Lean Six Sigma

Improve Phase. Identify The Vital Xs And Implementable Solutions

To make certain that you are heading down the right path, you should determine whether the Xs you have identified (vital Xs) as being in need of improvement are critical elements or operating parameters.

Read More »Design of Experiments

Design of experiment: used to select product characteristics and process parameters to obtain desired product and process performance.

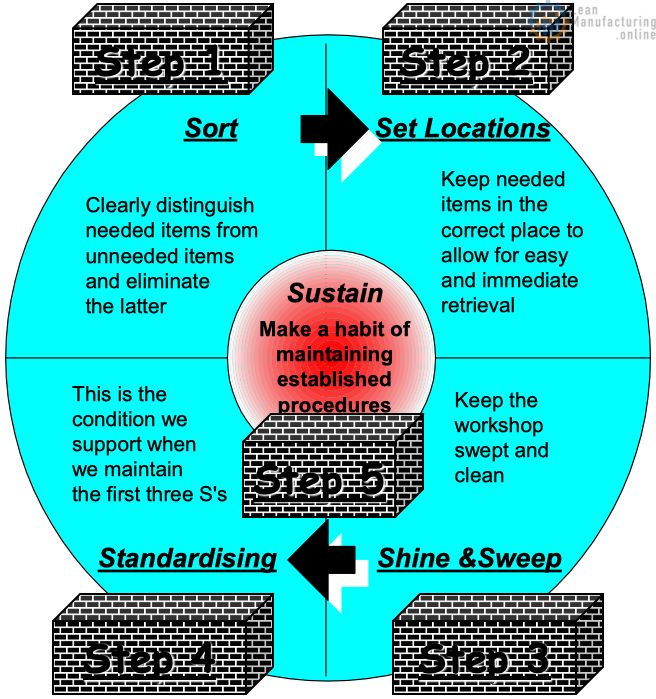

Read More »Japanese terminology for 5S is seiri, seiton, seiso, seiketsu, and shitsuke

A program to reduce operational steps and improve the overall cleanliness of a work area making it safer and more productive. Step 1. Sort Removing from the workplace all items that are not needed for current production operations. Leaving only the bare essentials: Sort out what is really necessary and…

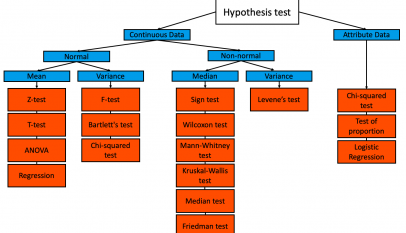

Read More »Introduction to Hypothesis Testing

Hypothesis Testing is a statistical tool, that allows the resemblance of two or more process attributes – mean, median, and standard deviation. It provides a method to determine differences. An important part of a conclusion reached based on random sampling (statistical inference) A hypothesis is a statement we want to…

Read More »