Module Objectives

- Basic valve safety awareness and technical valve training

- Basic understanding of how different valves operate

- Basic understanding of different valve assembly’s

- What usually happens when a valve leaks or sticks, what to visually inspect, and abnormalities you may encounter

Valve Safety

- Always isolate valve before servicing

- Always remove automatic actuators before servicing valves

- Valve actuators are a source of stored energy

- Do not put fingers or other body parts in an actuated valve

Need for Zero Energy State

- Protects you from unexpected release of all sources of hazardous energy.

- Hazardous energy includes:

- Electrical, Mechanical, Hydraulic

- Pneumatic, Chemical, Thermal

- Potential stored energy

MUST be completed prior to performing maintenance, repair, cleaning.

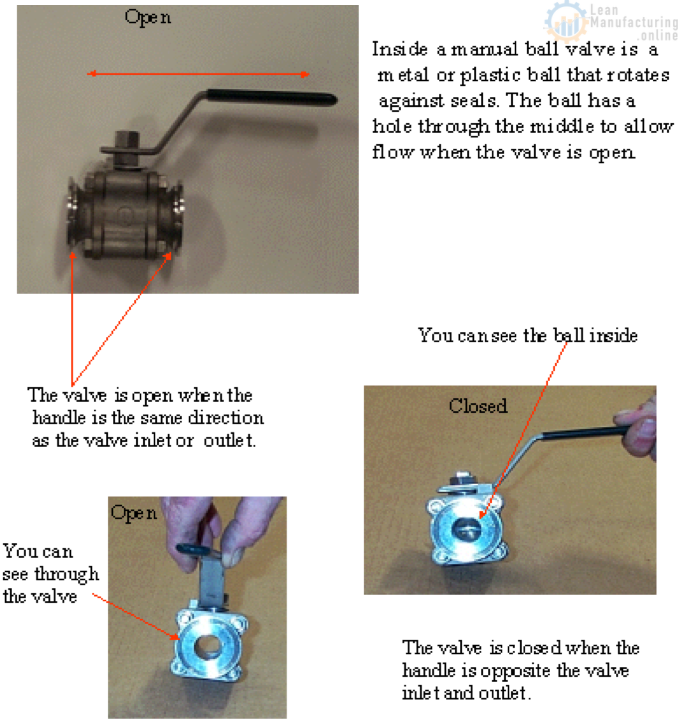

Ball Valves

Butterfly Valves

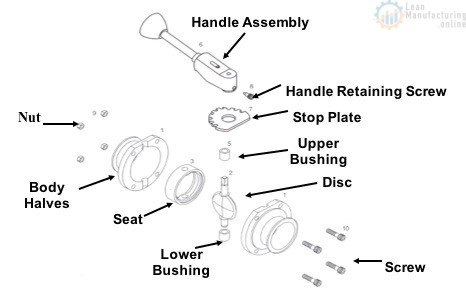

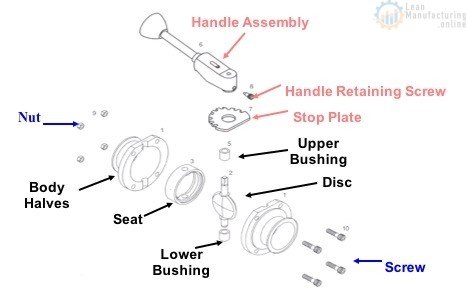

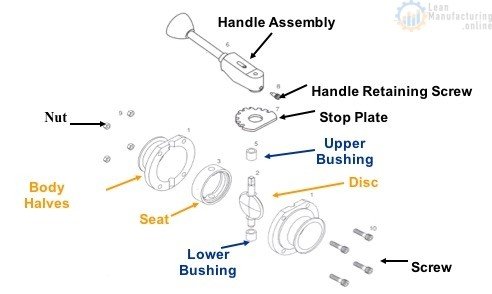

The seat gasket is the most common part that fails in the

manual butterfly valve. It is relatively easy to replace and

the following steps will give a breakdown of how to accomplish

this replacement. First, open the valve and flush and drain the

line in which the valve is located. Remove the valve from the

line by releasing Tri-Clamp connections.

Next, remove the handle retaining screw from the valve stem

and handle. Remove the handle and stop plate from the stem.

Now using box or socket wrenches and an Allen wrench of the

correct size, release and remove the hex nuts and screws that

clamp the body halves together.

Separate the two body halves and remove the seat gasket

and butterfly disc assembly (this will all be one piece until

the bushings are removed).

Now remove the bushings from the upper and lower stem ends.

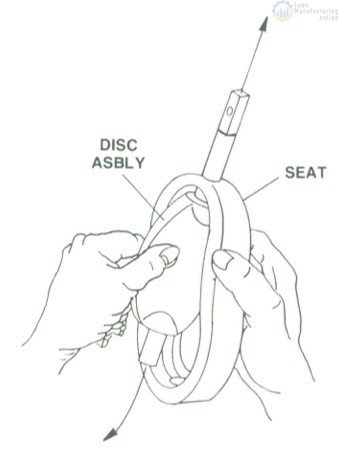

Now, be sure the disc is

in the open position and

squeeze the seat gasket into an ellipse, raise the

butterfly disc and release the lower stem end.

