1. QA vs QC

QA: Ensuring product/service quality through planned activities.

QC: Verifying adherence to quality standards.

2. Audit vs Inspection

Audit: Systematic evaluation against set criteria.

Inspection: Checking conformance to requirements.

3. Defect vs Defective

Defect: Non-conformance causing customer dissatisfaction.

Defective: A unit with one or more defects.

4. DPMO vs PPM

DPMO: Defects per million opportunities.

PPM: Number of defective parts per million produced.

5. Sample vs Population

Sample: Subset of a population.

Population: Total group of interest.

6. COO vs COPO

COO: All costs linked to product/service quality.

COPO: Costs arising from defects and nonconformities.

7. Rework vs Repair

Rework: Making a non-conforming product meet requirements.

Repair: Making it acceptable for intended use.

8. Document vs Record

Document: Plan on how something should be done.

Record: Account of something done.

9. SOP vs WI

SOP: Guide outlining a task’s purpose and process.

WI: Detailed instructions for a task.

10. APQP vs PPAP

APQP: Ensuring new product quality through structured planning.

PPAP: Standardized approval process for new production parts.

11. ISO vs IATF

ISO: NGO that creates international standards.

IATF: Automotive organizations creating quality standards.

12. Instrument vs Equipment

Instrument: Measures machine data.

Equipment: The machine processing the work.

13. Deviation vs Concession

Deviation: Pre-realization deviation permission.

Concession: Using a non-conforming product/service.

14. Corrective vs Preventive Action

Corrective: Addressing occurred nonconformity.

Preventive: Preventing potential nonconformity.

15. Check Sheet vs Check List

Check Sheet: Real-time data collection.

Checklist: Ensuring step completion.

16. Innovation vs Improvement

Innovation: Creating something new.

Improvement: Enhancing existing elements.

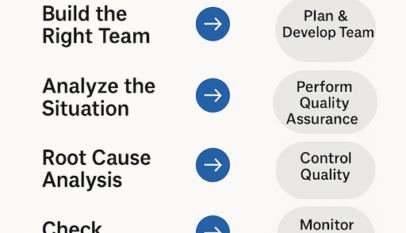

17. CAPA vs RCA

CAPA: Addressing process issues.

RCA: Identifying problem root causes.

18. CpK vs PpK

CpK & PpK: Process capability measures.

19. TPM vs TQM

TPM: Continuous maintenance strategy involving everyone.

TQM: Philosophy of continuous improvement and customer satisfaction.

20. Verification vs Validation

Verification: Checking regulatory compliance.

Validation: Ensuring customer needs are met.

21. Lean vs Six Sigma

Lean: Focus on customer value and flow enhancement.

Six Sigma: Reducing variation using statistics.

22. Value Added vs Non-Value Added

Value Added: Customer sees worth.

Non-Value Added: No additional customer value.

23. Risk vs Opportunity

Risk: Uncertainty’s effect on expected outcomes.

Opportunity: Positive risk side.

24. Process vs Product Audit

Process Audit: Assessing organizational processes.

Product Audit: Assessing individual products.

25. TQM vs QMS

TQM: Philosophy emphasizing continuous improvement.

QMS: Set processes ensuring consistent high-quality products/services.

26. VOC vs VOP

VOC: Customer needs and requirements.

VOP: Process performance communication.

27. Process Stability vs Capability

Stability: Process consistency.

Capability: Meeting specifications.

28. Data vs Information

Data: Raw, unorganized facts.

Information: Contextual, analyzed data.

29. Efficiency vs Effectiveness

Efficiency: Doing the right things.

Effectiveness: Doing things correctly.

30. Continuous vs Continual Improvement

Continuous: Uninterrupted enhancement.

Continual: Phased improvement with intervals.