What “Right First Time Changeover” means?

- RFT Changeover

- The structure of Changeover operations

- Preparation;

- Operations to bring and to look for hand-tools, jigs, all tools for changeover and include material loading & unloading operations.

- Setup;

- Operations to exchange jigs, guides, etc. from one thing to another.

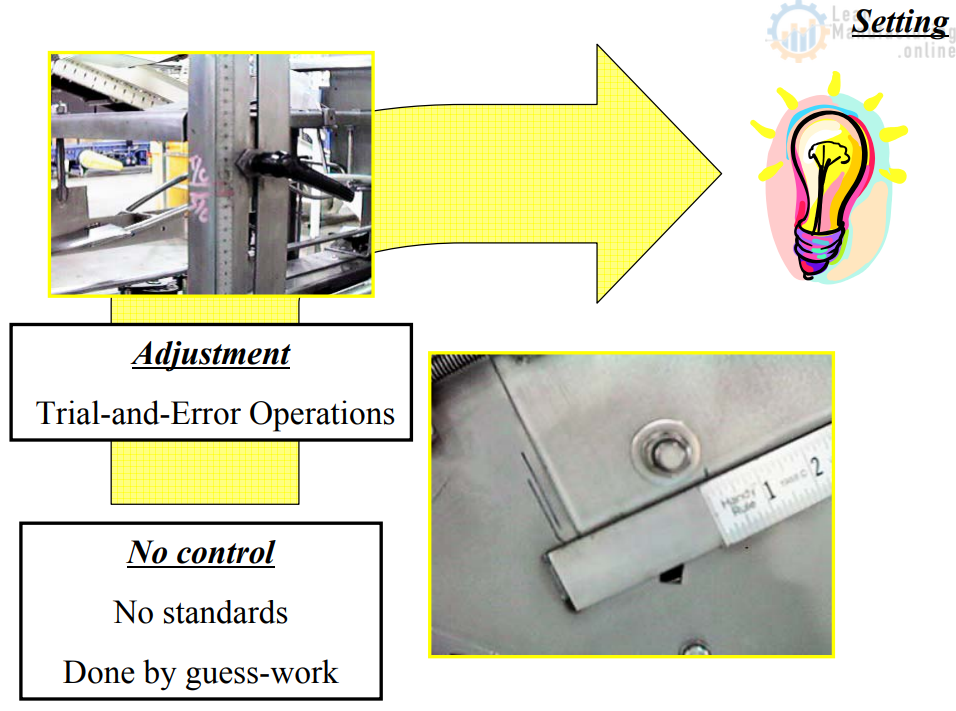

- Adjustment;

- Trial-and-error operations to meet with the quality range of products includes measuring & adjusting.

- Preparation;

- RFT (Right First Time) Changeover means to minimize adjustment operations during changeover operations

- Improve adjustment operations to controlled setups.

- The structure of Changeover operations

Basic Ideas from SMED

- SMED (Single Minute Exchange Die) is the improvement program to reduce Changeover time at a stamping (press machine) shop in an automobile factories. The target for changeover time is less than “10 minutes”, so which is well known as “single minutes exchange die”.

- The basic idea from SMED is to categorize every operations into “an internal operation”and “an external operation”.

An internal operation is an operation during machine stopping, an external operation is an operation during machine running.

The Basic steps at SMED

Basic Rule – Improve Internal changeover operations to External operations.

Approach:

