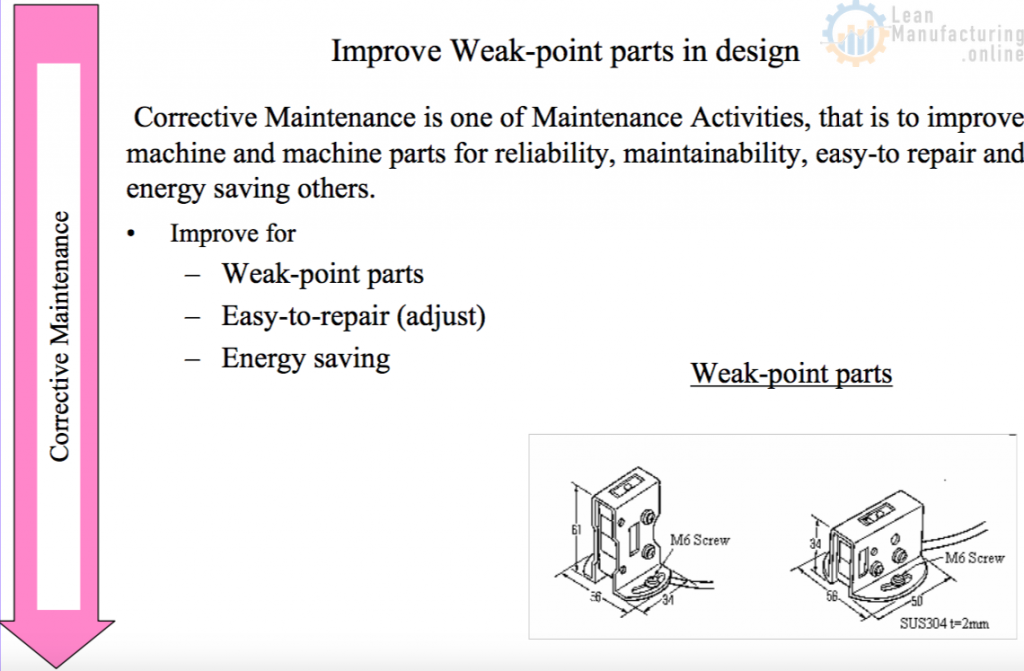

Corrective Maintenance-1

Corrective Maintenance-2

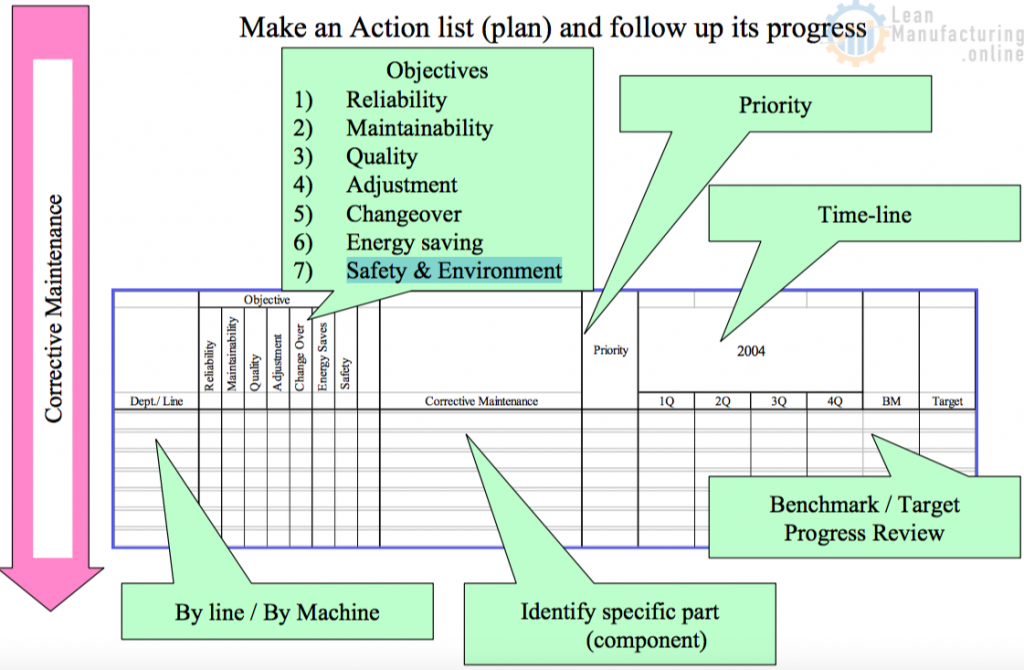

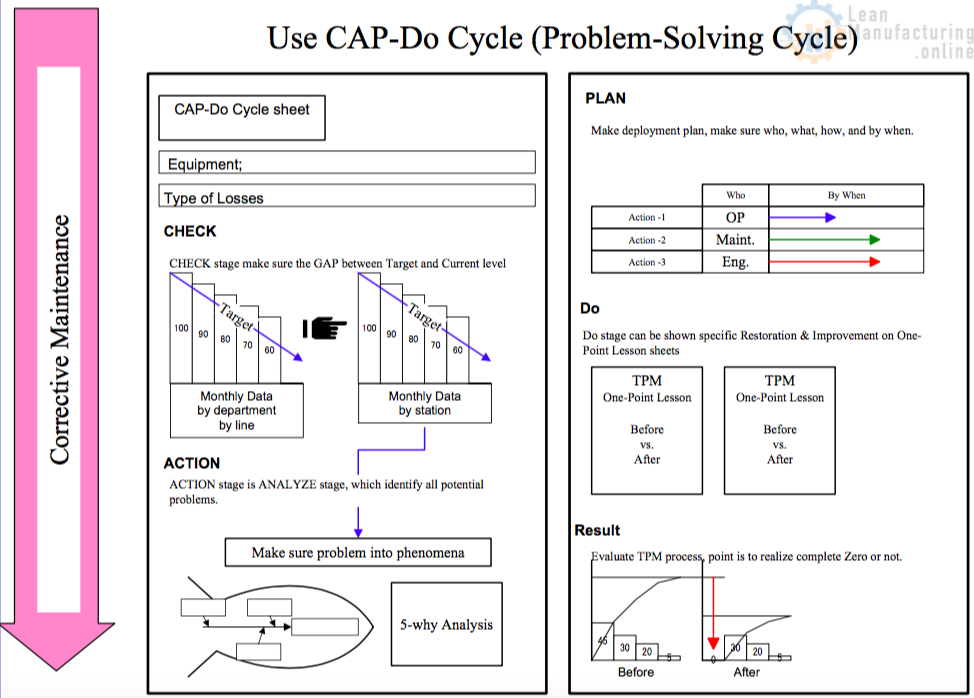

Corrective Maintenance-3

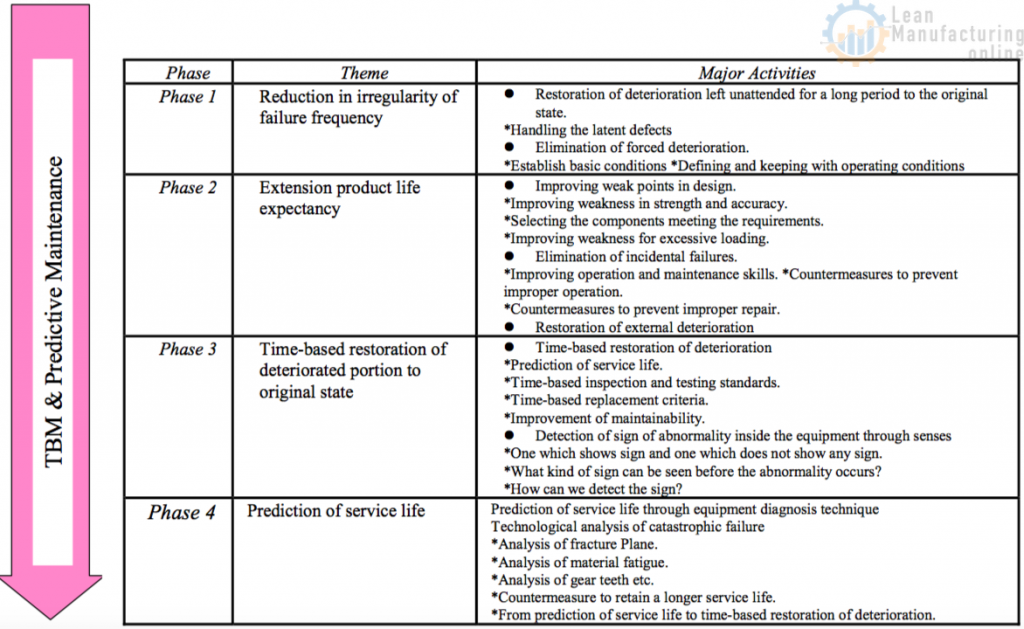

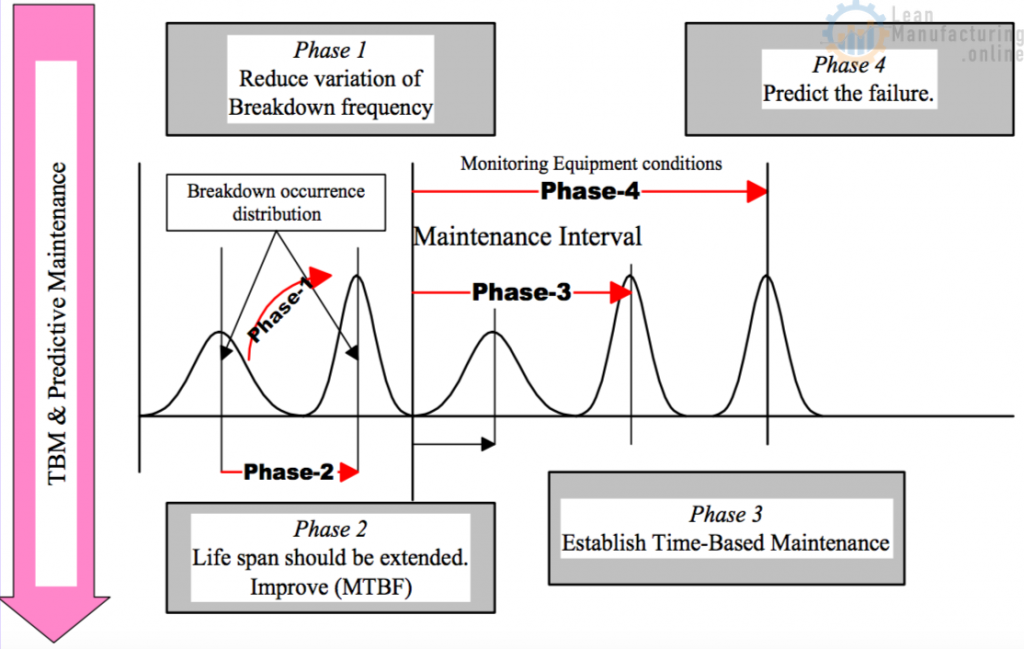

4 phases approach for Zero-Breakdown

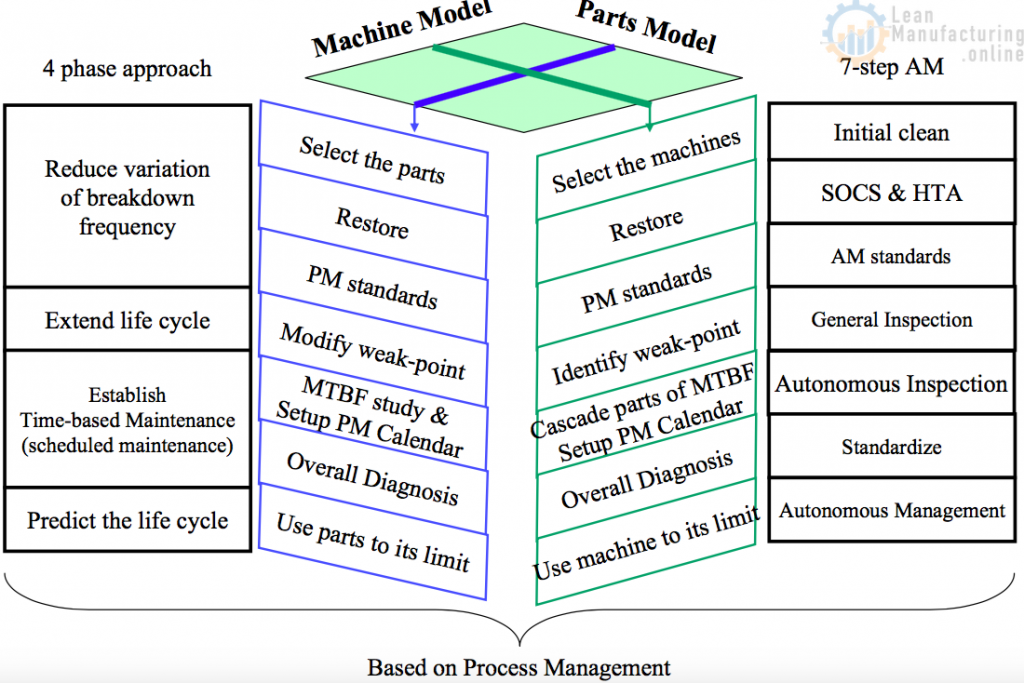

Equipment Model & Parts Model

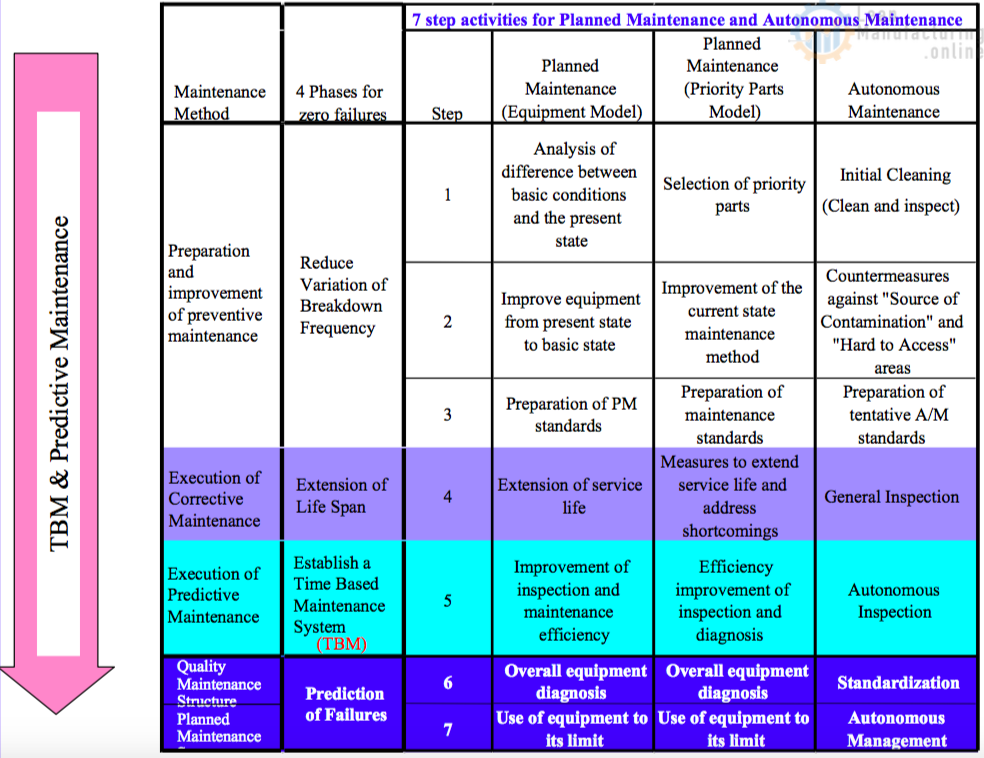

