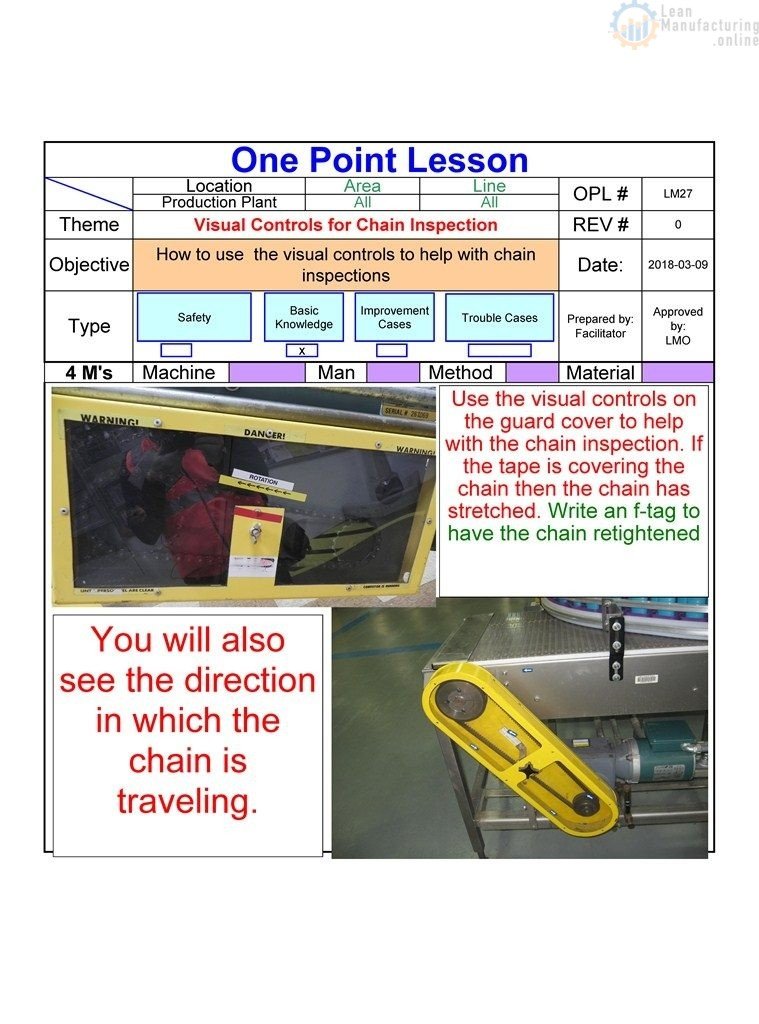

Visual Controls are very useful tools for a quick inspection to determine the condition of assembly to avoid or reduce downtime. One Point Lesson below gives examples of accessible chain and timing belt drive inspections.

January 31, 2026

0 1,082

Six Sigma vs Lean Six Sigma: A Practical Guide

December 27, 2025

0 2,177

How to Improve Manufacturing Processes with the RIVET Method

Artificial Intelligence

Continuous Improvement

Lean

Lean Manufacturing

Lean Six Sigma

Productivity

Safety

TPM

World Class Manufacturing

November 19, 2025

0 2,344

Gemba Walk GPT: The Smartest Way to Turn Observations Into Real Improvement

November 16, 2025

0 2,680

How to Create a Step-by-Step Reveal Animation in PowerPoint

Book reviews

Continuous Improvement

Leadership and Continuous Improvement

Lean Manufacturing

Lean Six Sigma

October 4, 2025

0 3,871

Explore the Best Free Online Libraries in 2025

October 3, 2025

0 3,723

TPM Master Plan: The Roadmap to World-Class Manufacturing

5S

Autonomous Maintenance

Early Equipment Management

Education and Training

Focused Improvement

Manufacturing Support

Planned Maintenance

Quality

Safety, Health and Environment

TPM

World Class Manufacturing

January 31, 2023

0 6,864

TPM Pillar Self Assessment

April 12, 2022

0 7,451

Detailed Autonomous Maintenance (AM) Master Plan. Steps 1 – 5

5S

Autonomous Maintenance

Early Equipment Management

Education and Training

Manufacturing Support

Planned Maintenance

Quality

Safety, Health and Environment

World Class Manufacturing

March 1, 2022

0 2,060

Example of Food Manufacturing site review

Autonomous Maintenance

Focused Improvement

Planned Maintenance

Quality

Safety, Health and Environment

TPM

TPM Introduction

Training

World Class Manufacturing

February 15, 2022

0 6,956

The 3 Tools of TPM

December 25, 2021

0 2,063

How to improve the support for Autonomous Maintenance (AM) teams

Most Popular

4M Analysis Process

The purpose of this procedure is to define the steps to do a 4M …