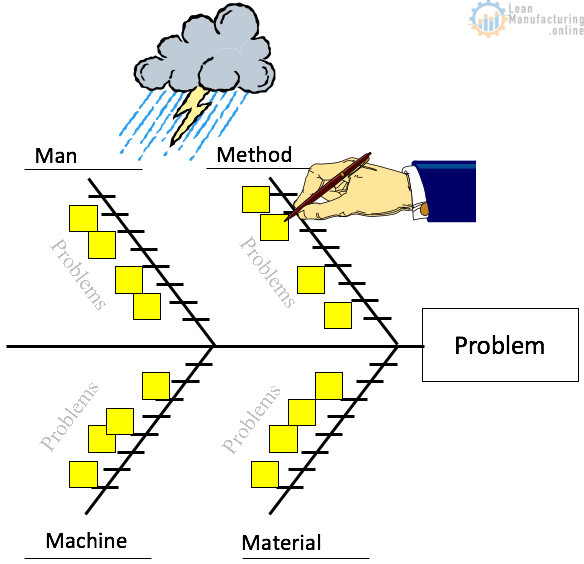

P dash M Analysis is a systematic Problem-Solving Philosophy for Chronic Losses. The term P-M Analysis comes from the following origin: P – Phenomena(non), Physical; M – Mechanism, Relationship (Machine, Man/Woman, Material, Method)

When To Use P-M Analysis?

Root Cause Analysis

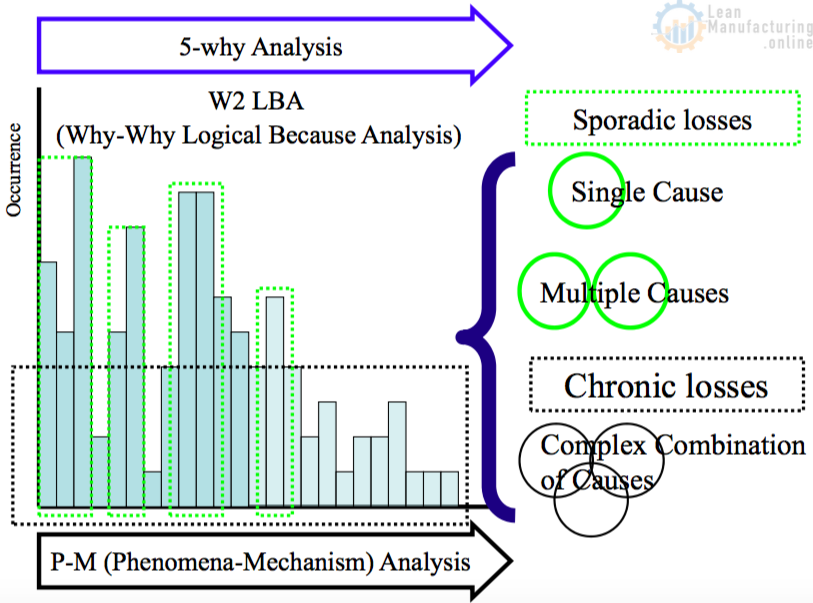

Two Types of Problem Solving Techniques

Why is the 5-why Analysis effective?

Example

Problem: No.1 conveyor stopped.

What is Actually happening (Phenomenon):

Overload and the fuse blew.

Why-1 Why was there an overload?

The bearing was not sufficiently lubricated.

Why-2 Why was it not lubricated sufficiently?

The lubricating pump was not pumping.

Why-3 Why was it not pumping sufficiently?

The shaft of the pump was worn and rattling.

Why-4 Why was the shaft of the pump was worn and rattling.

There was no strainer attached and metal scrap got in.

Why-5 Why was no strainer attached?

There are no checking rules.

Action is taken for Root-Cause

|

Why |

Answer (Observation) |

Action |

|

Why was there an overload? |

The bearing was not sufficiently lubricated. Logical linkage is required |

the bearing was replaced. |

|

Why was it not lubricated sufficiently? |

The lubricating pump was not pumping. Logical linkage is required |

The lubrication pump was checked. |

|

Why was it not pumping sufficiently? |

The shaft of the pump was worn and rattling. |

The shaft of the pump was replaced. |

|

Why was the shaft of the pump was worn and rattling? |

There was no strainer attached and metal scrap got in. |

The strainer was attached and cleaned up the lubrication tank. |

|

Why was no strainer attached? |

There are no checking rules. |

An Autonomous Maintenance standard has been developed. |

How can we identify what is actually happening?