7 step activities for Planned Maintenance and Autonomous Maintenance

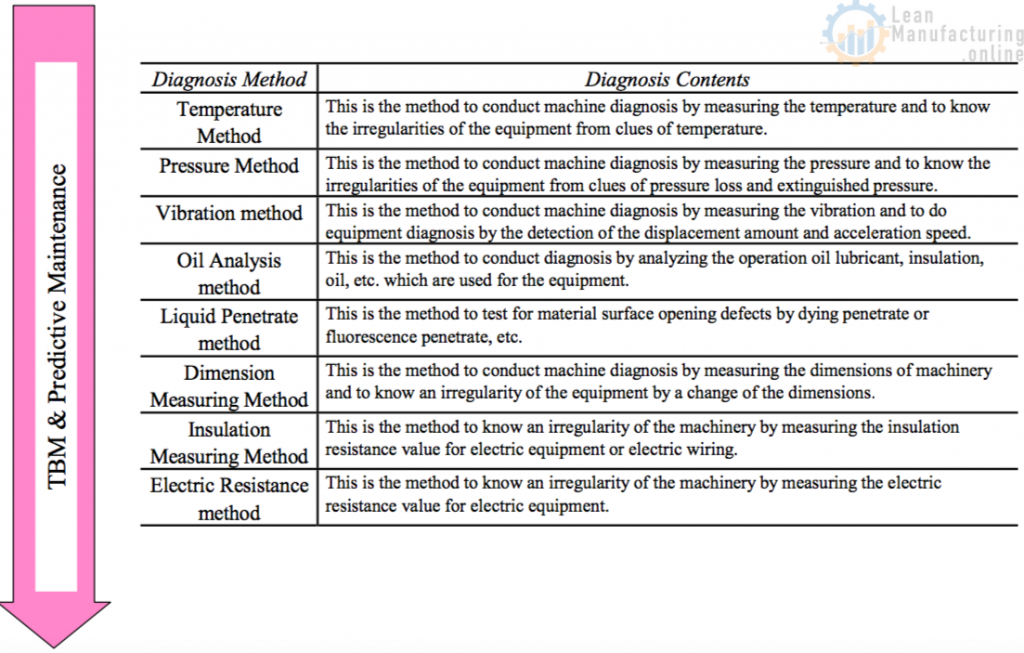

Predictive Maintenance

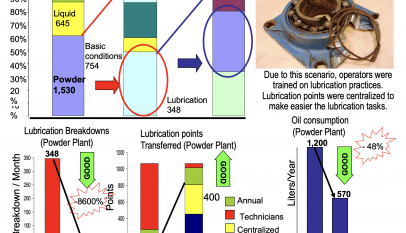

- On the actual condition of preventive maintenance, as there are problems in the decision of overhaul and repair timing of equipment, it frequently becomes over-maintenance or sporadic accident occurs. The way to solve these situations is preventive maintenance.

