Aims

In AM Step 2, ways are found to combat sources of dirt, leaks, and so on, and improve accessibility to areas that are hard to clean, lubricate, tighten, or inspect. This is a crucial process that nurtures the seeds of improvement, as operators find ways to improve the situation on their own initiative. It allows them to derive real pleasure from the process of improvement and the results attained, and to share a sense of achievement with their supervisors and fellow team members.

The aim is to enable operators to improve their equipment themselves and give them the confidence to take on more and more advanced improvements.

(1) Eradicating contamination sources

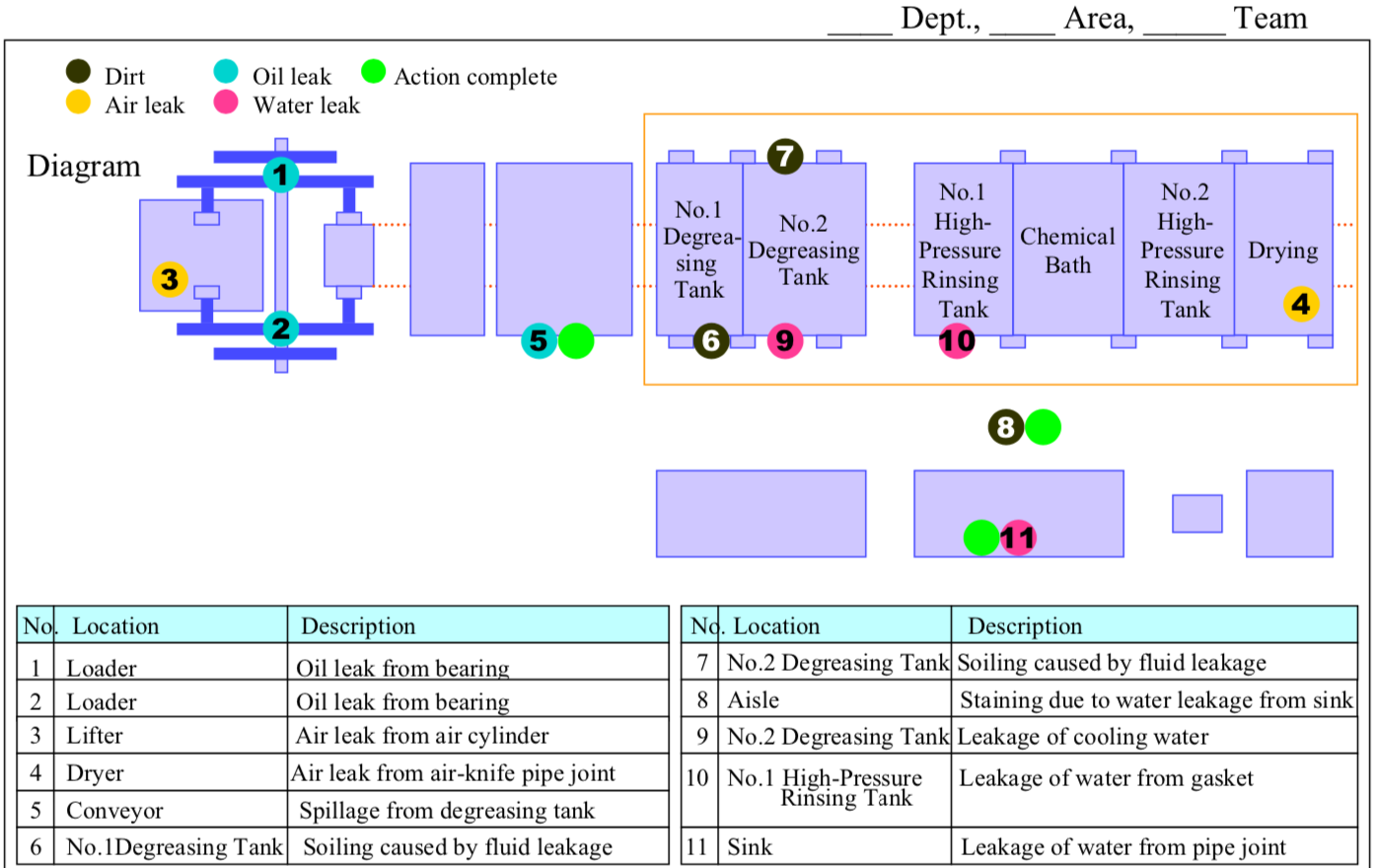

Eradicating contamination sources means identifying sources of dirt or leaks (of air, oil, raw materials, etc.) and then getting rid of them. To do this, a map of sources must be drawn up showing each point where contamination or leakage is occurring, so that they can be addressed systematically, starting with those that have the greatest effect on quality, equipment performance, and the general work environment (see Figure “Map of Contamination Sources”).