Problem

Do’s

- Identify specific problems, which is the deviation between our expectations and actually happening.

Don’ts

- Before identifying specific problems, jump to action.

- Talking with just feeling.

The 5-why analysis must be used when to identify “ Phenomenon” What is “Phenomenon”.

Phenomenon

Is (What is actually happening)

- The fact you observed with your eyes and numeric data.

- The fact without presumption

Is Not

- Your own opinion, feeling.

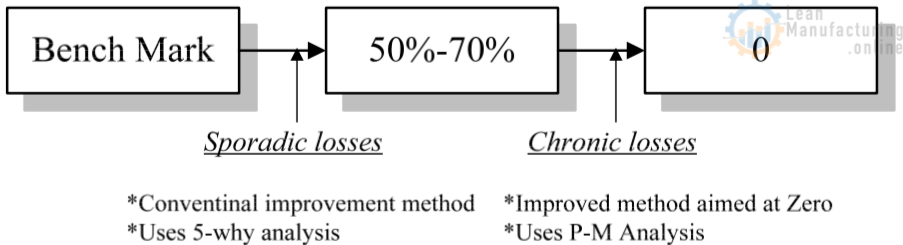

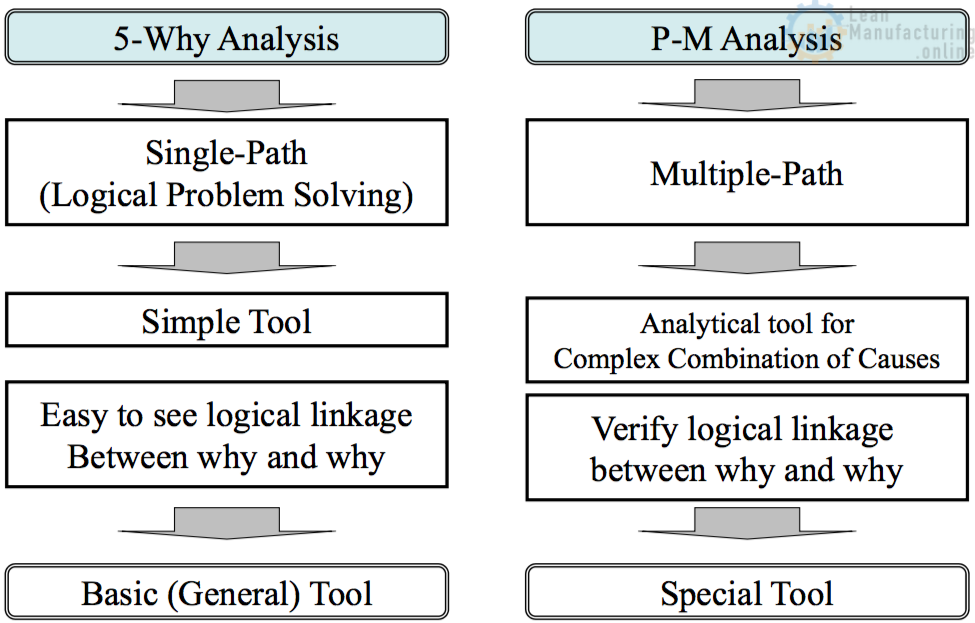

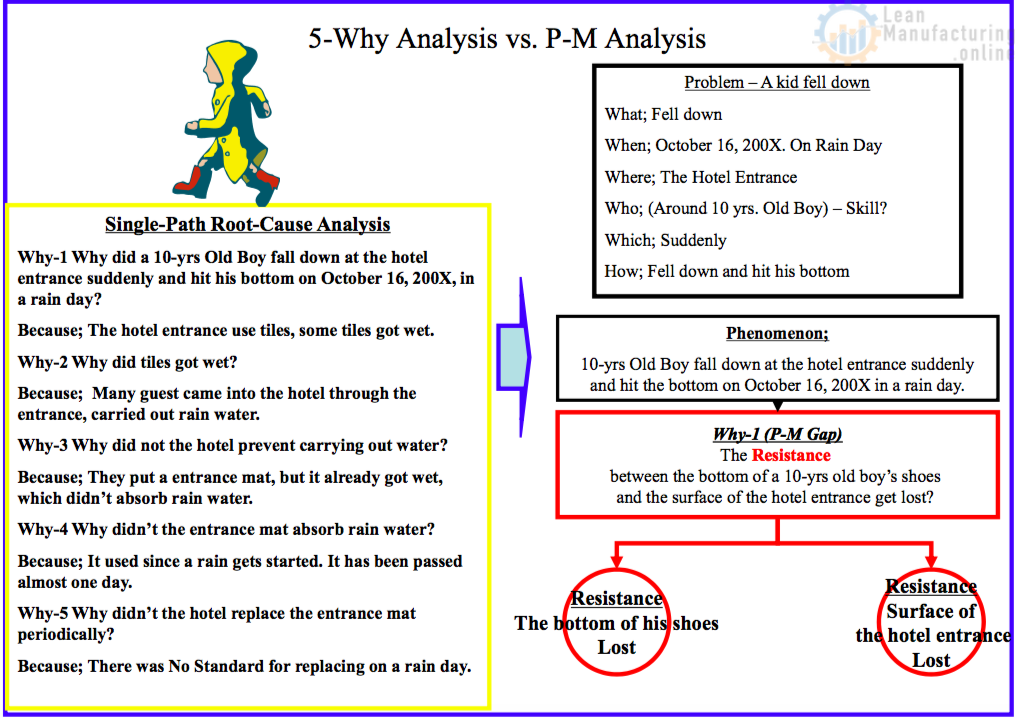

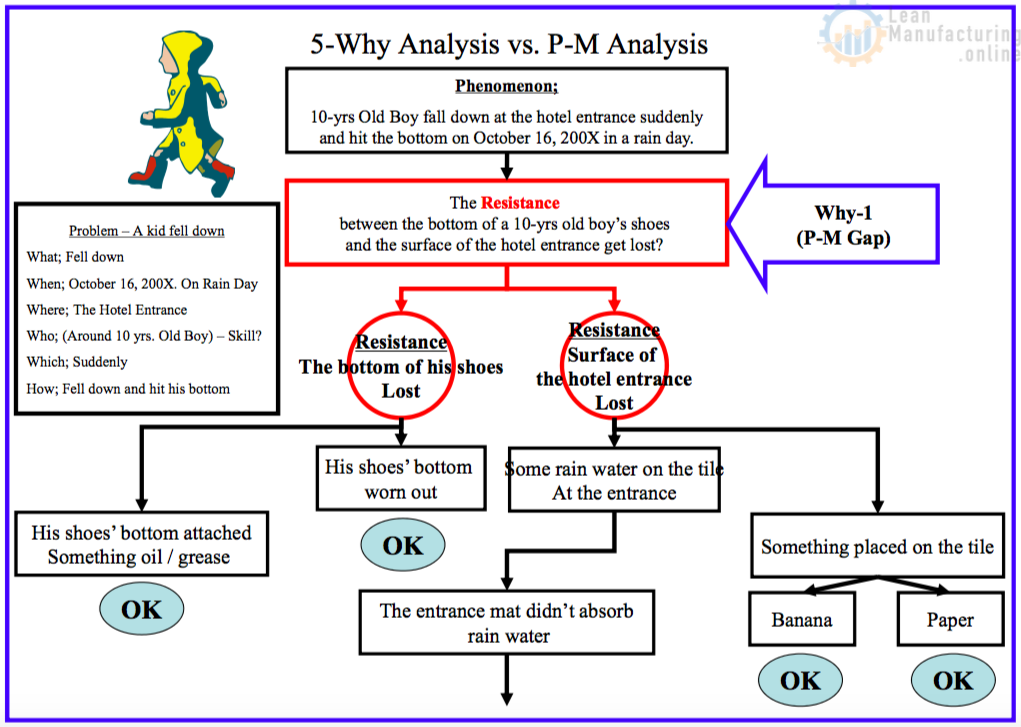

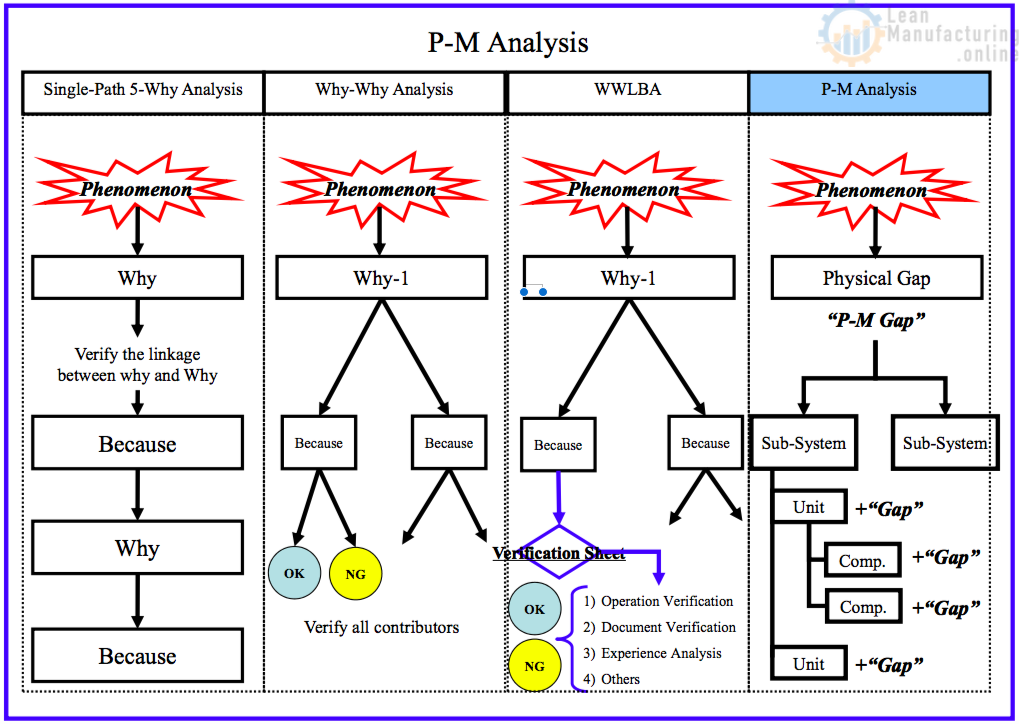

5-Why Analysis vs. P-M Analysis

Features in P-M Analysis

|

P-M Analysis (Multiple-Path) |

5-Why Analysis (Single-Path) |

|

|

Phenomenon Statement (Analysis Start-Point) |

– The same step requires identifying the “Phenomenon”. |

|

|

Logical Linkage |

– Describe All Possible factors. – In order to describe all possible factors, Recommend setting up the “P-M Gap” Statement. |

– Describe clearly Why & Answer (because). |

|

Verification Process |

– Identify and describe All Possibilities first, and then verify which factors can contribute to the above possibility (“Gap from Principle of Operation”) -Identify “Gap” instead of “Why” |

– Before moving the next why require to verify (capture) the evidence. – You say “Why”, capture the “evidence”. -You can say “Because …” |

|

Key Points for Use |

– Understand the differences between “Fish-Bone Analysis” and/or “Why-Why Analysis” |

