Lean

Types of material replenishment systems

Material replenishment is a critical component of effective supply chain management. There are several types of material replenishment systems available, each with its own strengths and weaknesses. In this post, we will explore the different types of material replenishment systems including the Kanban System, Just-In-Time (JIT) System, Material Requirements Planning…

Read More »Lean Manufacturing: The Key to Increased Efficiency and Productivity

Lean manufacturing encourages continuous improvement and employee engagement, which leads to increased innovation and adaptability to changing market conditions.

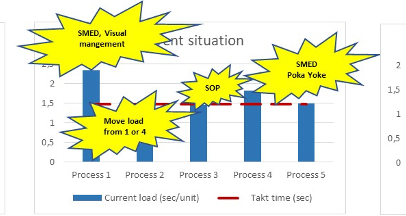

Read More »Workload balancing and a case in manual assembly

In this article, I will briefly run through the process of workload balancing; what is it, what does it do, and how do you do it? I will follow up that description with an actual case in a manual assembly process of a shutter used in an internet connector. It…

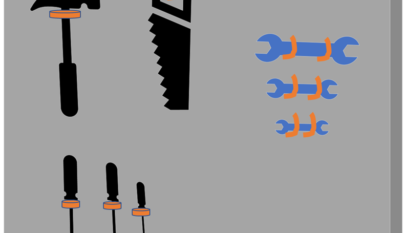

Read More »How can Shadow boards improve the efficiency of your process?

Shadow boards are tools which help organize workstations, setup carts, tool cribs and practically anything that needs organizing! Let me take you through an example of how a company increased their productivity by 35% just by installing a simple shadow board. Shadow boards help find a home for every object;…

Read More »