Aims

In Autonomous Maintenance Steps 1 to 3, the emphasis is on eliminating forced deterioration and sustaining basic conditions. Operators search out and eliminate equipment abnormalities, institute countermeasures against contamination sources and hard-to-access areas, and develop provisional cleaning, checking, and lubricating standards. Thanks to these activities, they become increasingly able to recognize abnormalities and stop forced deterioration, as well as acquiring an improvement-oriented mindset and learning how to actually make improvements.

While Steps 1 to 3 focus on detecting abnormalities using the five senses, Step 4 (General Inspection) takes this further. It aims to give operators a thorough understanding of the functions and structure of their equipment and develop their ability to perform routine maintenance backed up by relevant logic and knowledge.

When checking equipment, it is very important to pay close attention to minor abnormalities that could lead to breakdowns, quality problems, and other chronic losses, identifying them precisely and taking effective action to eliminate them. To be able to do this, operators need to use the process of Step 4 to learn how to measure deterioration and predict when breakdowns and quality defects are likely to happen.

The equipment aspect

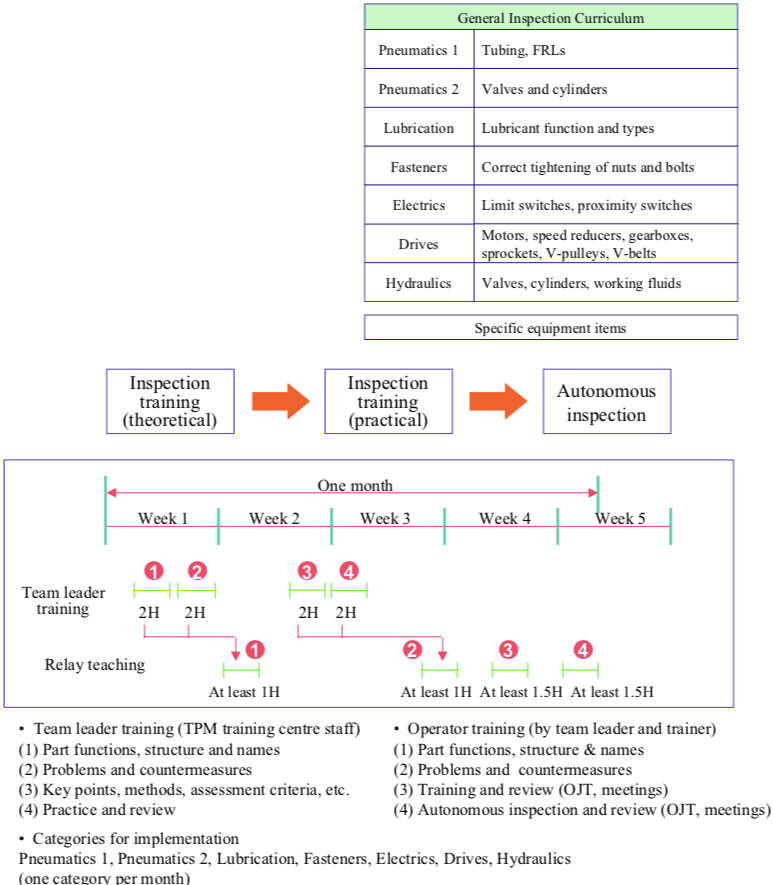

The first step in General Inspection is to establish the appropriate categories (fasteners, lubrication, pneumatics, hydraulics, drives, electrics, and so on). The next is to use the relay teaching method, one category at a time, to teach operators the structure and functions of their equipment, how to check it, and what criteria to use to assess how far it has deteriorated.

Having learned about a category, the operators use their knowledge to check their equipment, restore it, and make improvements. At the same time, they introduce visual controls and improve hard-to-check areas in order to make the checking easier and more efficient. They then incorporate their findings into standards for that category that will enable them to keep the equipment in its restored condition through a simple daily maintenance routine. They repeat this process until they have completed all the categories.

The human aspect

The aim of General Inspection training is to develop operators who are able to check their equipment effectively, recognize when parts have deteriorated or something is going wrong, and perform easy maintenance tasks.

