Failure is not something shameful; it’s a complex story of missed opportunities and overlooked details. It refers to all the tiny things that didn’t go according to plan, from the person who was too exhausted to notice an error to the machine that wasn’t calibrated properly. It encompasses the methods that were insufficient, faulty materials, unclear management and challenging environments.

Often, when we try to solve a problem, we realize that it is not as simple as it appears. There are various factors that contribute to it. For instance, ‘Method’ can cause issues due to lack of clarity, improper planning, or unsuitable procedures. Similarly, ‘Material’ can lead to errors when there is too much variability, or items are noncompliant.

Mechanical issues such as sensor failures or uncalibrated instruments are predictable and preventable, but they can affect the system’s performance. On the other hand, management issues, such as poor communication, unclear strategies, and insufficient incentives can weaken even the most robust system.

External conditions, from severe weather to network outages, can be as influential as human action within the context of a situation.

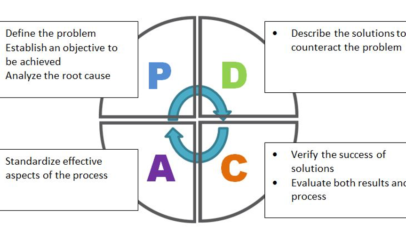

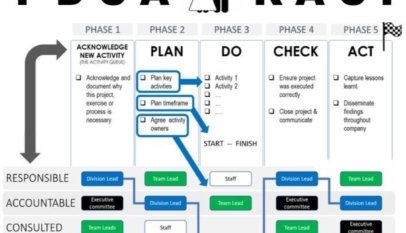

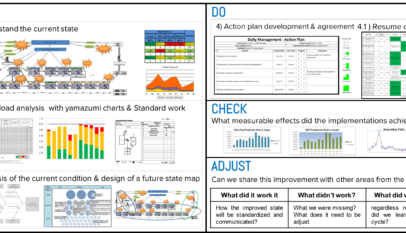

Crafting a solution begins with identifying and addressing key factors.

Human Factors:

- Boredom

- Carelessness

- Confusion

- Disengagement

- Disobedience

- Distraction

- Forgetfulness

- Incapability

- Inexperience

- Manipulation

- Misidentification

- Misunderstanding

- Noncompliance

- Slowness

- Tiredness

- Unawareness

- Undiscipline

- Unfitness

- Lack of motivation

- Lack of skill

Methodological Factors:

- Confusing methods

- Inadequate planning

- Incapability in execution

- Incorrect procedures

- Omissions in process

- Outdated practices

- Unavailability of necessary methods

- Unclear instructions

- Undefined processes

- Unplanned actions

- Unsuitability of methods

Material Factors:

- Incorrect amounts

- Contamination

- Defects

- Deformities

- Discoloration

- Expiry

- Incorrect items

- Noncompliance with standards

- Unavailability

- Undefined quality

- Incorrect valuation

- High variability

Mechanical Factors:

- Abuse of machinery

- Control failures

- Corrosion

- Degradation

- Disconnection

- Erosion

- Inadequate installations

- Insulation failures

- Obsolescence

- Operational failures

- Overloads

- Programming errors

- Sensor malfunctions

- Setup failures

- Software bugs

- Uncalibrated equipment

Managerial Factors:

- Poor accountability

- Insufficient capability

- Inadequate capacity

- Poor communication

- Unresolved conflicts

- Disengagement

- Low follow-up

- Unclear goals

- Missing incentives

- Unclear information

- Poor performance

- Unclear priorities

- Poor resourcing

- Low retention

- Poor safety policies

- Unclear strategy

- Poor teamwork

- Lack of training

- Lack of support

Environmental Factors:

- Bullying and mobbing

- Crime

- Diseases

- Dirt and dust

- Energy shortages

- Earthquakes

- Floods

- Extreme heat or icing

- Poor illumination

- Unavailability of labour

- Legal constraints

- Lightning strikes

- Network outages

- Noise

- Power failures

- Shortages in staff

- Supply chain disruptions

- Space constraints

- Traffic issues

- Utility failures

- Severe weather conditions

We must take assertive measures to identify and address these crucial factors to ensure success and prevent failure. Let us take ownership of the situation and steer it in the right direction.