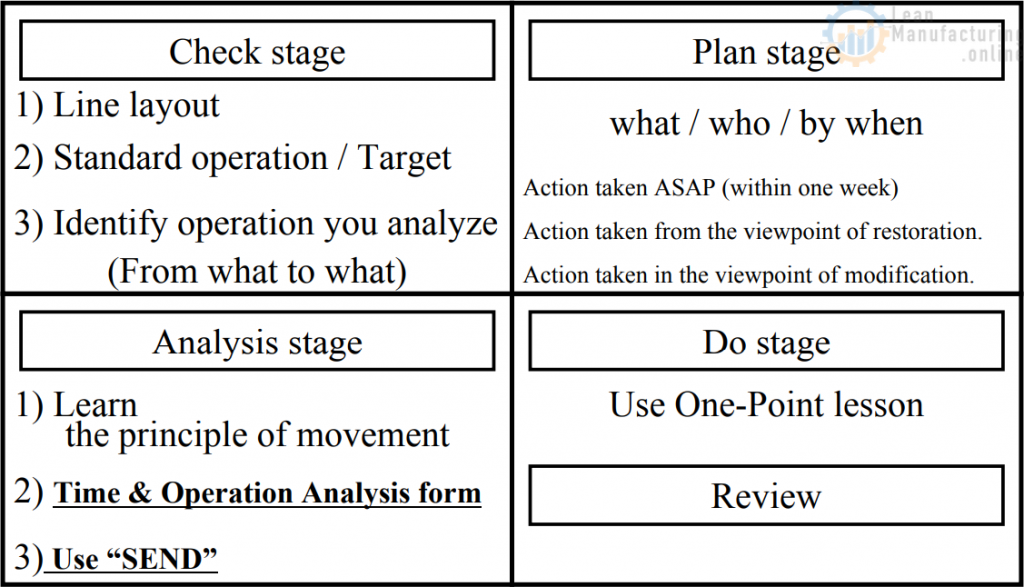

- Observe changeover operations at “GEM BA” (Actual place / On site)

- Improve an internal operation into an external operation.

- Create Time & Operation Analysis Sheet (Worksheet)

- Categorize a type of operations;

- Preparation

- Setup

- Adjustment

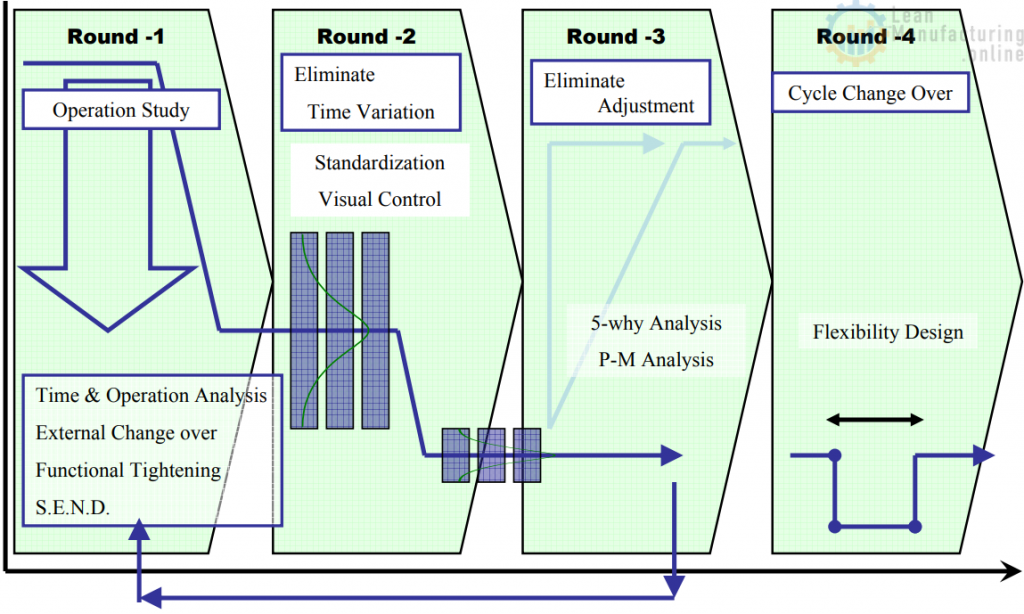

RFT Changeover Improvement Scenario (Model)

Round-1 Changeover Kaizen

- Goal

- Reduce the changeover time to “single minutes”.

- “Single minutes” means less than 10 minutes for changeover time. Original idea; “Single minutes” Example; Reduce 60 minutes to 9 minutes for changeover time per occurrence.

- Understand & use the basic ideas from “SMED”.

SMED; Single Minutes Exchange Die.

- Reduce the changeover time to “single minutes”.