The disc is now ready for removal

Posi-Flate Valves

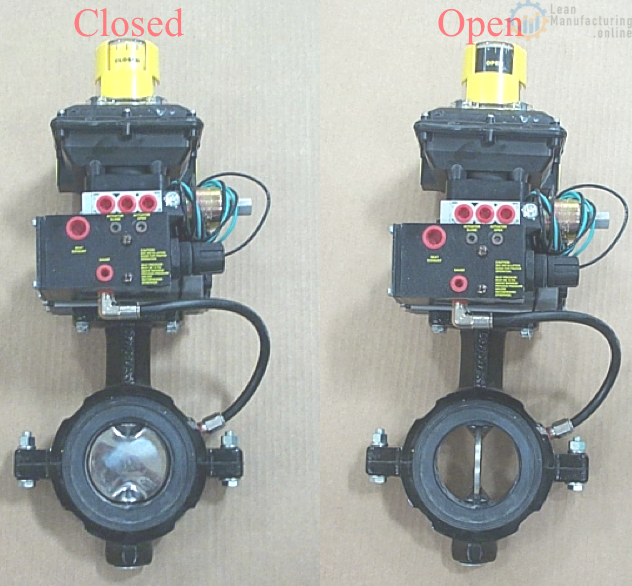

A Posi-Flate valve operates the same as a butterfly valve except,the Posi-Flate is an automatic valve that is air and solenoid operated. The valve also has a controller to inflate and deflate the seat around the butterfly valve.

Disc Check Valves

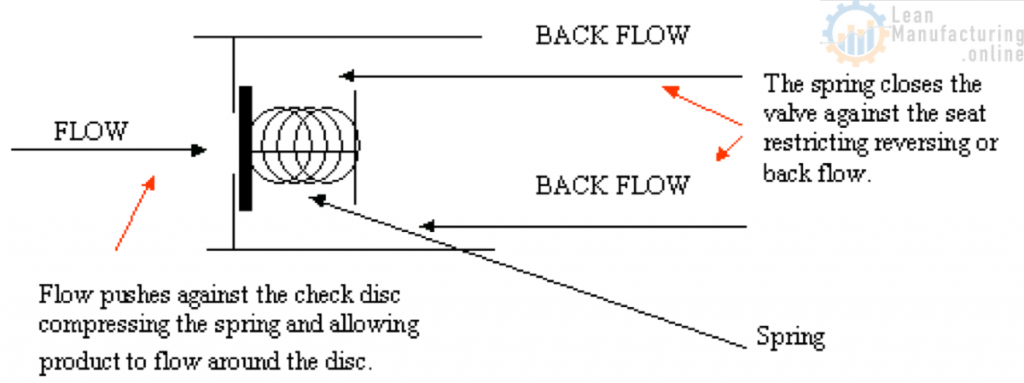

A Check Valve is used to prevent material from back flowing or reversing through a product line.

It is very important when reassembling a check valve to ensure it is put together the correct way. Some check valves are held together by Tri-Clover Clamps and can easily be put together backwards. To ensure this doesn’t happen, remember that the seat needs to be replaced into the machined end of the housing. There is only one end that is machined.

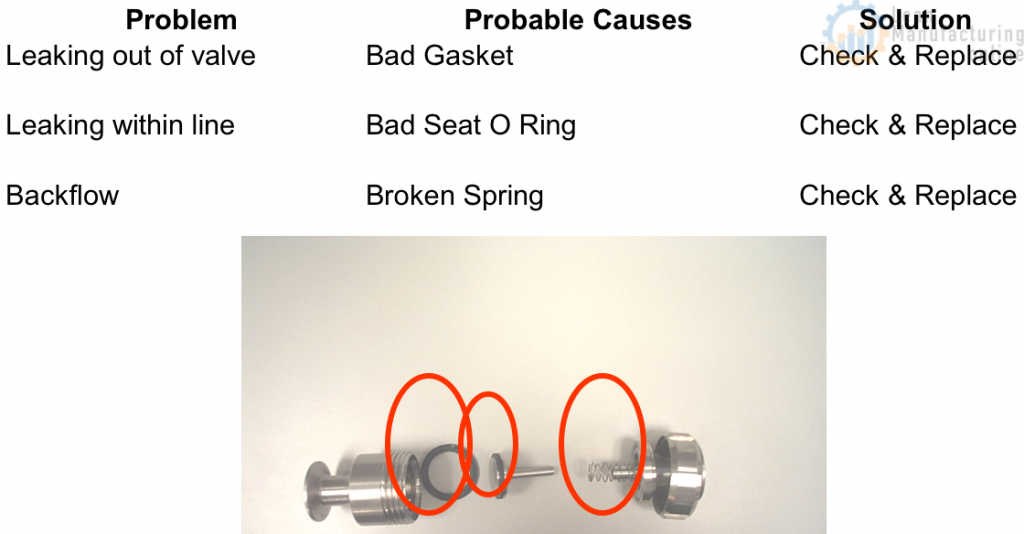

The gasket, seat O ring, and spring that are circled in the picture below occasionally need to be replaced due to wear.