- This is to survey the mechanism of failure or deterioration of equipment thoroughly or to diagnose the running condition, and to conduct the maintenance depending on the situation.

- As a tool to realize predictive maintenance, machine diagnosis technique is very important.

- Today, there is a tendency to orient the predictive maintenance by the research and development of equipment diagnosis technique, but which maintenance style is adopted should be determined by the balance of investment in maintenance and the profit generated by the production.

Examples of Predictive Maintenance

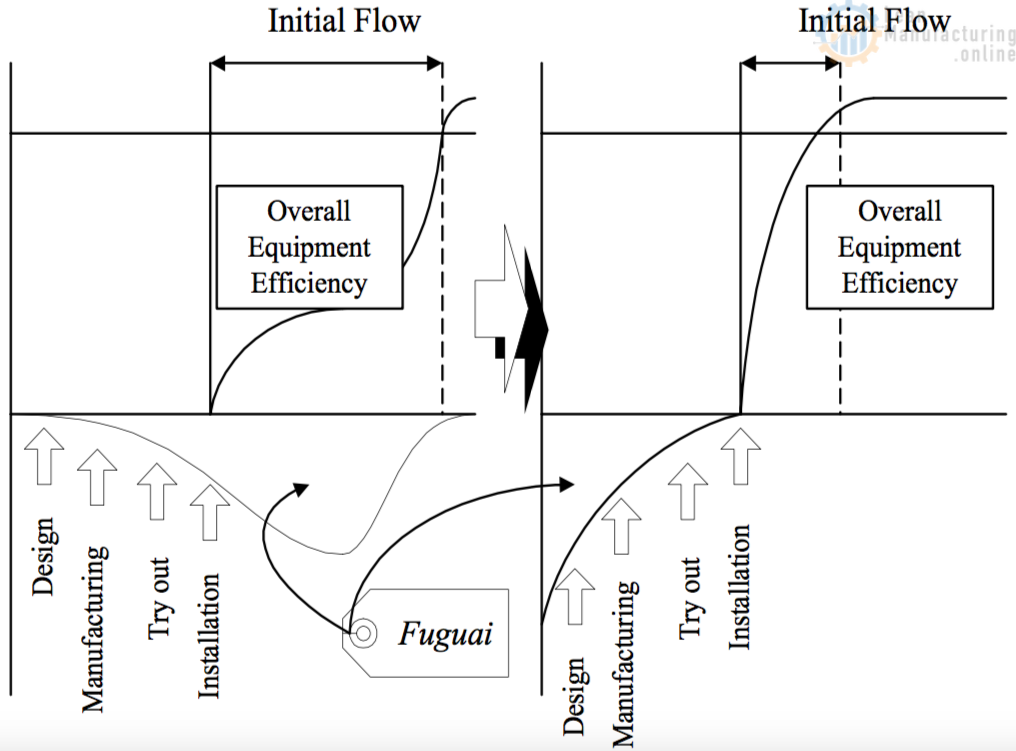

M-P Design – Vertical Start-up

Activities to reduce maintenance cost and deterioration-caused losses taking into consideration reliability, maintenance, economical efficiency, operability, safety and other factors by incorporating maintenance information and new technologies in the stage to correctly plan and design equipment.