- Key learning

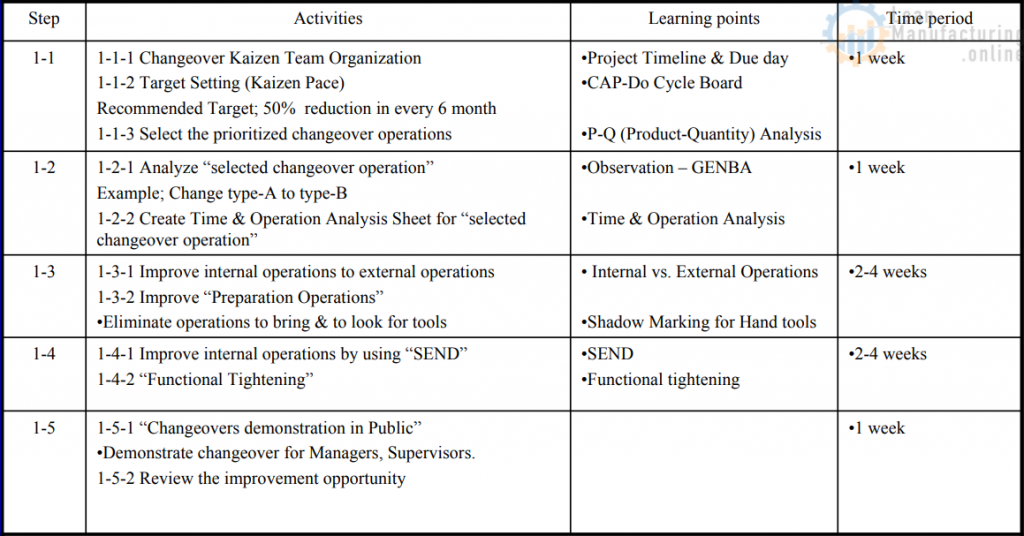

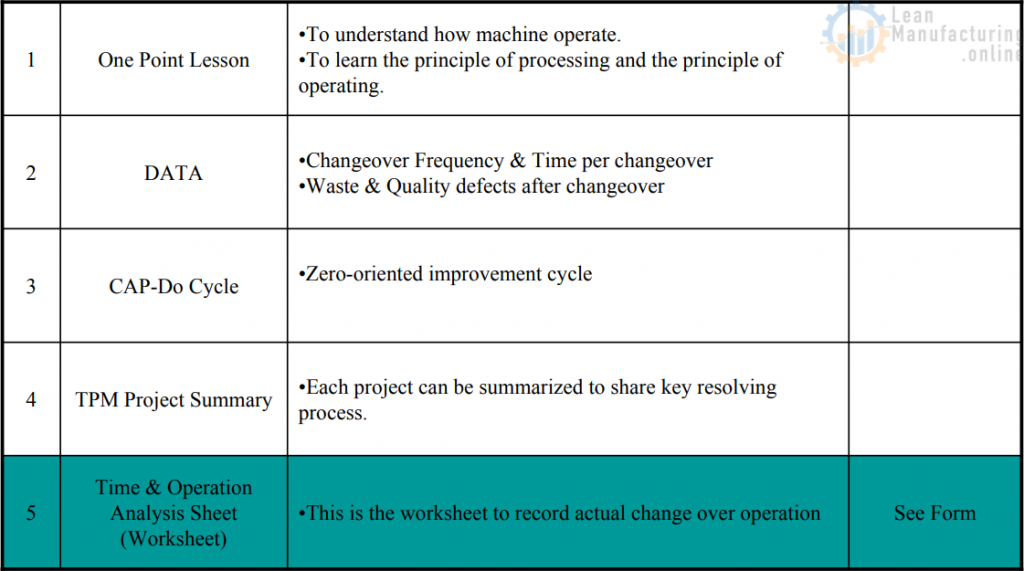

1) Time & Operation Analysis Sheet (Worksheet)

2) Improve internal changeovers to the external ones.

