DMAIC

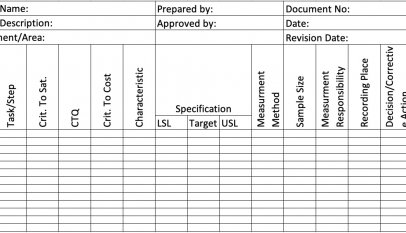

Control Plan – Monitoring system

Objectives What are control plans, and what is the purpose of control plansWhat does it do?Putting the control plan into placeControl ChartsIntegrating control charts and plans Control and Response plans must be prepared to ensure the following: Creating and aligning the system, structure, and processesComplete documentation of the processes and…

Read More »Cpk vs. Ppk? What Is The Difference and Why It Is Important

Cpk: Process Capability Index. Adjustment of Process Capability (Cp) for the effect of non-centred distribution. Cpk tells you what the process is CAPABLE of doing in the future, assuming it remains in a state of statistical control. Ppk: Process Performance Index. Adjustment of Process Performance (Pp) for the effect of…

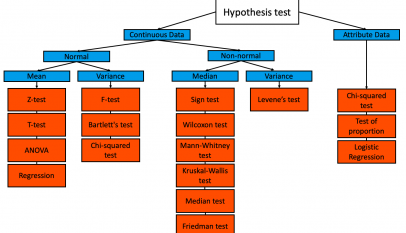

Read More »Introduction to Hypothesis Testing

Hypothesis Testing is a statistical tool, that allows the resemblance of two or more process attributes – mean, median, and standard deviation. It provides a method to determine differences. An important part of a conclusion reached based on random sampling (statistical inference) A hypothesis is a statement we want to…

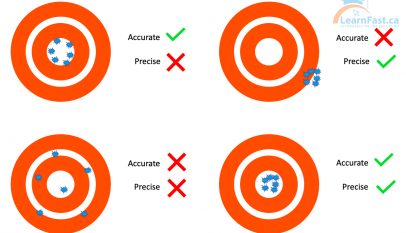

Read More »Measurement System Analysis (MSA)

The Challenge with Data Collection The data you collect may only be as good as the system you use to collect it. Repeated measures of a variable give different results. Data collected from a measurement system that is not “accurate or precise” may lead to an incorrect business decision: Rejecting…

Read More »