Plunger Valves

Plunger valves are air and spring operated. The air or spring is used to move the plunger ON and OFF of a metal seat for Opening and Closing. This happens when a signal is received from the computer in the solenoid in the green control top of the plunger valve. This opens the solenoid allowing air to pass through the control top and down to the yoke which in turn raises the stem, causing an opening for ingredient to pass through.

The most common failures on plunger valves are the body

O-Ring marked on the figure to the right. The gasket marked

on the figure to the right. And the seat marked on the

figure to the right.

The seat is very easy to replace and requires the disassembly

of the bottom part of the valve. Once this is done the seat needs

to be cut off of the stem and the new seat is easily pushed over

the end of the stem.

The O-Ring needs to be pulled out with an O Ring Puller and

replaced with an O-Ring of the appropriate size.

Plunger Valves & Limit Switches

The limit switches are important in that if they are not met, there will be no recognition that the valve is open or closed. On Product line, for example, which are mass flow, it is very important that the limit switches are met, otherwise no other tank in the department will be able to receive that ingredient. Limit switches are not met when the stem does not make contact with either limit switch. This could be caused by a lack of airflow to the valve not allowing it to fully open or close.

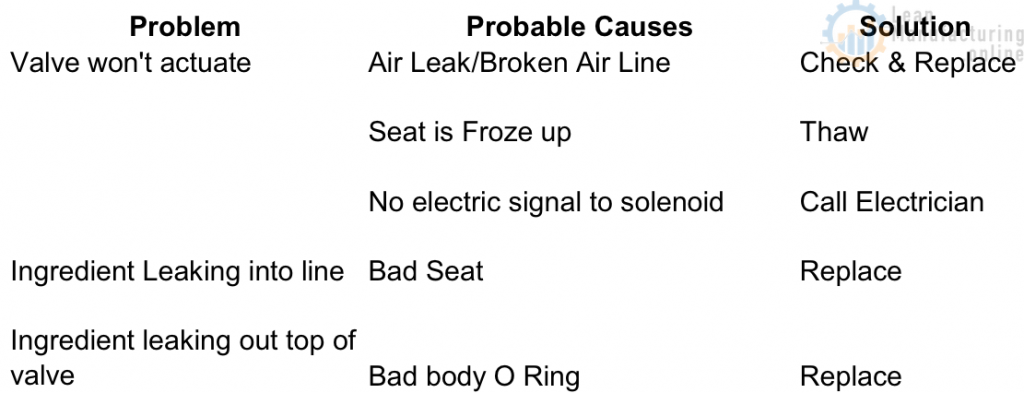

Plunger Valves Troubleshooting

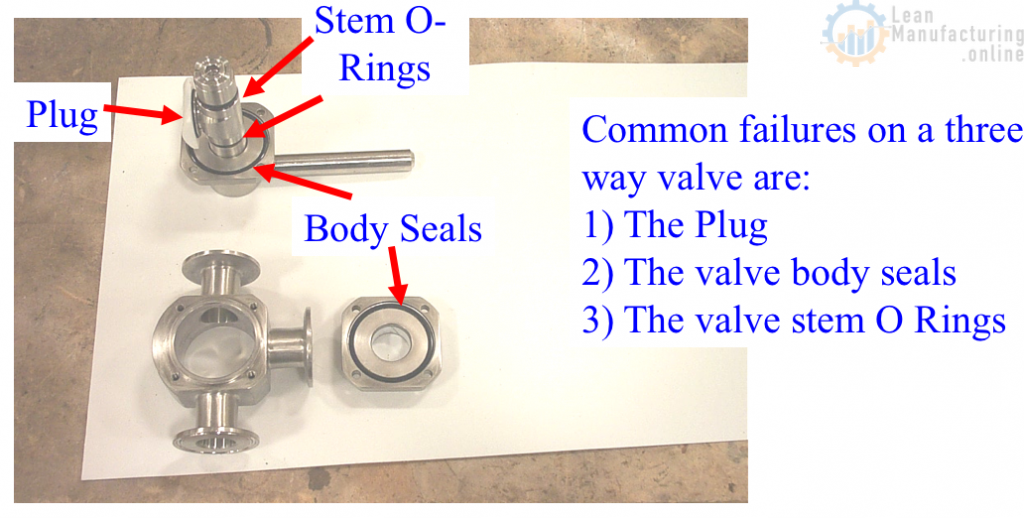

Plug Valve (Three Way Valve)

Tuchenhagen Valves

Tuchenhagen valves are used in much the same way as plunger valves that are found in the plant. They are used to divert product

and to open and close piping to allow product to pass through.

Valve Knowledge

Assess knowledge gained by member of autonomous maintenance team and measure the effectiveness of training materials.

Valve Competency

Assess knowledge gained by associates by demonstrating skill with “Hands-on” practical exercises on physical models.