Tools

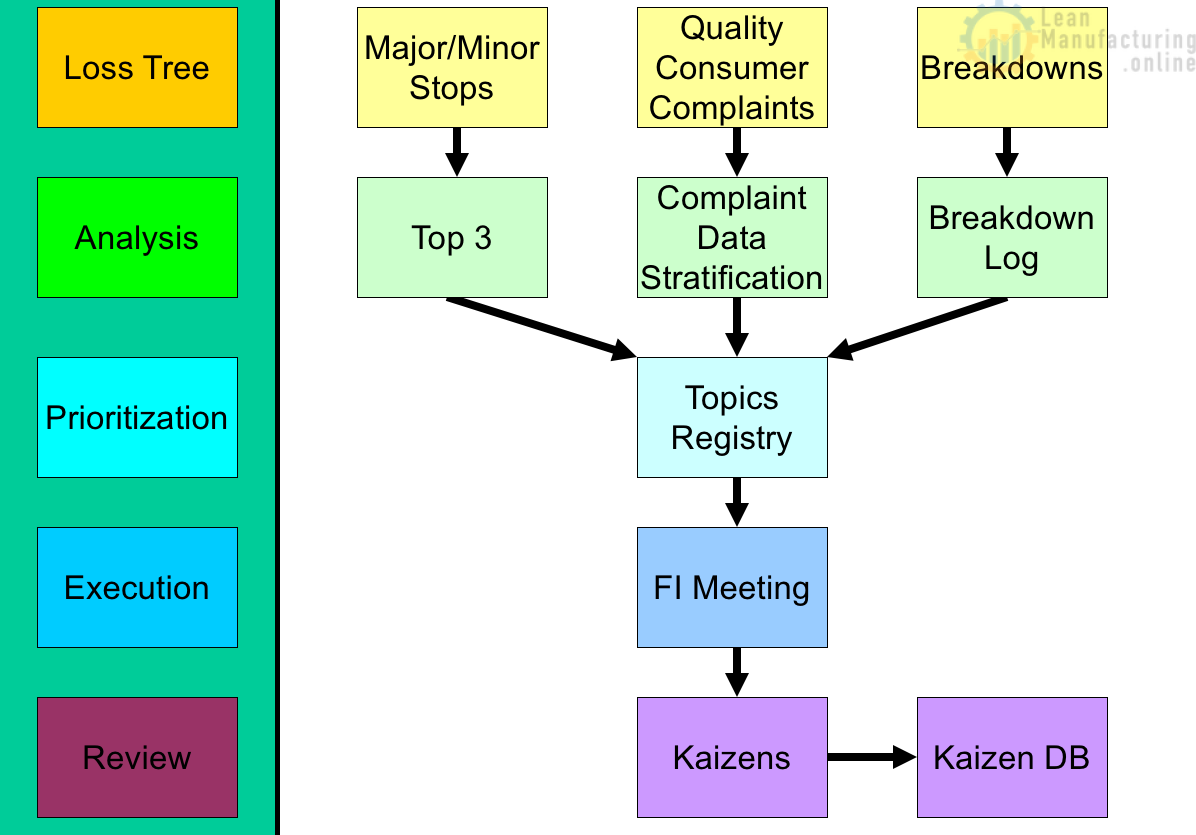

Focused Improvement Process

Focused Improvement Vision To eliminate all possible losses to improve safety and productivity, and reduce defects and production costs. To create a Continuous Improvement culture utilizing the Focused Improvement (Kaizen) technique to achieve maximum productivity of people, machinery, and material utilization, resulting in ZERO Accidents, ZERO Waste, ZERO Defects, ZERO…

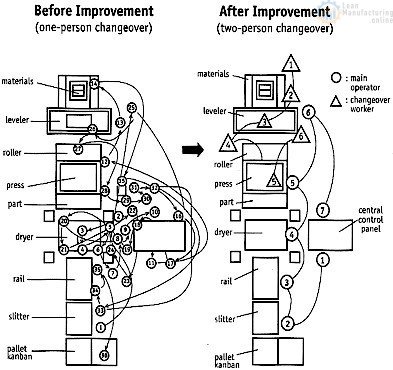

Read More »Changeover Time Reduction via Single Minute Exchange of Die (SMED)

Objective Review current status in changeover time for lead sites, identifying critical packaging lines in a key site, and carry out a pilot exercise to significantly reduce changeover time. Establish a plan to identify and implement appropriate techniques – e.g. SMED (Single Minute Exchange of Die) system this is a…

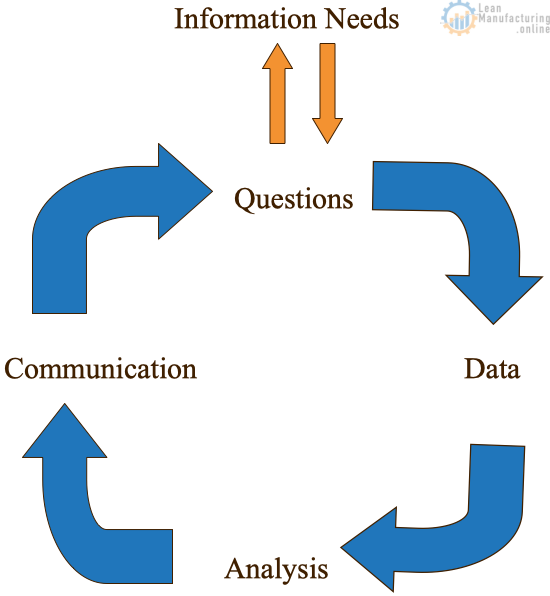

Read More »Data Collection

Data and facts are fundamental to every quality improvement effort. Without the facts, our problem-solving efforts are reduced to a “guessing game”. Generating Information Formulate the question we’re trying to answer Collect the data relating to that question Analyze the data to answer the question Clearly present the data to…

Read More »Definition of equipment loss

Time loss that results from sporadic (unscheduled) plant stoppage where plant or equipment ceases to function as specified. The failure can be classified into two types, one is the function-stoppage type and the other is the function deterioration type. The function-stoppage type failure is the one that occurs unexpectedly, while…

Read More »