Tools

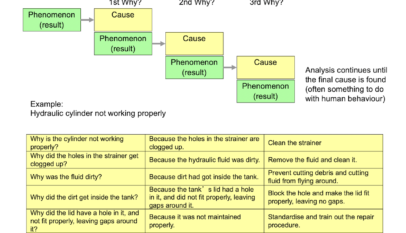

Why-Why Analysis

You will understand when it is necessary to find a root cause of a problem and use the Why-Why as a method to prevent problems from happening again.

Read More »Total Productive Maintenance and case on a stand-alone machine

In this article, I will briefly touch on the TPM concept and then describe how I used the elements; what I later learned through a TPS training by Toyota Engineering Corporation (TEC) was actually Equipment Kaizen. Anyway, we made the improvements through a Kaizen Event in 5 days, and it…

Read More »Spare Parts Administration

PM Element 7. Indicators The Importance of Spare Parts Administration Spare parts administration is crucial for organizations that rely on equipment to operate. If a breakdown or failure occurs, having spare parts on hand can reduce downtime, minimize production losses, and improve customer satisfaction. Additionally, a well-managed spare parts program can…

Read More »Safety, Health and Environment Investigation Report and Analysis

5 Why Analysis Blog Cap-Do Lean Six Sigma PM-analysis Root Cause Analysis Safety Safety, Health and Environment TPM

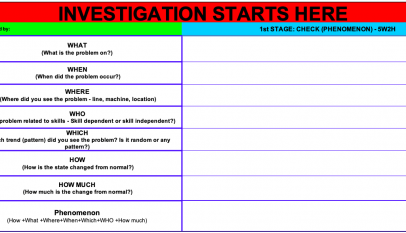

All modern manufacturing facilities use principles that “all accidents are preventable,” but sometimes incidents or accidents can still happen. Gathering as much data as possible and analyzing it to prevent a recurrence is essential. Investigation Report Let’s review the first part – [ Incident Reporting ] A. To be completed…

Read More »