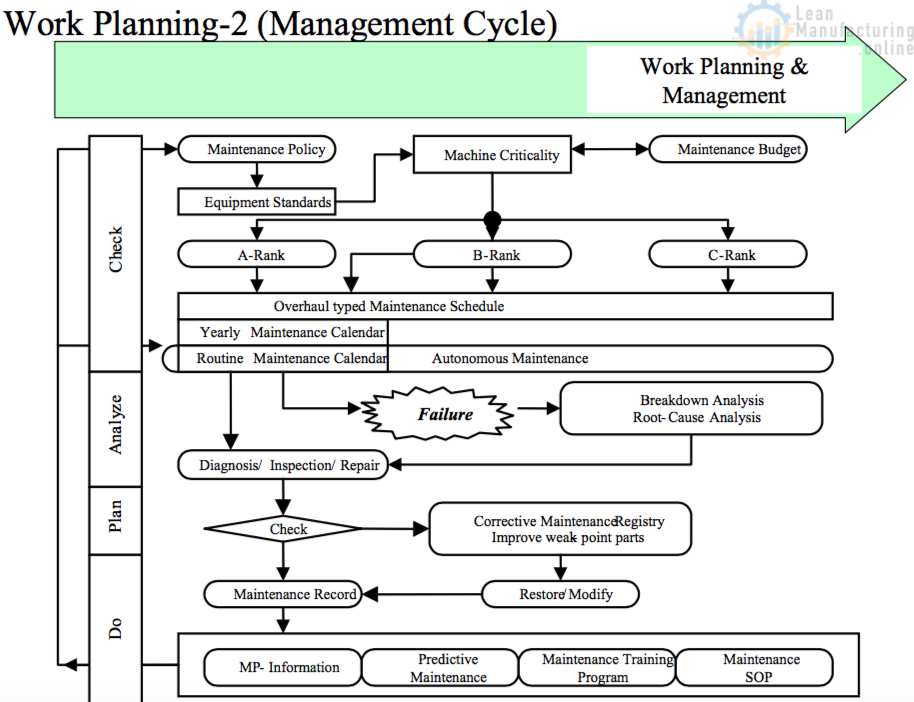

M-P Information

M-P Information means engineering information for a manufacturing workshop, obtained by conducting technological study, classification, and refinement of improvement records and latent nonconformity of existing equipment, in order to better suit M-P design.

RELIABILITY (MTBF , MTTF …)

- Easy to keep the Basic conditions

- (Cleaning , Lubricating , Fastening)

- Screening weak-points of parts, unit, system

- Redundancy

- Easy to discovery and predict deterioration

- Operability

- Fool Proof / Fail Safe

- Interface

Maintainability (MTTR ,…)