Through training and hands-on experience, General Inspection lays the groundwork for developing operators who are thoroughly conversant with their equipment. Their self-management skills progressively improve as they proceed through the categories one by one, spending two to three months on each.

Guidance and support

The support staff will need to prepare General Inspection manuals and training materials, use these to carry out General Inspection training, teach the operators about visual controls and how to improve inaccessible areas, and teach them how to collect, collate, analyze and utilize the data they obtain from checking their machines.

Implementation

If operators are to know and understand their equipment properly, they must learn all about its common elements and understand the basic functions of the units it is composed of. In AM Step 4, operators receive basic training in areas such as mechanical elements, lubrication systems, pneumatics, hydraulics, electrics, drive systems, equipment safety, and process conditions, and by applying this knowledge when inspecting the equipment, they become able to spot even the smallest defects.

The key points in this process are as follows:

- Team leaders learn about the equipment’s basic mechanisms and functions.

- They pass on this knowledge to their teams.

- The operators use what they have learned to discover problems in the workplace.

- Visual controls are introduced wherever they can be.

Figure “Workflow for Step 4 (General Inspection)” shows the basic workflow for this step.

Step 4 sub-steps

(1) The requirements of the Step 4 training program will depend on the following:

- What the operators need to know about running their equipment correctly – setting conditions, operating, doing changeovers, etc.

- What checks the operators need to do.

The above issues must be studied in light of the equipment’s specification and the situation regarding problems such as breakdowns and quality defects. However, operators should at the very least learn about the basic elements that their machines are composed of (e.g. fasteners, lubrication, pneumatics, hydraulics, drives, electrics, and controls).

Note: There is no point in getting operators to dismantle equipment they have no need to check or adjust, or teaching them about the structure and principles of such equipment. The training curriculum must be carefully selected to enable operators to obtain a deep understanding of the checking and adjustment tasks they need to do, and the training materials should be broken down into simple, easily-grasped units. Factories sometimes put together over-complicated materials containing lots of difficult formulae to impress visitors, but materials like these should not be used for operators’ practical training. These points should be borne in mind when choosing the materials for General inspection training.

(2) Preparing Know-Why sheets

The most important materials that must be prepared when getting ready for General Inspection training are:

- General Inspection Checksheets

- General Inspection manuals

To get these ready and ensure that everyone understands their machines, simple Know-Why sheets must be prepared that summarise the principles of operation and abnormal conditions of the machines that are to be taught, and that explains what is wrong with these abnormal conditions and what kinds of checks and inspections must be carried out to keep the machines in good condition (see Figure “Typical Checklist and ‘Know-Why’ Explanation for Filter”).

(3) Preparation of General Inspection Training Materials

1 Inspection checksheets

Start by surveying existing maintenance records on quality defects, breakdowns, minor stops, and other problems in order to identify in detail all the five-senses checks that it is considered necessary for the operators to do. Compile the results in the form of checksheets.

Procedure for preparing Inspection Checksheets

- Copy out the checkpoints from the Know-Why sheet.

- Based on the Know-Why sheet, consider what standards are required in order to keep the equipment in good condition.

- Try writing in the checking procedure and standards.

- Think what would need to be done if the device being checked were found to fall short of the standard.

- Try describing what would need to be done, but remember there is no point in giving an instruction that the operators could not follow with their current level of knowledge and skill. They should also not be required to take precise measurements if they do not have the necessary instruments or skills.

- It is a good idea to include photographs or cartoons if these will help the operators.

