Black Belt Training

Measurement System Analysis (MSA)

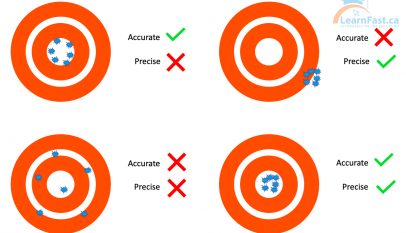

The Challenge with Data Collection The data you collect may only be as good as the system you use to collect it. Repeated measures of a variable give different results. Data collected from a measurement system that is not “accurate or precise” may lead to an incorrect business decision: Rejecting…

Read More »Sampling

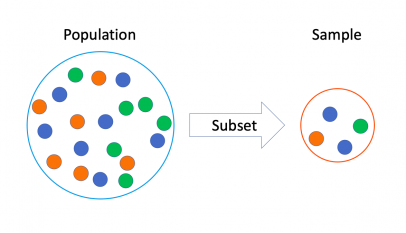

In the Measure phase of a Six Sigma project, the team needs to collect data to measure the baseline performance of Y. Since it’s not always possible to measure every item n the population, samples are collected. So you might be wondering, “How do you sample?” and, “How much do…

Read More »Data Collection

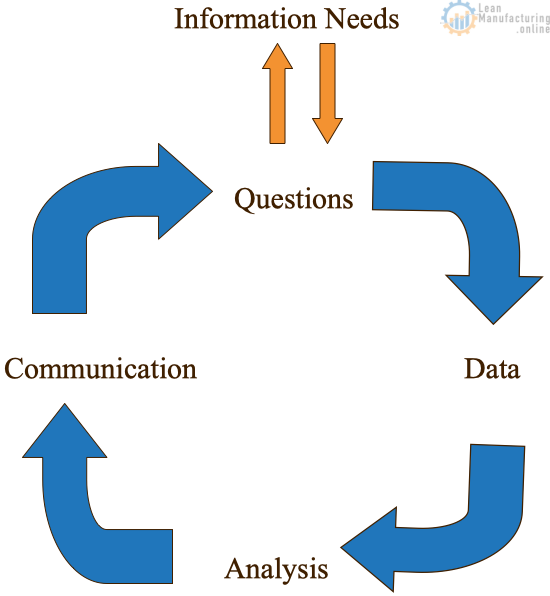

Data and facts are fundamental to every quality improvement effort. Without the facts, our problem-solving efforts are reduced to a “guessing game”. Generating Information Formulate the question we’re trying to answer Collect the data relating to that question Analyze the data to answer the question Clearly present the data to…

Read More »Translating VOC into CTQ’s

Voice of the Customer Customer focus drives such questions as: Why are we in business?Where do we need to be in the future?What is the source of our ‘Competitive Advantage’? Customers align cross functional organizations: What drives purchasing behavior?What is a defect, what is Value? Who is the Customer? All…

Read More »