Contamination sources are identified in AM Step 1, but in Step 2 they must be painstakingly rooted out. For instance, all sources of oil stain must be eradicated by measures such as preventing leaks in hydraulic pipe joints, or adjusting drip rates if too much lubricating oil is being applied.

Some contamination sources cannot be eliminated completely. For example, the use of cutting fluid, or the generation of swarf or scale, may be unavoidable, and in these cases, practical improvements must be made to minimize the dispersion of these contaminants. Here, the basic approach is to prevent scattering.

(2) Tackling hard-to-access (HTA) areas

Areas that take great time and effort to clean and inspect must be improved to make them more accessible. For example, it is difficult to drain and check FRLs (compressed-air filter/regulator/lubricator sets) located near floor level, so these units should be raised to make the tasks easier to carry out. Similarly, providing an observation window makes it possible to check the state of a V-belt from the outside, without having to remove the cover. Likewise, complex, tangled cable layouts should be eliminated, and cables laid directly on the floor should be raised, make cleaning easier.

Implementation

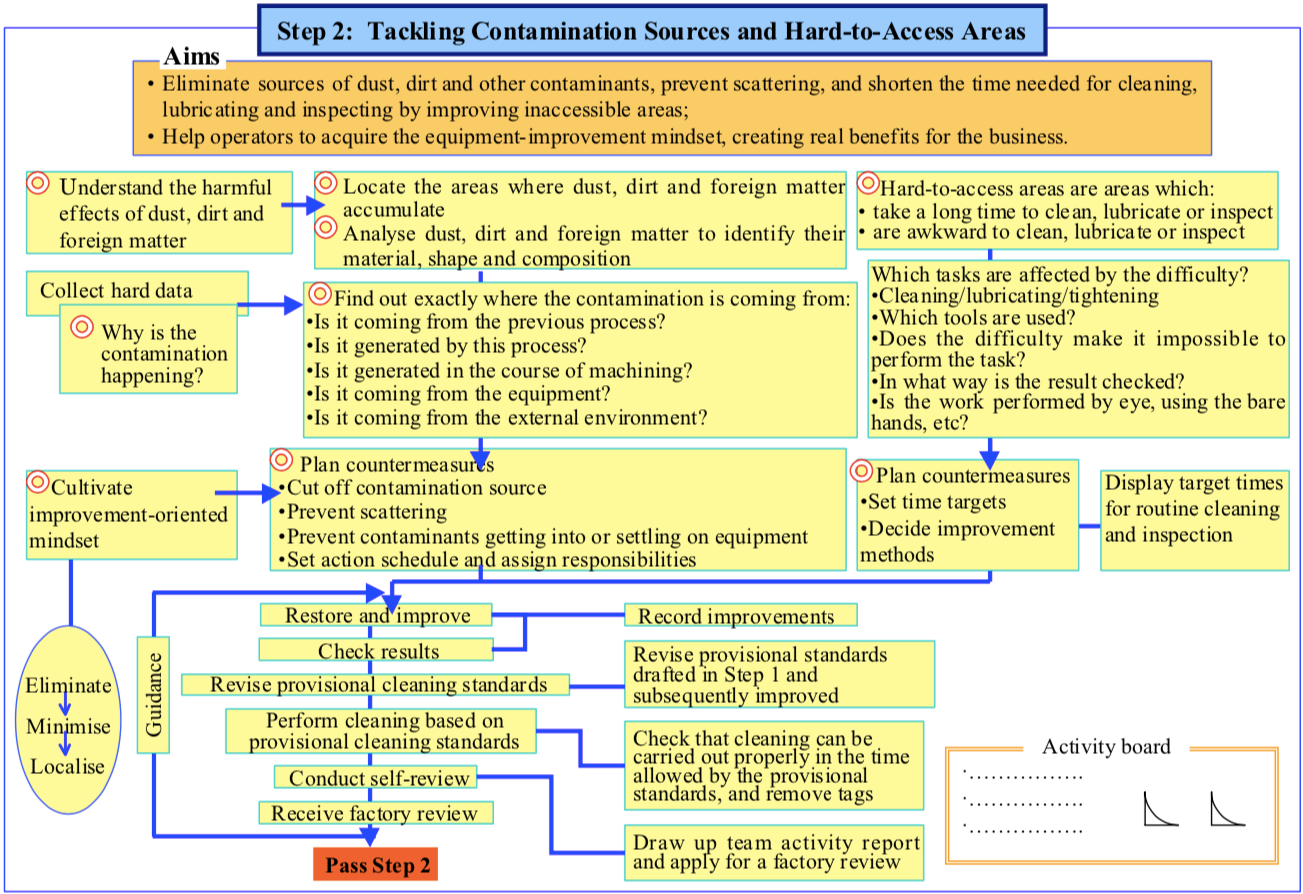

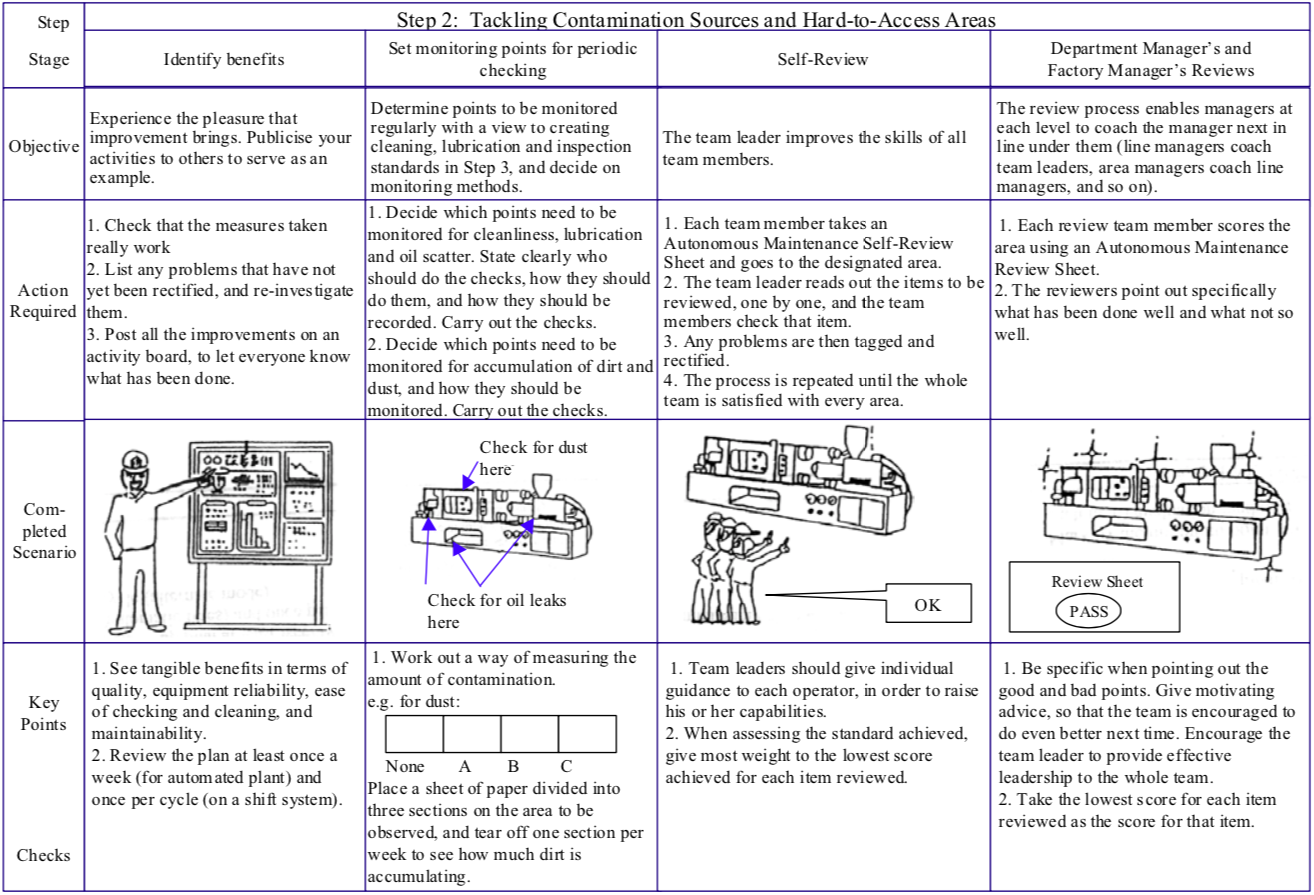

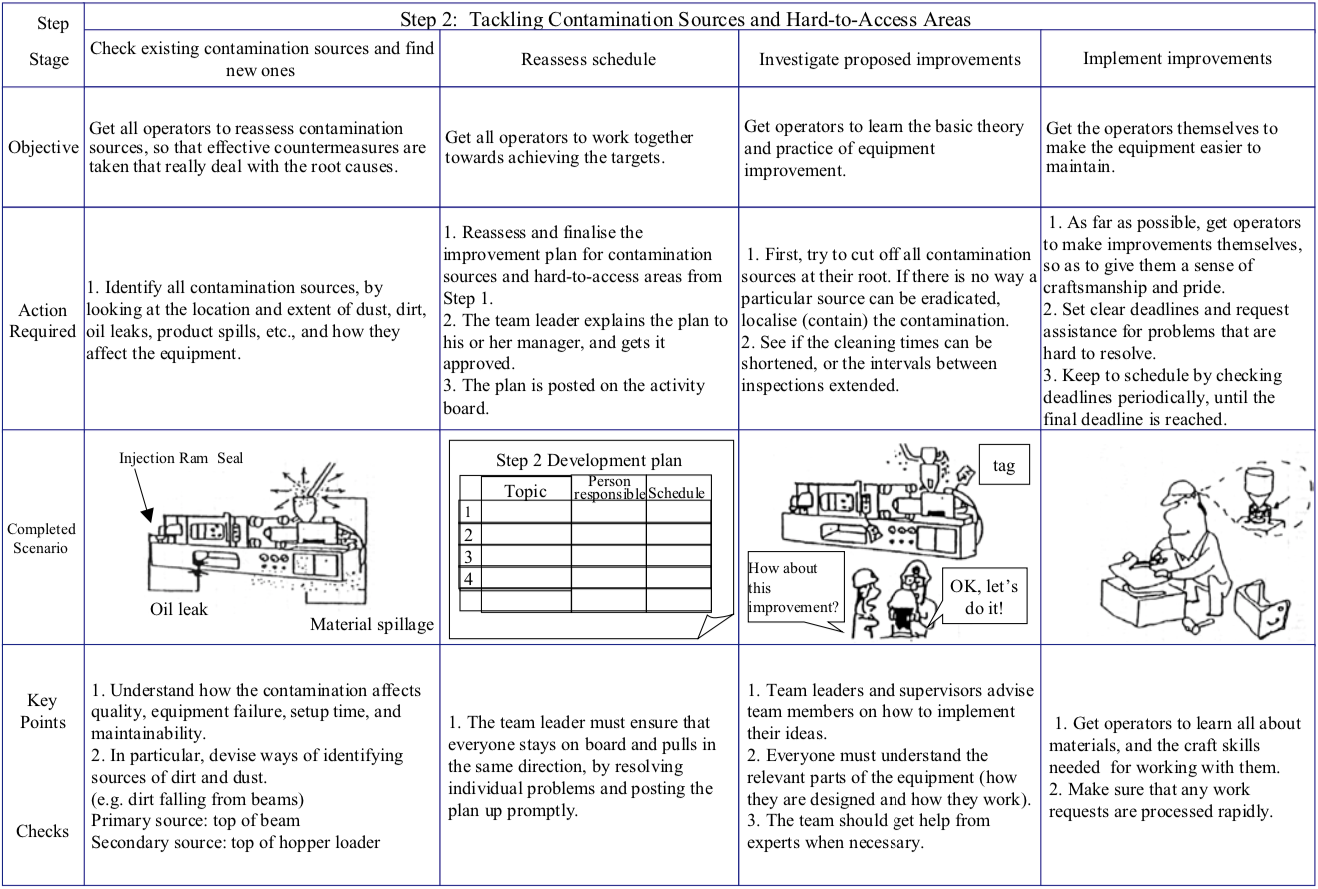

Figure “Workflow for Step 2 (Tackling Contamination Sources and Hard-to-Access Areas)” shows the rollout procedure for Step 2.