Key points to remember when preparing checksheets:

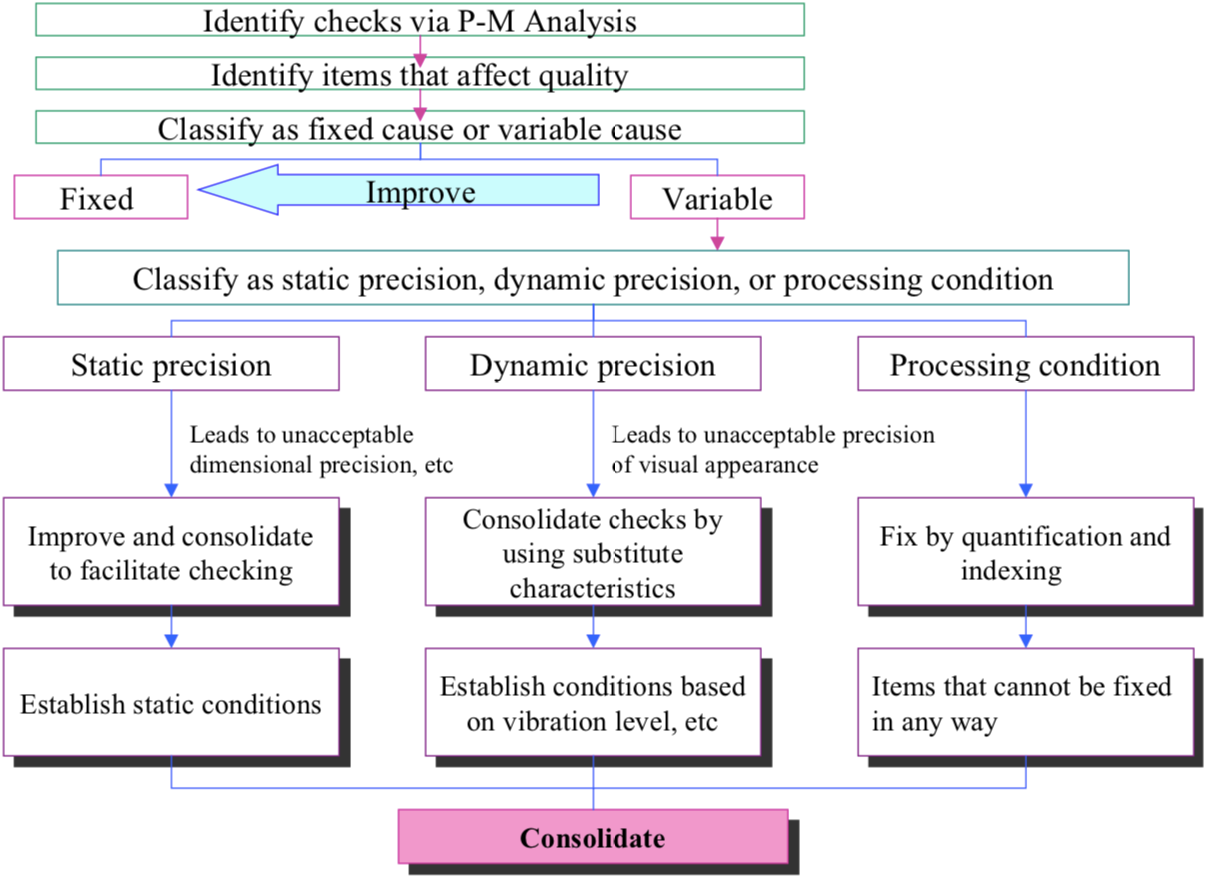

The “level of variability” must be determined when setting the frequency with which the checks must be performed. There are three “levels of variability”, as explained below.

- Variable (to be checked daily). An item termed ‘variable’ is likely to vary on a daily basis and therefore must be checked daily. Operators should check and adjust such items without fail every time they start work or at another suitable time.

- Semi-fixed (to be checked monthly or as specified in the maintenance calendar). An item termed semi-fixed is not likely to vary during normal operation but must still be checked and adjusted monthly or at every changeover.

- Fixed (permanent improvement completed). An item termed ‘fixed’ does not vary at all during normal operation.

The level of variability of the items to be checked and adjusted will change as the operators’ skills improve, Effective Maintenance makes progress, and deeper Focused Improvements are carried out. In the early stages of Step 4, almost all of the items will be variable, but they will gradually progress towards semi-fixed or fixed as the operators and maintenance engineers become more and more skilled.

General Inspection checksheets are created by combining all the individual checksheets into a single sheet for each machine (see Figure “A General Inspection Checksheet”).

