Lean

Jidoka

Quality is built in during every step of the manufacturing process. If equipment malfunctions or defect is detected, machine in question will automatically stops, dragging down the rest of production until the problem is resolved. For the Just-In-Time system, every single part that is made and supplied must meet predetermined…

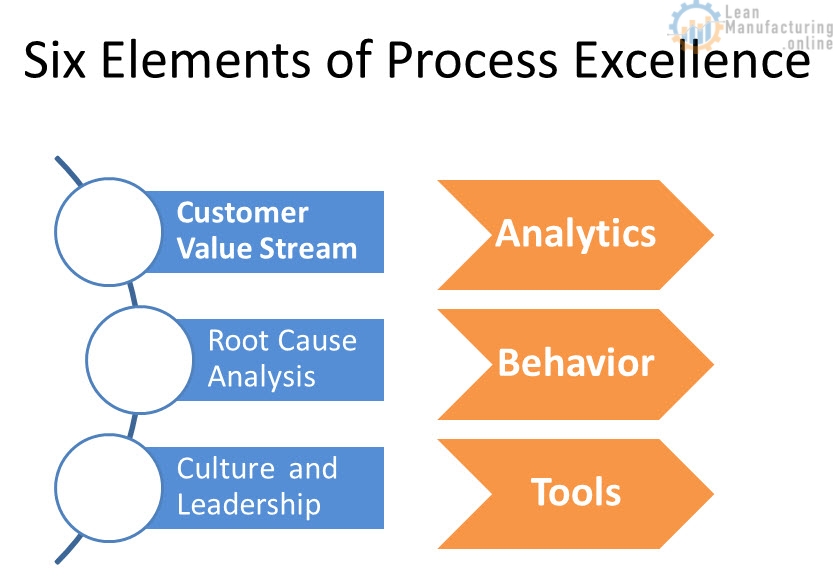

Read More »6 Elements of Process Excellence

First let’s review “what” is Process Excellence, or first three elements of the process: Customer Value Stream (CVS) processes that run flawlessly from one end to another; delivering value to the customer when they want to where they wanted to how they wanted with little or no waste. Root Cause…

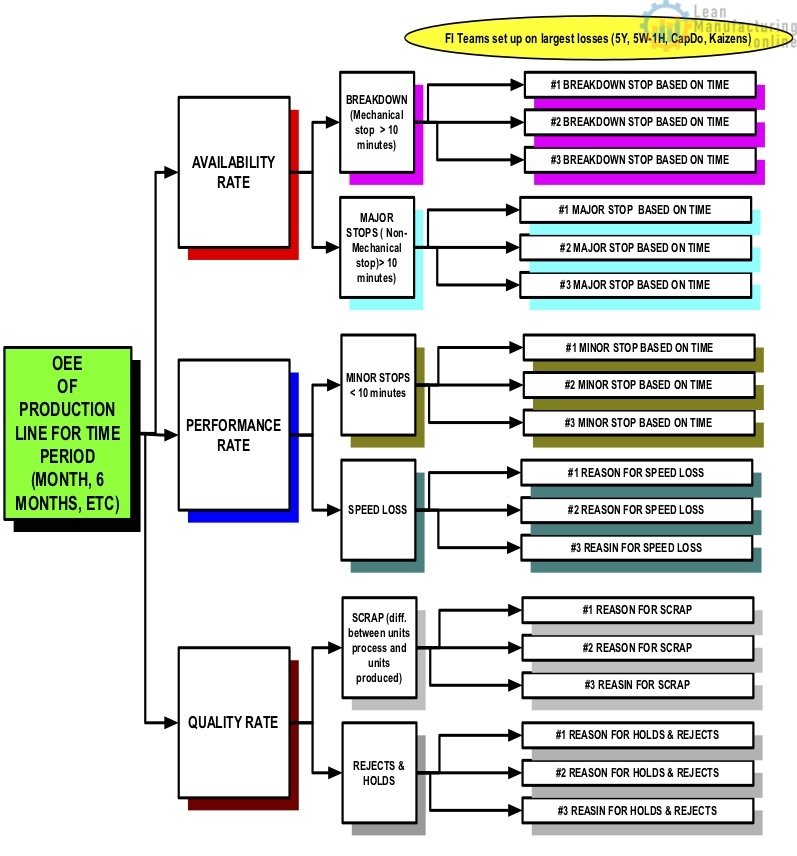

Read More »Major Stops – The Real Costs

Plant reliability is the key underpinning of an efficient supply chain. Without the ability to produce what is needed, when it is needed and, in the quantity needed, the entire Supply Chain must cover itself by placing inventory at critical areas thus driving up working capital and total costs. Excessive…

Read More »DMAIC – Measure – Stakeholder Analysis

Definition of Stakeholder Any individual or group can either influence or might be affected by the project. Their support is key to the success of the project. Some examples of key stakeholders: CustomersOperations ManagementHourly and staffSuppliers and end-usersRegulatory Body A stakeholder can offer both support and resistance: Technical or functional…

Read More »