– Show the “evidence” before moving to the next why. |

|

Who should use |

– The higher Team Leaders’ Level. – Since AM Step-4 |

– All Employee |

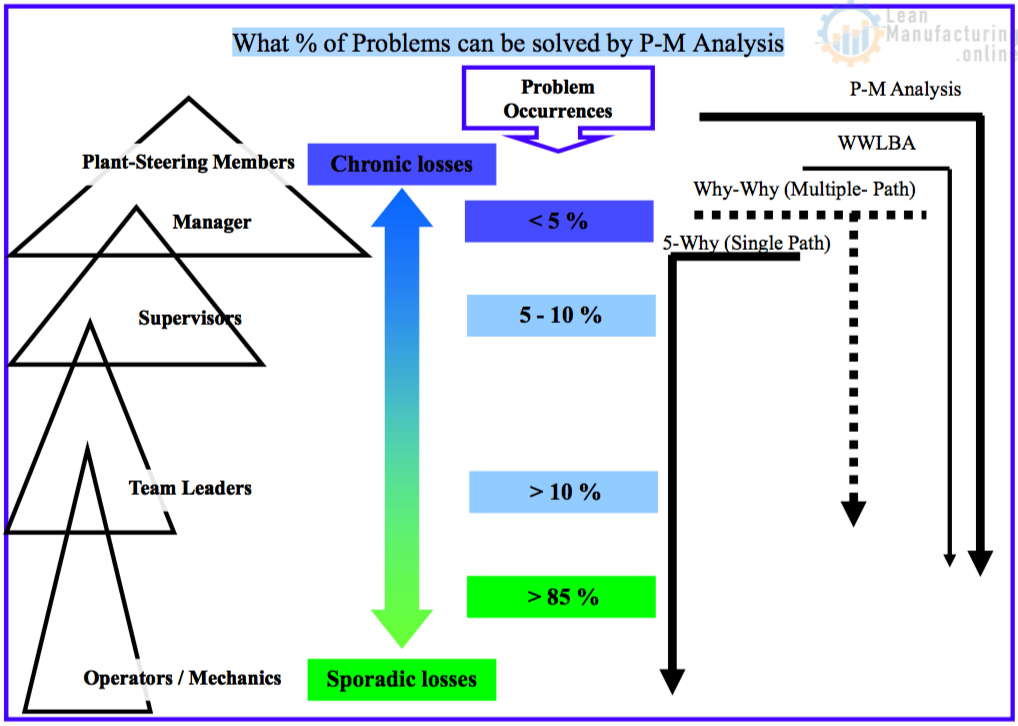

P-M Analysis

What % of Problems can be solved by P-M Analysis

Steps of P-M Analysis

|

P-M Analysis Step |

Activity |

Key Learning |

|

Step-1 |

Clarify the Phenomenon |

Phenomenon Statement |

|

Step-2 |

Examine-in terms of Physical Principle Involved |

P-M Gap |

|

Step-3 |

Analyze Contributing Conditions |

Principle of Operation |

|

Step-4 |

Study the relationship between 4M’s |

Machine Structure & Function Diagram |

|

Step-5 |

Study of what the conditions must be |

Optimal Conditions |

|

Step-6 |

Study of investigation methods |

Machine Diagnosis Technique & Measurements |

|

Step-7 |

Find out All Potential Abnormalities |

|

|

Step-8 |

Implement & Plan Countermeasures |

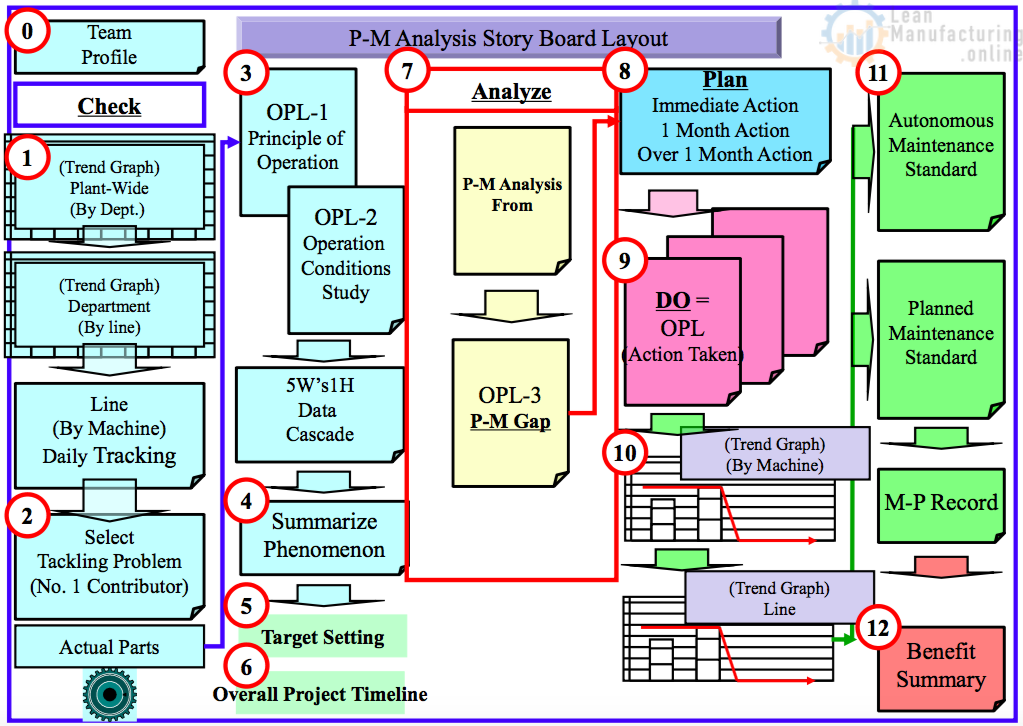

P-M Analysis Story Board Layout

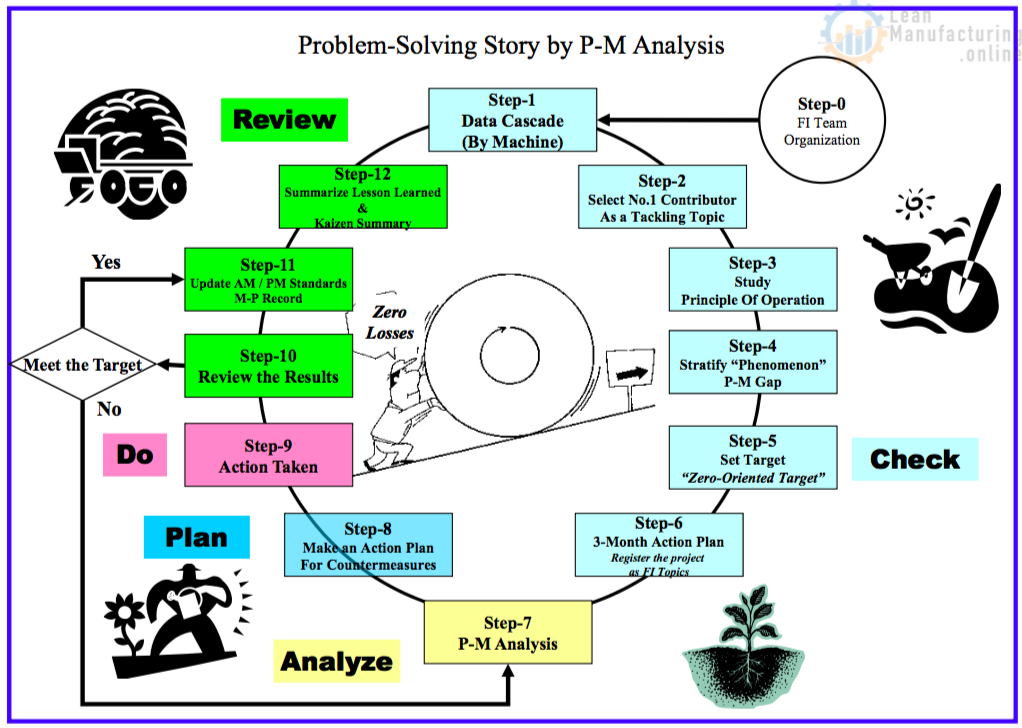

Problem-Solving Story by P-M Analysis

CAP-Do Cycle & P-M Analysis

|

CAP-Do Cycle Process |

P-M Analysis Step |

||

|

Check |

1-1 Analyze the “Gap” between Target and Actual situation. 1-2 Prioritize No.1 Contributor as FI Theme (Topics) 1-3 Stratify Problem into Phenomenon |

Step-1 |

Clarify the Phenomenon |

|

Step-2 |

Examine-in terms of the Physical Principle involved. (P-M Gap) |

||

|

Analyze |

2-1 Principle of Movement (Processing) -Identify the “Gap” between the Principle of Processing and Actual Conditions. -Step-1 to Step-7 |

Step-3 |

Contribute Conditions |

|

Step-4 |

Study the relationship between 4M’s |

||

|

Step-5 |

Study of what the condition must be (Optimal Condition) |

||

|

Step-6 |

Study of investigation method |

||

|

Step-7 |

Point out Abnormal Conditions |

||

|

Plan |

3-1 Develop an Action Plan |

Step-8 |

Implementation and plan of improvement |

|

Do Review |

4-1 Take action for each cause and Root- Cause 4-3 Verify the result in 3 months (90 days) 4-4 Feedback the points of sustaining (maintaining) * Review the Results (Benefit) |

||