2 Inspection manuals

Think about what the operators need to learn in order to be able to check their machines effectively, and compile the information into manuals designed for the team leaders to use. These manuals must clearly explain the equipment’s basic structure and functions, the names and functions of its components, the criteria against which it should be checked, how it should be checked, what happens when its functions deteriorate, what the causes of any such deterioration are, and what should be done about those causes.

Furthermore, manuals alone are not enough to teach these details sufficiently; it is also important to devise effective training aids such as cutaway models, easy-to-understand wall charts, and photographs showing actual examples of how the equipment can deteriorate.

Procedure for creating inspection manuals:

- Copy out the checkpoints from the Know-Why sheet.

- Copy out the checking procedure, and the standards for deciding whether what is being checked is in acceptable condition or not, from the Know-Why sheet.

- Based on the Know-Why sheet, write out the proper steps to be taken if a problem is discovered.

- Try describing the inspection methods required and any tips and tricks for performing the inspection (the Know-How), but remember there is no point in giving an instruction that the operators could not follow with their current level of knowledge and skill. They should also not be required to take precise measurements if they do not have the necessary instruments or skills.

- It is a good idea to include photographs or cartoons if these will help the operators.

- Have the operators see whether they can actually perform the necessary checks and adjustments by using the manuals.

Key points to remember when preparing manuals:

The manuals do not have to be works of art. It is better to have one simple manual per machine. Bulky, textbook-type manuals are not suitable for training operators. They should be easy to understand by the people on the shop floor, capable of being corrected on the spot if found to be ambiguous in any way, and gone over thoroughly to ensure that every operator can use them to perform the necessary checks and adjustments (see Figure “Inspection Manual for Individual Part”).

Step 4 templates can be purchased here

Planning the Schedule for General Inspection training

(1) Time required for General Inspection

Step 4 requires quite a long time (normally 12 to 15 months) and many labour hours to complete. Team leaders will need 8 to 16 hours of training for each category, while operators will need 4 to 8. Checking the equipment will take 20 to 30 hours depending on how big or complicated it is. Figure “General Inspection Curriculum and Timetable” shows an example of a General Inspection curriculum and timetable.

(2) Proposing the schedule for General Inspection training

The General Inspection training schedule must be decided together with the production department’s managers. The maintenance department cannot determine the schedule on its own, because it necessitates finding time for the operators to receive their training, deciding how overtime is to be used, acquiring training facilities, coordinating team leaders’ work schedules, and estimating and budgeting for the cost of the training.

(3) Pattern for carrying out General Inspection training

The training for General Inspection should not be carried out all at once. Each category is taught, then the checks pertaining to that category are performed, and then the training for the next category is modified in the light of the results. The training should be basically practical and carried out in the workplace; trainees should not be kept cooped up in a classroom for long sessions until they get bored.

(4) The importance of relay teaching

Relay teaching is the most effective way of conducting Step 4 training. In this method, the team leaders are trained by the maintenance staff and then become trainers themselves, passing on what they have learned to their team members.

a The maintenance department begins by explaining things to the team leaders

b Teach the key points of horizontal replication

c Review each machine and revise the manuals

d Team leaders collect drawings, information on past problems, etc., and use these for the training

e These are then applied to the actual machines by the team leaders and operators

f Each team’s experiences are passed on to other teams by having meetings

g The operators perform General Inspection

h Efforts are made to monitor and raise the levels of operators’ knowledge and skill

Making learning more fun

To maximize the training’s effectiveness, it is important to try and make it as interesting and enjoyable as possible. Good ways of doing this include disassembling simple units, building the training materials around actual workplace problems, and introducing some friendly competition to make the training feel more like a game (for example, splitting the team up and seeing who can find the most defects within a given time).

Performing General Inspection training

The General Inspection training planned within the preparation phase described above is now carried out.