3) Functional Tightening

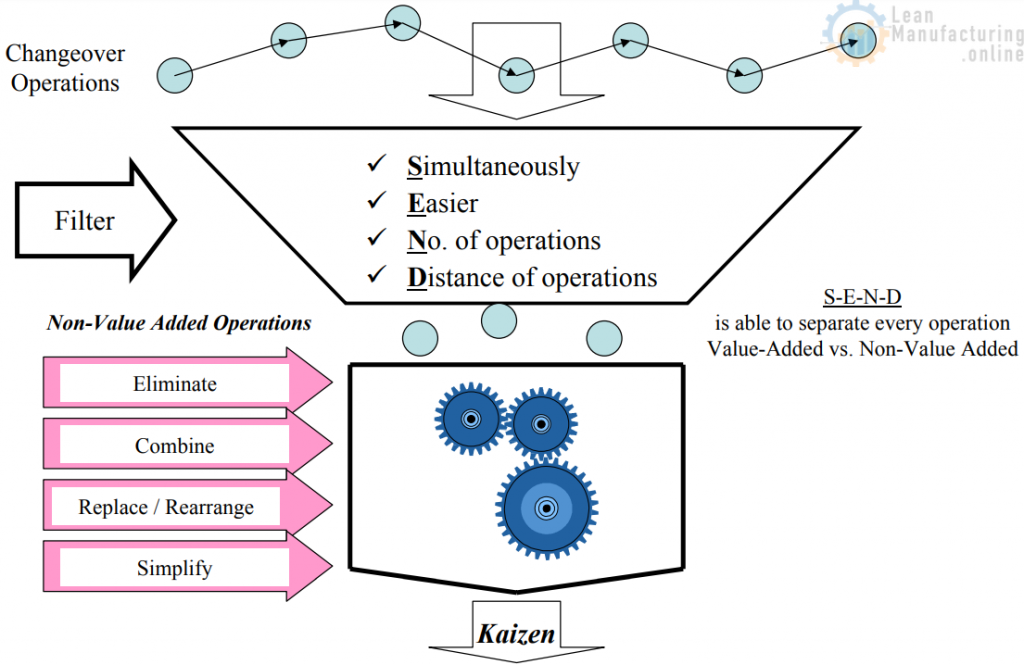

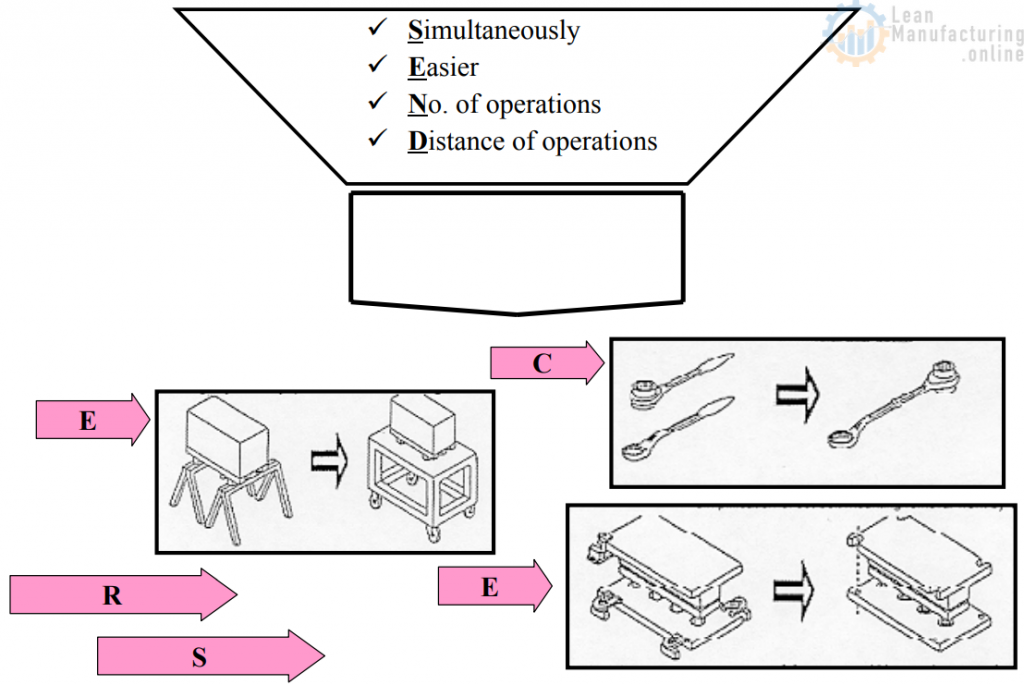

4) “SEND” (Changeover Kaizen Steps)

SMED Format templates are available here

Time & Operation Analysis Form (Worksheet)

- The worksheet – Time & Operation Analysis Sheet (Worksheet) – is to record how long

each internal operation takes and categorize types of operation for preparation, setup

and adjustment. - Identify improvement (Kaizen) opportunity at each step.

