Autonomous Maintenance

One Point Lesson – Flat Belts Inspection – Autonomous Maintenance

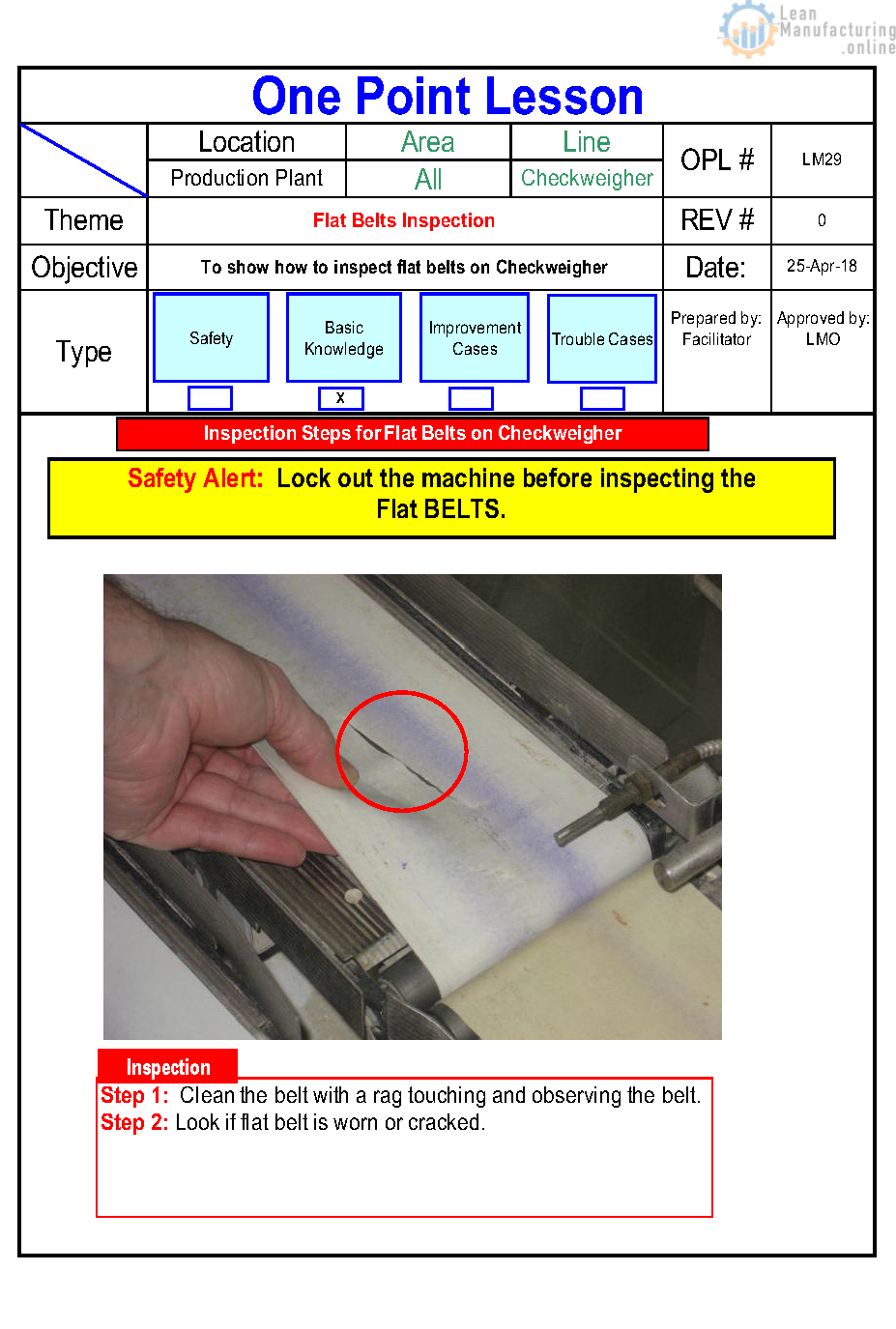

Step 1: Clean the belt with a rag touching and observing the belt. Step 2: Look if flat belt is worn or cracked.

Read More »Inspection Steps for Chains and Sprockets – Visual Standards Inspections

Step 1: Clean the sprocket with a rag touching and observing the sprocket. Step 2: Look for the following abnormalities: Worn teeth Misalignment Abnormality 1: Worn teeth teeth should not be rounded,teeth should not be chipped. Abnormality 2: Misalignment The sprocket must be aligned and perfectly perpendicular to the axis of…

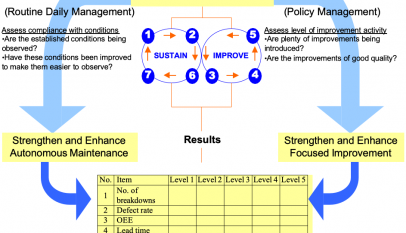

Read More »Implementation of AM Step 6 Standardization & AM Step 7 Full Self-management

AM Step 6 Activities Up to this stage, the Autonomous Maintenance activities have focused on the equipment, and in particular, the basic equipment conditions and the daily checks required to maintain them. The aim of Step 6, in addition to consolidating what has been done so far, is to expand…

Read More »Autonomous Maintenance 1st step – 3rd step

F-TAG (Tagging) • F-Tag should be attached to the following malfunctions: Wear, Play, Slackness Leakage Dust, Dirt Corrosion Adherence of raw materials, Deformation, Surface damage, Cracking Overheating, Vibration, Noise … Examples of “Fuguai” – Potential problems Categories of Fuguai Examples Examples of check point 1. Minor defects Dirtiness Scratches Play…

Read More »