Performing General Inspection

Before carrying out General Inspection at Step 4, the provisional standards prepared during Steps 1-3 should be revised, removing every unnecessary item (and every item that could be made unnecessary through improvement), and including any items that are necessary but have been overlooked. If this is not done thoroughly, and the number of items to be checked and the time is taken to perform the checks is not reduced, the operators may not have enough time to do all the checks and meet their production targets. Likewise, if omissions are not corrected, breakdowns will occur and the same situation will arise.

(1) Revising the cleaning, lubricating and checking standards from Steps 1-3

Zero failures and quality defects

Any necessary checks omitted from the cleaning, checking, and lubricating standards must be identified. This means studying historical records of equipment failures, defects, and inspection errors, and looking at what has been done to prevent them from recurring, to see if anything has been overlooked.

Efficient cleaning, checking, and lubricating

Ways should be found to reduce the number of checks specified in the cleaning, checking, and lubricating standards. Duplicated tasks should be eliminated, and checks should be combined with other work (enabling operators to check the equipment at the same time as cleaning or lubricating it, for example).

Balanced cleaning, checking, and lubricating

The cleaning, checking, and lubricating tasks are often concentrated at the start of the week. The workload should be balanced by reviewing the frequency of the checks, the time they require, and the order they are done in.

Visual management

The visual management aspect of the checks should also be reviewed, along the following lines:

- Is it easy to see where the check needs to be done?

- Is the check itself easy to perform?

- Is it immediately apparent if something is wrong?

(2) Procedure for performing General Inspection

- When performing General Inspection, ensure that responsibilities are clearly specified. The ultimate aim of Step 4 is to improve the reliability and maintainability of every item of equipment the teams are in charge of by having them check it comprehensively in all of the General Inspection categories and reverse any deterioration they find. Using the knowledge they have acquired through the General Inspection training program, the teams inspect all their equipment thoroughly, hold regular meetings, deal with any problems they detect, and keep on improving their equipment maintainability. The maintenance department’s support in all of this is crucial. It must work even harder than it did in Steps 1 to 3, doing everything in its power to complete any work the teams request promptly, as well as continuing to run its own planned maintenance program.

- After performing a General Inspection of each category, draw up an Autonomous Maintenance Step 4 problem list and formulate proposals for corrective action.

- Restore and improve. As they carry out General Inspection, the teams identify deterioration and come up with ideas for improving hard-to-check areas, dividing the work up among themselves in order to get it done. They must keep on improving both the equipment and the checking methods until all the necessary checks can be completed within the specified time.

Standardizing after each General Inspection category

Provisional daily checking standards should be prepared promptly, either during or immediately after the completion of each General Inspection category. They are still called ‘provisional’ at this stage because the definitive standards are not finalized until Step 5. Standards are usually more difficult to revise once they have been finalized, so it is very important to prepare and check the provisional daily checking standards at Step 4.

Procedure for drawing up provisional daily checking standards

(1) Reduce checking times

The optimal checking times and intervals must be decided by trial and error. Begin by setting a target time for each check as a guideline, and try doing it within the target time. If the target is not met, improve the equipment or the method of doing the check until it is. Likewise, adjust the checking intervals until the most appropriate ones are found, and juggle the responsibilities of the maintenance and the operating departments until the best combination is achieved.

(2) Consolidate checks

The ECRS method used for improving changeovers is also useful for consolidating checks (that is, grouping checks together to reduce their number).

ECRS stands for:

E: eliminate

C: combine

R: replace

S: simplify

(3) Reduce the numbers of checks

The number of items to be checked can be reduced by making variable factors semi-fixed or fixed, as shown on the checksheet given in Figure “Making Variable Factors Semi-Fixed or Fixed”).

(4) Standards

An action standard should be drawn up for each General Inspection category, specifying the checks to be performed, the methods and tools to be used, whether to perform the checks with the equipment stationary or in motion, the assessment criteria, what to do if problems are found, how long each check should take, and how often each check should be done. These standards should be kept up to date by amending them every time an improvement is effected. They should do the following:

(a) Allow all the necessary checks to be done properly within the allocated time

(b) Permit the equipment to be kept in its restored state through daily checking and maintenance by operators, thereby boosting its reliability

(5) Delivering Results

Remember that the aim of Step 4 is to train the operators to discover and eliminate potential problems by actually carrying out General Inspections on their machines. They must develop the theoretical knowledge they acquire into real practical skills through repeated practice, and use these skills to deliver tangible results for the business. To accomplish this, they must conscientiously record all the problems and daily maintenance difficulties they encounter and take effective action to banish them from the workplace.

