Tools

Identifying Phenomena for Minor Stops – 6 Gens

Addressing minor stops requires a structured approach using the 6 Gens principles to shift from reactive problem-solving to proactive improvements, reducing downtime and enhancing productivity.

Read More »Unlocking the Power of FMEA: Essential Steps for Process Reliability

Failure Modes and Effects Analysis (FMEA) is a powerful tool for identifying potential failures in products, processes, or services. By systematically assessing risks, FMEA helps ensure reliability and safety, leading to continuous improvement. Here's a comprehensive guide to mastering the FMEA process.

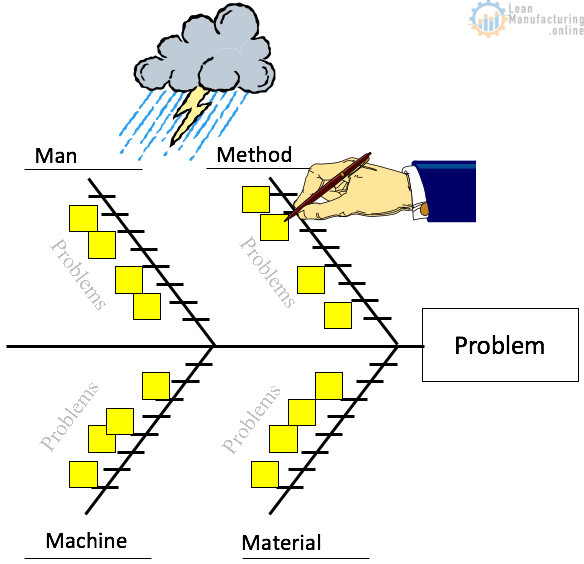

Read More »The Fishbone Diagram

What is a Fishbone Diagram? A Fishbone Diagram is a “Cause and Effect” diagram. The importance of the FBD is that it uses visual power to highlight the problems and the relationship between problems and their potential sources. When to use a Fishbone Diagram? When a simple approach is needed…

Read More »Avoiding OKR Mistakes and Misapplications

Navigating the OKR journey can sometimes be challenging. In the quest to effectively leverage Objectives and Key Results (OKRs), organizations can often encounter pitfalls and missteps. Our guide, "Avoiding OKR Mistakes and Misapplications," provides insights into common errors in OKR implementation and application. It offers practical strategies to sidestep these…

Read More »