DMAIC

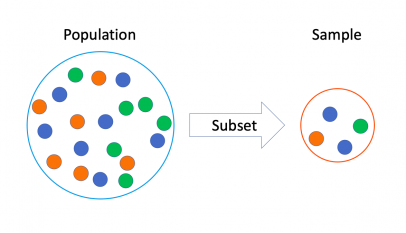

Sampling

In the Measure phase of a Six Sigma project, the team needs to collect data to measure the baseline performance of Y. Since it’s not always possible to measure every item n the population, samples are collected. So you might be wondering, “How do you sample?” and, “How much do…

Read More »Lean Six Sigma Green Belt Exam

As a Lean Six Sigma (LSS) professional, staying on top of your game requires constant skill evaluation and development. It's crucial to identify areas of strength and opportunities for improvement to ensure you're delivering the highest level of expertise.

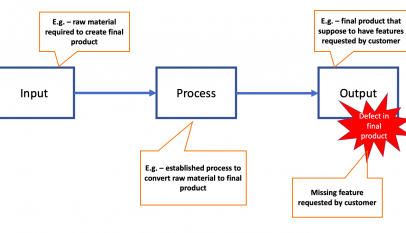

Read More »Translating VOC into CTQ’s

Voice of the Customer Customer focus drives such questions as: Why are we in business?Where do we need to be in the future?What is the source of our ‘Competitive Advantage’? Customers align cross functional organizations: What drives purchasing behavior?What is a defect, what is Value? Who is the Customer? All…

Read More »Defining Problem

A problem is an undesirable situation which may be solvable by some agent although probably with some difficulty.

Read More »