To reach the desired scenario of highly productive equipment and operators who know their equipment well and can manage their work, Autonomous Maintenance is implemented progressively, starting with preparation (Step 0) and proceeding through seven steps.

Aims

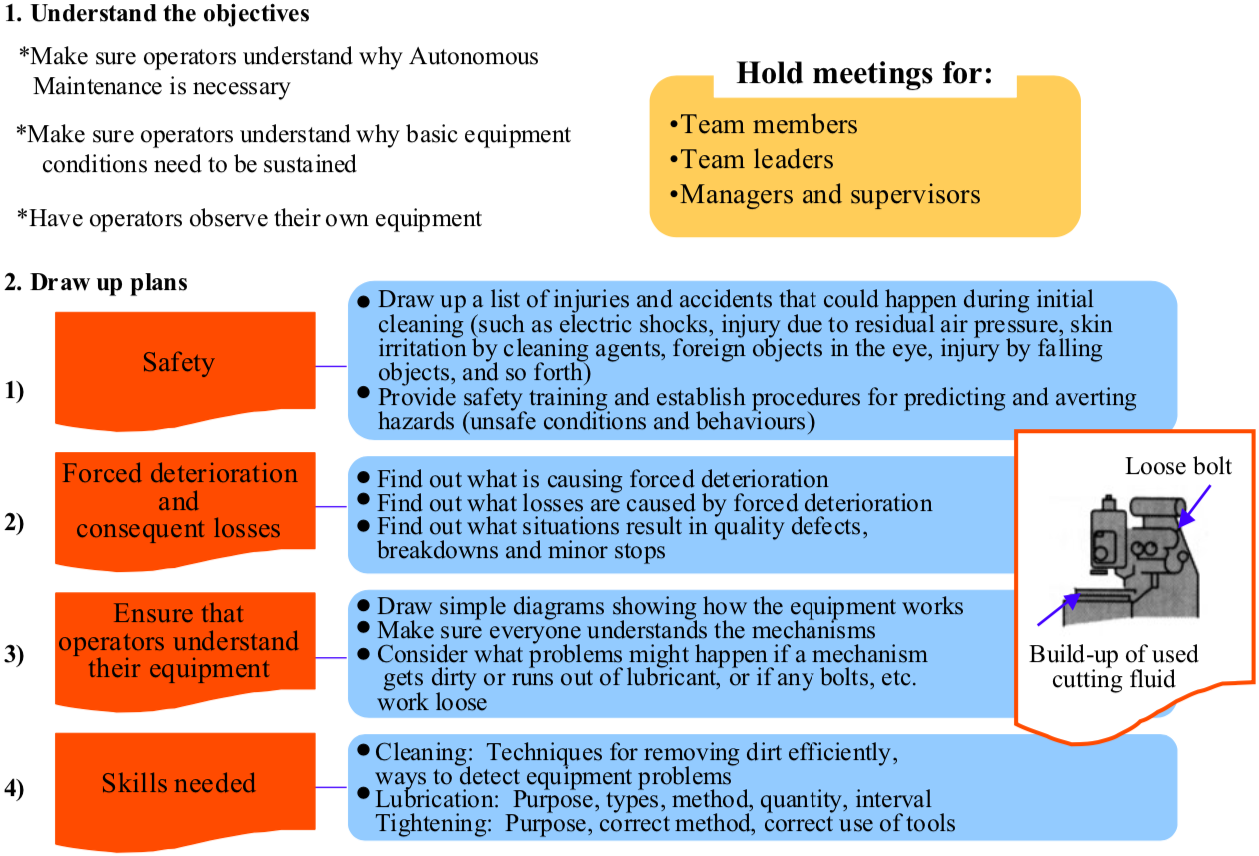

This is an important step, where operators find out for themselves that bad things happen as a result of forced deterioration of equipment. This is how they come to realize why TPM is necessary. Note that action comes first, and motivation grows out of the action process. To become motivated, the operators first have to carry out the prescribed actions. This preparatory step is designed to make the operators think about the causes of forced deterioration, and understand why they are now embarking on Autonomous Maintenance.

(1) Injuries and other mishaps that could occur while implementing Step 0 should be thought through, and thorough safety training given. The unsafe actions and situations that could occur as a result of carrying out the initial cleaning will need to be listed, and a preventive strategy formulated for each.

(2) Have each team discuss the implications of forced deterioration, think about why their equipment has got into the state it is in, and work out what losses result from breakdowns and quality defects caused by forced deterioration.

(3) Have operators draw simple diagrams illustrating the mechanisms used by their equipment. Help them understand how their equipment works and what kinds of problems happen when it gets dirty, learn the names of the parts, and so forth.

AUTONOMOUS MAINTENANCE STEP 0 FORMS can be downloaded here

Next→Autonomous Maintenance. Step 1: Initial Cleaning (Checking through Cleaning)