Ex. Rotate a screw in 10 times, Kaizen idea is to eliminate or reduce the number of

times.

Round-1 Changeover Kaizen Steps

CAP-Do Cycle Board for Changeover Kaizen

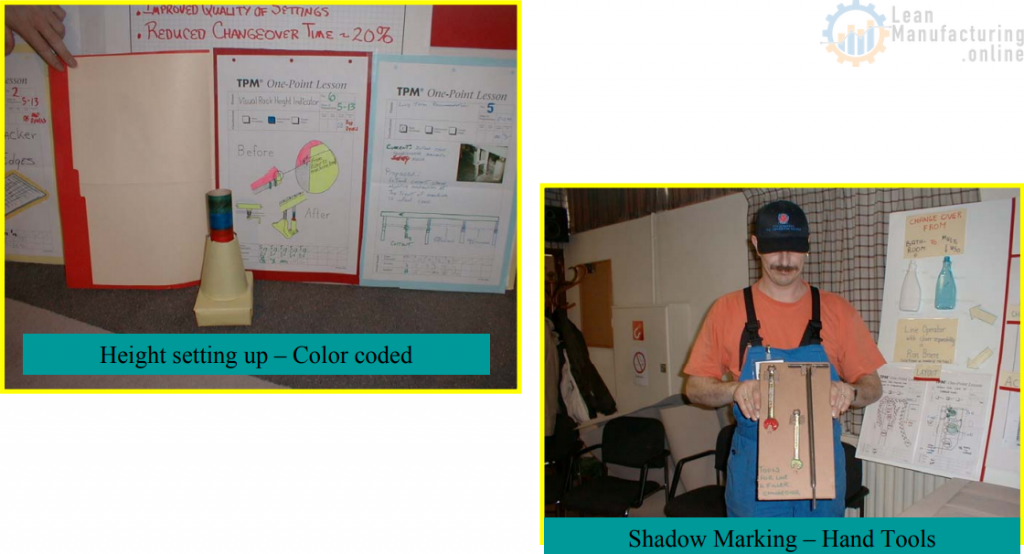

Effective Tools for Changeover time reduction

Visual controls

S-E-N-D Kaizen Filter

SMED Format templates are available here

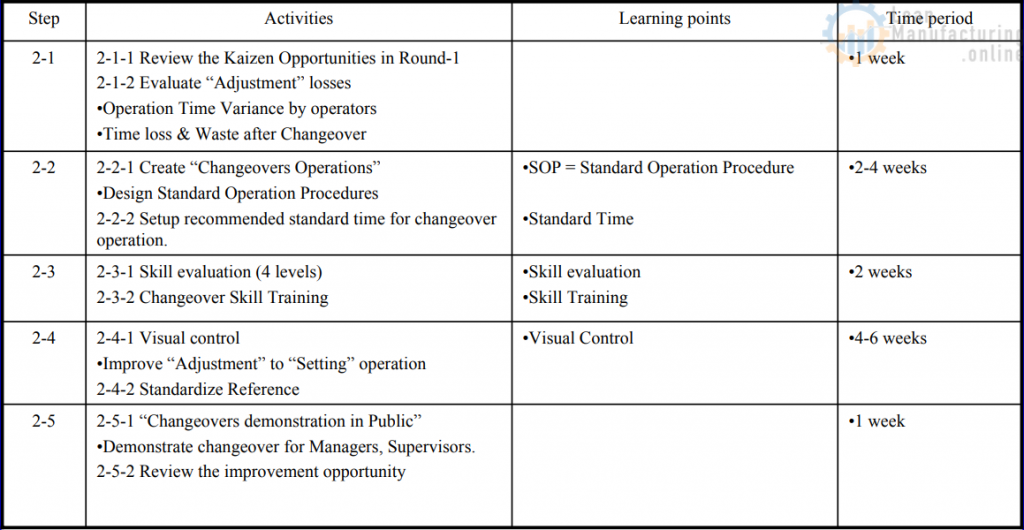

