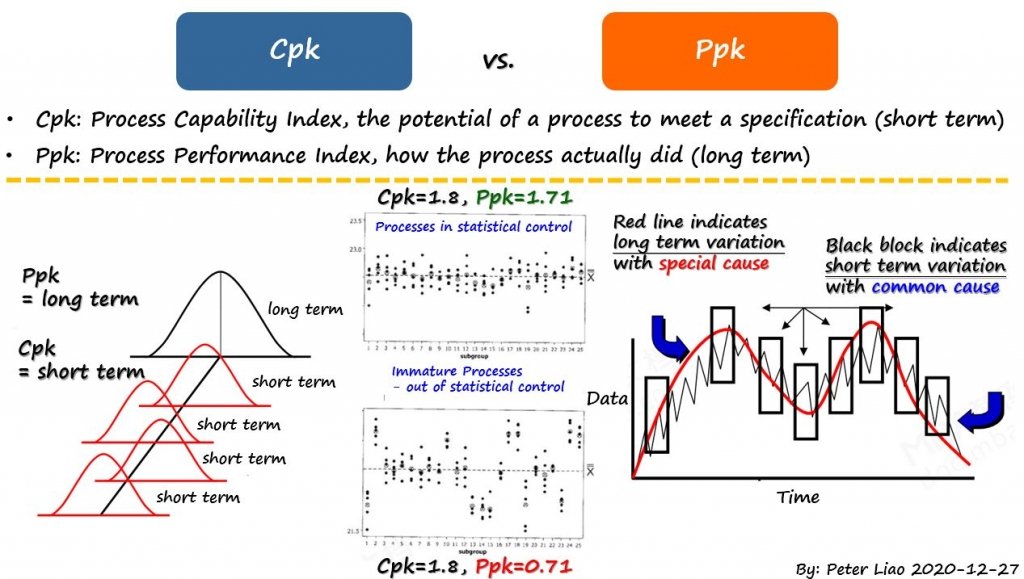

Cpk: Process Capability Index. Adjustment of Process Capability (Cp) for the effect of non-centred distribution. Cpk tells you what the process is CAPABLE of doing in the future, assuming it remains in a state of statistical control.

Ppk: Process Performance Index. Adjustment of Process Performance (Pp) for the effect of non-centred distribution. Ppk tells you how the process has been performed in the past. You cannot use it to predict the future because the process is not controlled.

Differences Between Cpk and Ppk

1. Cpk is the potential of a process to meet a specification (short term). It is used to measure the potential capability of a system to meet customer needs.

2. Ppk is how the process did (long term). It is used to measure the performance of a system to meet customer needs. Use it when you want to measure a system’s actual process performance.

3. Cpk considers variation within subgroups (common cause), and Ppk considers total variation, which means variation between and within subgroups ( common cause and special cause).

LinkedIn post by Peter Liao

Very useful