- Detectability

- Easy to Disassemble

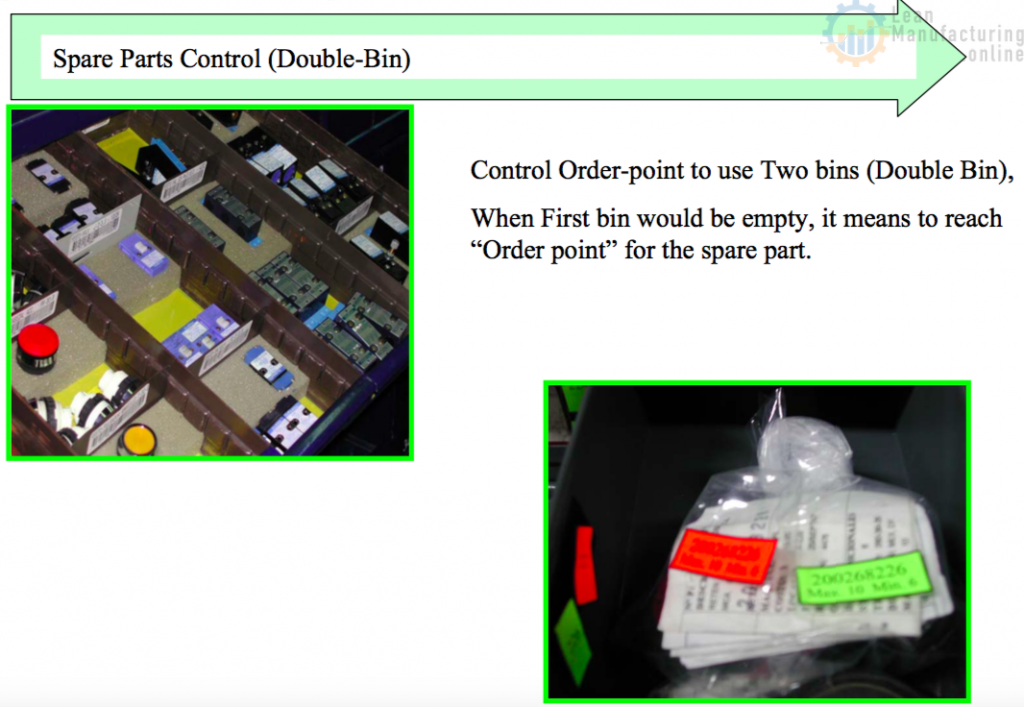

- Spare Parts Control

- Easy to assemble & Adjust

- Autonomous Maintainability

Easy To set up & adjust

Safety

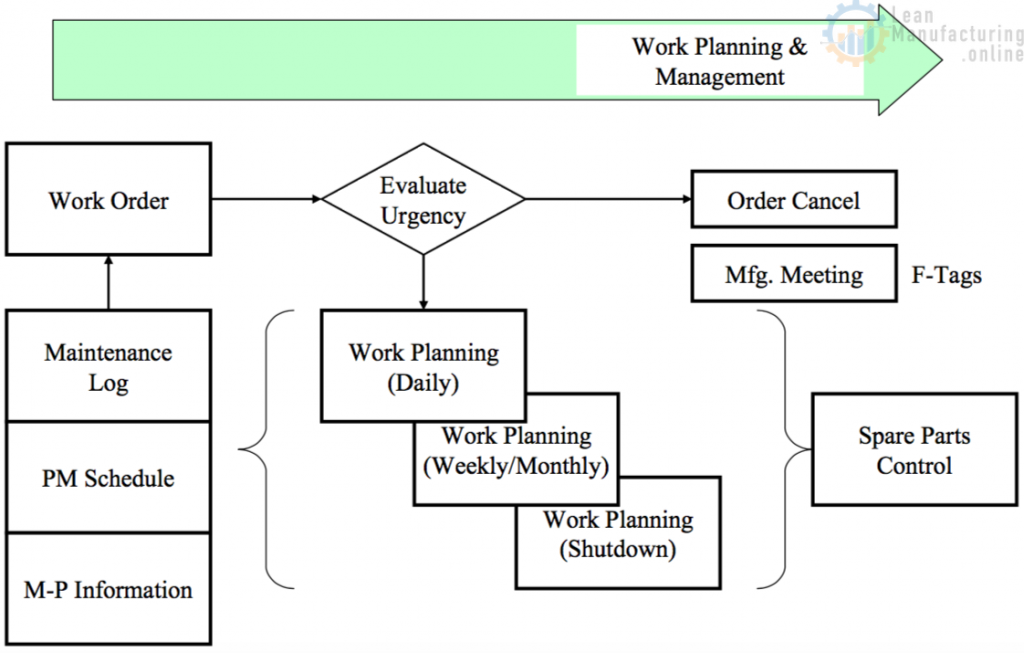

Work Planning-1 (Work Order flow)

Work Planning-3 (Review)