Round-2 Changeover Kaizen Steps

Example of Adjustment

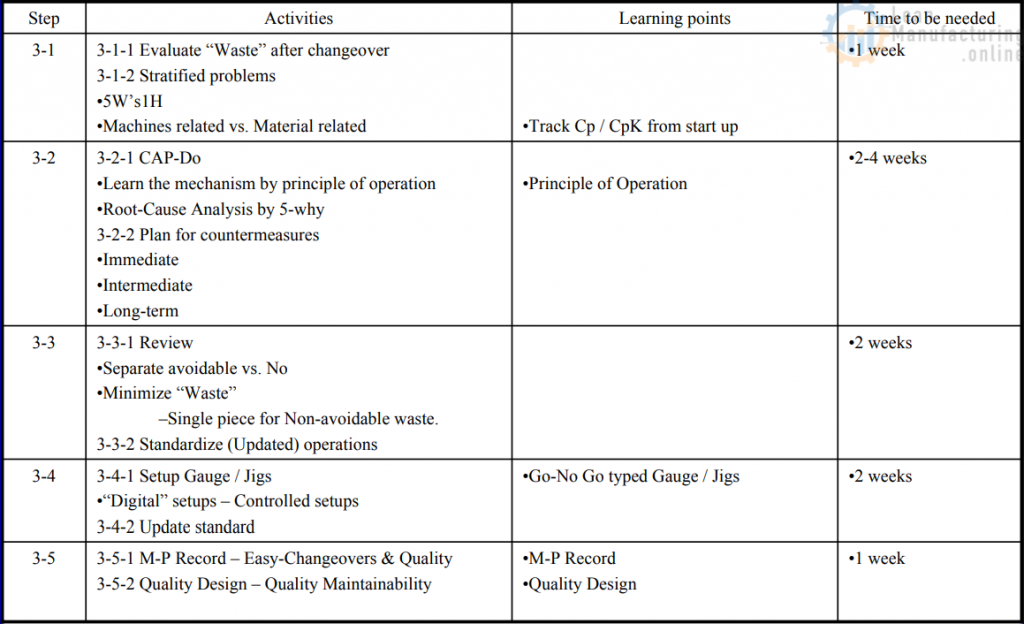

Round-3 Changeover Kaizen Steps

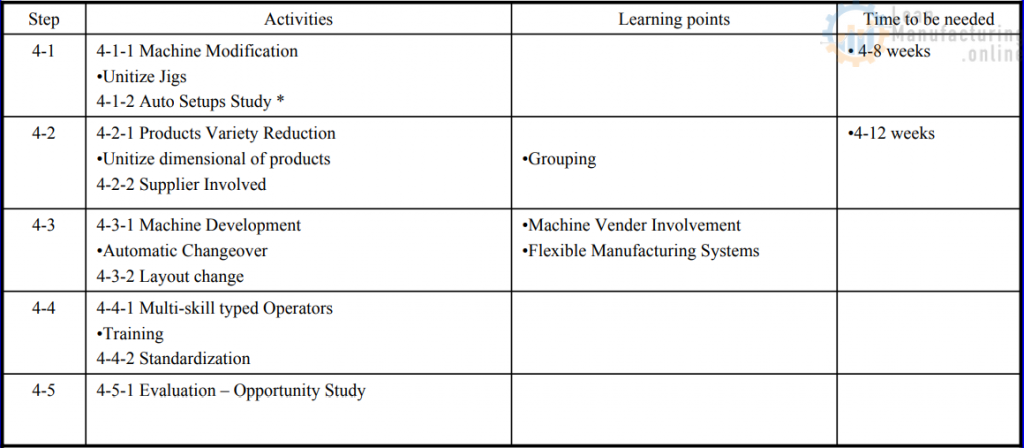

Round-4 Changeover Kaizen Steps

Cycle Changeover

- Less than 3 minutes changeover time

- Changeover time is as long as Cycle time

SMED Format templates are available here