(6) Checking Inspection Skills

The purpose of conducting a skill check is not to test theoretical knowledge – it is to find out whether people know what parts of their equipment they are supposed to check, how they are supposed to check it, and what they are supposed to be looking for.

1 Team Leader Training and Skill Checks

Team leaders usually receive their training during normal working hours or overtime. The knowledge that they will be tested at the end of their course helps to focus their minds on the training, and achieving a good score in the test is an excellent source of motivation.

2 Relay Teaching and Skill Checks

The purpose of relay teaching is to train the operators to carry out the necessary checks on their machines, and skill tests should be limited to this. Most operators have not had to take an exam for a very long time, and being made to take a test can put them under considerable psychological pressure. Everything should be done to ensure that they pass, and trainers should think very carefully before failing anyone. It is a good idea to let them know beforehand what the test involves, and make sure they are well prepared for it.

3 Skills Management

Test results and completed course units should be displayed on team activity boards in the form of matrices, radar charts, etc., in order to identify areas where further training is required. The team leader or training facilitator should then provide opportunities for operators to receive this training. Operators may need to acquire skills that are more specialized than those normally taught through the Autonomous Maintenance program or are unique to a particular machine or process, so it is important to take stock of the teams’ skills and manage them in the way described.

Step 4 does not require operators to check things precisely using sophisticated measuring instruments; it requires them to perform simple checks and maintenance tasks which they must practice until they have embedded them in their ‘muscle memories’ and can do them rapidly and effectively. They need to perform the checks

using their five senses, assisted by visual controls, as in the following examples:

- Sight: look for rusty or dirty equipment, disconnected or cut wiring, dirty gauges, etc.

- Touch: feel for loose bolts, overheating, wrong torque, vibration, etc.

- Hearing: listen for strange noises, air leaks, fluid leaks, etc.

- Smell: sniff out strange smells due to dirtiness, overheating, fluid leaks, gas leaks, etc.

- Taste: lick something in order to detect odd tastes (rarely used in TPM).

(7) Assessing the benefits of General Inspection

The aim of General Inspection is to train the operators to take a logical approach to the identification of potential problems, based on a sound knowledge of their equipment, to give them a good set of checking skills, and to increase their restoration and improvement ability. This will result in more and more potential problems being identified and solved, which is one measurable benefit of General Inspection.

However, as the number of checks to be performed increases with each new category covered, it will become impossible to complete them all within the required time unless something is simultaneously being done about parts of the equipment that are difficult or time-consuming to check. Visual controls need to be introduced in order to cope with this, and the results can be measured in terms of the increasing efficiency of the inspection routines. If possible, benefits should be expressed in monetary terms so that everyone can understand the impact of the improvements on the profitability of their business. Some suggestions for assessing the benefits of General Inspection are given below.

1 Tangible Benefits

(a) Process results

- Number of potential problems uncovered in each category

- The number of remaining contamination sources and hard-to-access areas improved

- Number of tags attached and removed

- Number of visual controls introduced (time and motion savings, number of misidentifications prevented and mistakes averted)

- The proportion of improvements carried out by own team

- Number of major defects discovered

- Number of improvement-related one-point lessons created

- Number of improvements to hard-to-check locations

- Number of problems that everyone is particularly pleased to have found and solved

(b) Output benefits

- Reduction in cleaning time

- Reduction in checking time in each category

- Reduction in shortstops and breakdowns

2 Intangible Benefits

- Operators can perform the necessary checks simply and quickly, and manage their equipment easily

- Visual management enhances maintainability and ensures that no checks are overlooked

- Operators can affect their own improvements

- Operators can draft their own standards

- Operators can check intelligently, understanding why they are doing it