Tackling contamination sources is a key part of Step 2. It is worth looking a little further at this subject and how to approach it.

Tackling contamination sources

It involves two key approaches.

(1) Nurture the seeds of improvement

The harder operators work on initial cleaning in Step 1, the less willing they will be to let their lovingly cleaned equipment become dirty again. They will naturally be much more aware of contamination sources and keen to find ways to eradicate them. It is essential to make the most of this opportunity.

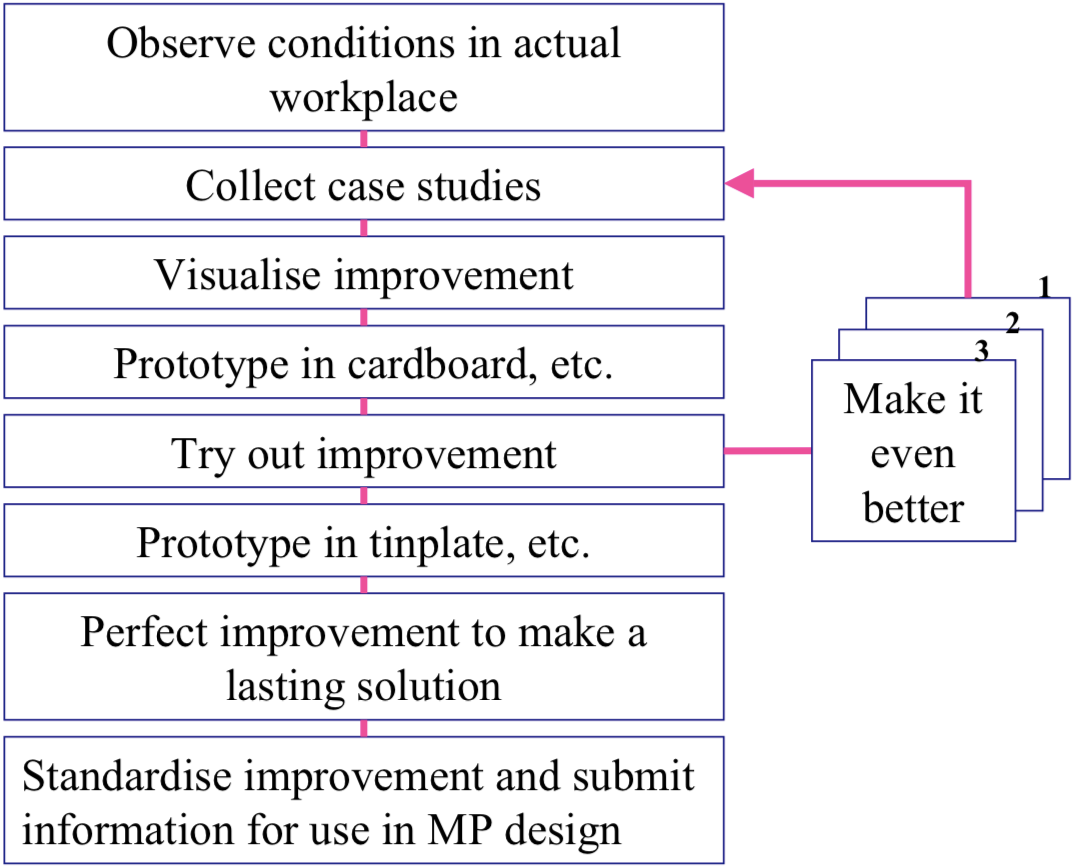

- Rather than spending a lot of money on a few grandiose schemes, it is much better to accumulate larger numbers of smaller, ‘homespun’ improvements. Figure “Procedure for Effecting ‘Homespun’ Improvements” shows a typical approach for making this kind of improvement.

- Establish an effective support system and training facilities. Explain the principles of the processes involved, and teach operators how to spot where the equipment functions can be improved. Show them crafts and techniques they can use to come up with effective improvements. All training should be carefully geared to the operators’ capabilities.

- It is most important for supervisors and managers to boost morale by taking a real interest in these improvements, visiting the workplace regularly to see them for themselves.

(2) Create provisional standards for cleaning and lubrication, based on improvement case studies

Figure “Workflow for Step 2 (Tackling Contamination Sources and Hard-to-Access Areas)” shows the general approach for this, and Figure ” and (2) gives further details.

Next→Autonomous Maintenance. Step 3: Provisional Autonomous Maintenance Standards