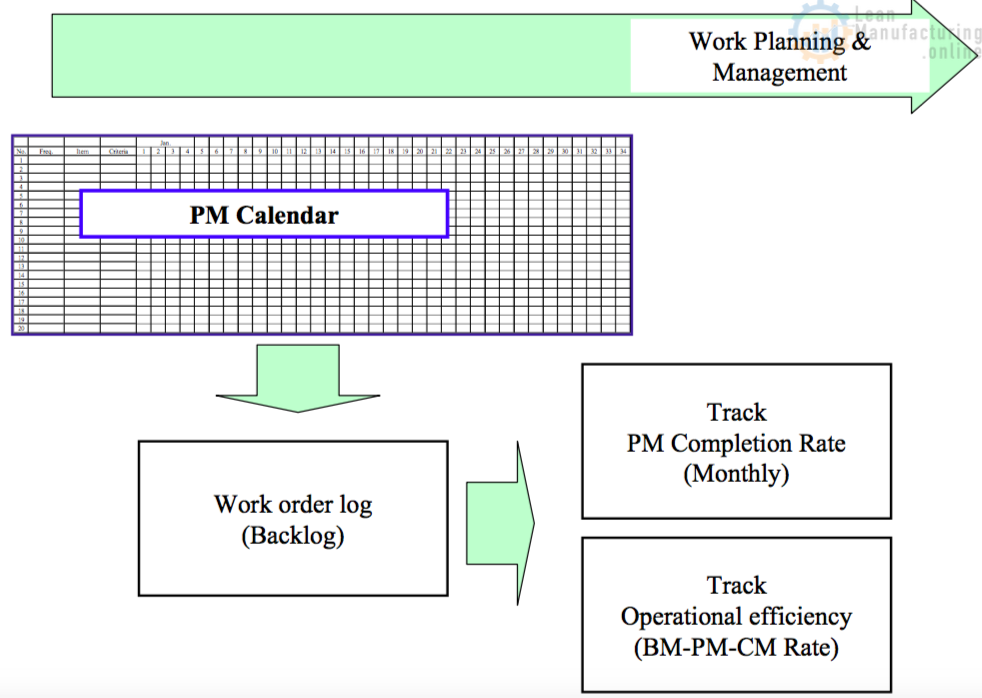

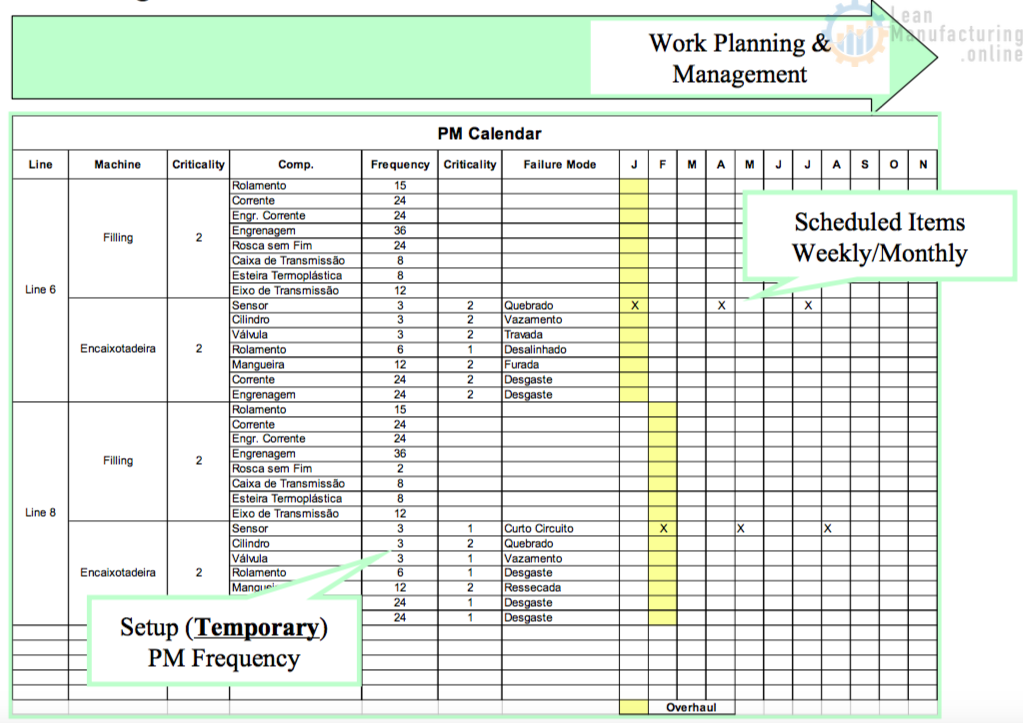

Work Planning-4 PM Calendar

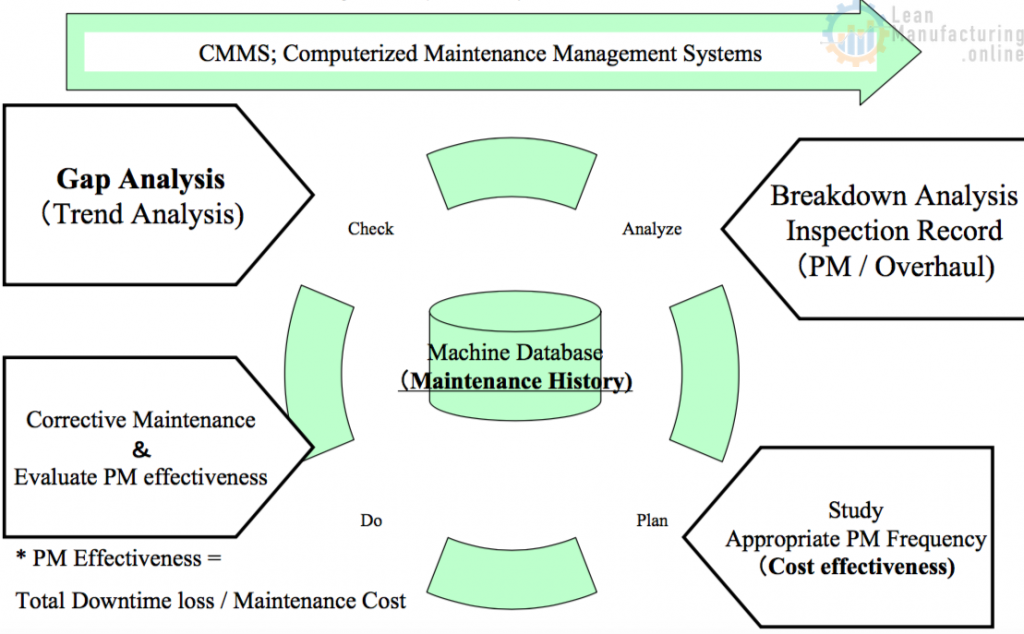

Maintenance Information System (CMMS)

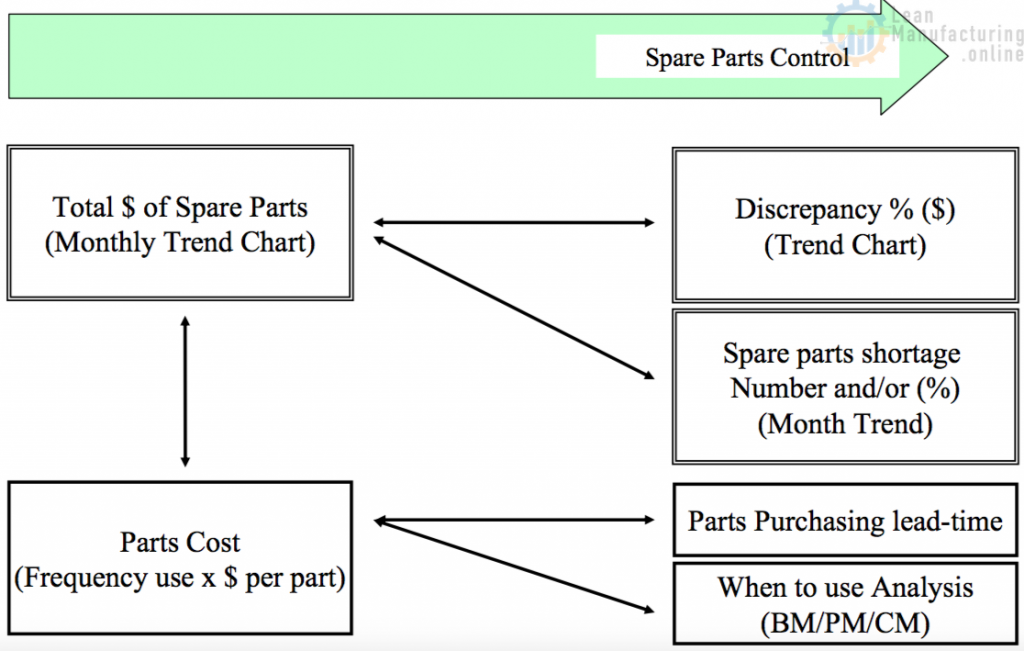

Spare Parts Control (Measures)

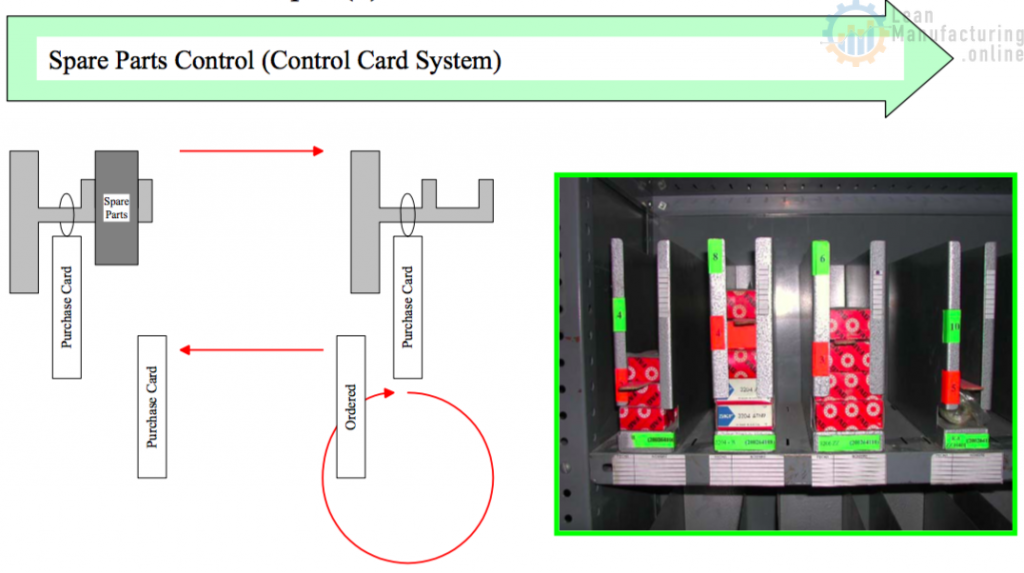

Spare Parts Control Example-(1)

Spare Parts Control Example-(2)

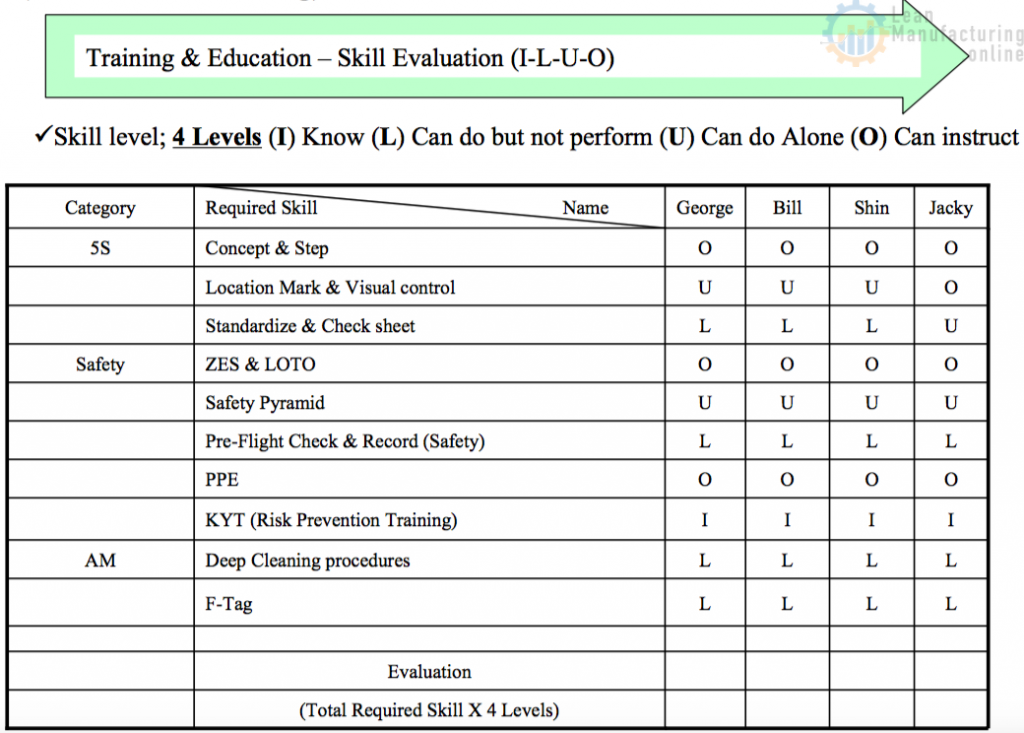

Maintenance Training

Excellent. Thanks