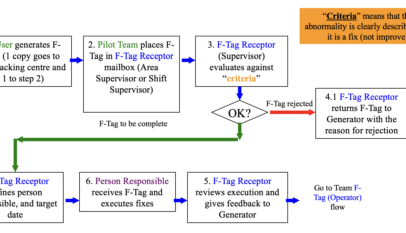

F-TAG (Tagging)

|

• F-Tag should be attached to the following malfunctions:

|

Examples of “Fuguai” – Potential problems

| Categories of Fuguai | Examples | Examples of check point |

| 1.

Minor defects |

Dirtiness

Scratches Play Looseness Abnormality Adhesion |

Dust, dirt, powders, oil, rust and paint

Cracking, collapsed, deformed, chipping, bends Shake, slip off tilting, eccentricity, wear, distortion, corrosion. Bolt, nut, gauge, cover, belt, chain; Looseness, Omission, Incorrect tightening, Excessively long bolt, Battered threads, Corrosion, Incorrect washer, Bolt direction, Double nut put in reverse. Abnormal sound, heat, vibration, offensive odor, discoloration, pressure Clogging, sticking, deposition, peeling off |

| 2.

Lubrication |

Leaking

Incorrect conditions Incorrect indicators |

Oil depletion, dirty oil, oil type (not known, inadequate), leak

Dirty oil support port, clogging, damage, deformation, collapsed pipe, storage condition, inadequate oiling equipment Dirtiness, damage, leak, wrong level indication |

| 3.

Source of contamination |

Products, Raw Materials

Hydraulic oil, Liquid Gasses Machining & Processing Other |

Leak, spilling, blowing off, scattering, overflow

Leak, spilling or permeation of fluid Leak, spilling air, gasses, steam, vapor, exhaust water Burrs, chips, packing, sputters, sparks, smokes, adhesive, paints Dropped parts |

| 4.

Hard to reach areas |

Cleaning / Inspection

Lubrication Operation |

> Equipment structure, cover, layout, foothold, space, installing height high or low, indicators inadequate |

| 5.

Quality defects |

Foreign maters

Manufacturing condition |

Leaking, overflow

Humidity, vibration, collision, temperature |

| 6.

Unnecessary things |

Equipment components,

Products, Tools, Jigs, Spare parts, Pipes |

Mess, disorder, |

| 7.

Safety concerns |

Incorrect conditions

Incorrect indicators |

Floor, Steps, Stairs; unevenness, cracks, peeling off, wear

Lighting; dark Safety devices; broken, worn stoppers, wear |

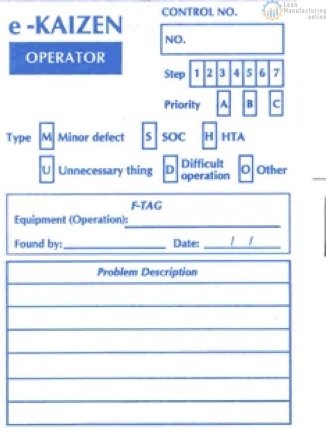

F-Tag Log

| Category | Operator | Maintenance |

| No. | Date | Priority | Type of

F-Tag |

Description of Problem | Result if left not repaired | Why did it become so?

(What is the cause?) |

Action | Person Responsible | Planned Date | Date Completed |

| / | ||||||||||

| / | ||||||||||

| / | ||||||||||

| / | ||||||||||

| / | ||||||||||

| / | ||||||||||

| / | ||||||||||

| / | ||||||||||

| / | ||||||||||

| / | ||||||||||

| / | ||||||||||

| / | ||||||||||

| / | ||||||||||

| / | ||||||||||

| / |

Note: Type of F-Tag; (M) Minor defect, (S) SOC, (H) HTA, (U) Unnecessary thing (D) Difficult operation (O) Other

F-Tags – Abnormality Tally Sheet

| Category of

Potential problems Location of F-Tags attached |

Dust, Dirt, Leak, Splash, Rust, Scratches | Chattering, Loosening, Missing | Wear, Broken, Bent | Chipping, Missing, Holes, Unevenness, Inclined | Abnormal noise, Excessive heat, Vibration, Odor, Discoloration, Abnormal movement | Hard to clean, Lubricate and Inspect | Other | |

| External surface of equipment | Body, Covers, Piping, Wiring,

Valves, Pneumatic set, etc. |

|||||||

| Door / inside of covers | Safety cover, Operating/ control panel, Inspection hole, etc. | |||||||

| Associated equipment | Hydraulic unit, Lubrication tank. | |||||||

| Peripheral equipment | Measurement , jigs, Tools | |||||||

| Transportation system | Chute, Conveyors, Turntable, etc./ | |||||||

| Production floor around the equipment | Floor, Pit under the floor, wall, etc. | |||||||

| Others | ||||||||

1st Step – “Initial-Clean” Diagnosis Checklist

Equipment ID

| Items | Check the following | Evaluation | Comments | |

| 1 | Main body | How well are the dust, oil and grease, and chips removed?

How about the condition of work and tools? (Such area as tools and Jigs surfaces, chuck, sliding portion, chute, frame, bed, piping and wiring, etc.) |

1 – 2 – 3 – 4 – 5 | |

| 2 | Free from loosening, chattering, vibration, excessive wear and heat build-up (in such areas as bolts, nuts jigs, Rotating portions, Sliding portions and Chute, etc.) | 1 – 2 – 3 – 4 – 5 | ||

| 3 | Sub-equipment | Free from dust, oil and grease or any other foreign materials.

(Cylinders, Solenoids, Air line combination units, Motors, Limit switches, Belts, Proximity switches, photoelectric Switches, Control panels etc. |

1 – 2 – 3 – 4 – 5 | |

| 4 | Free from loosening, chattering, vibration, excessive wear and heat built up, and roaring.

(Motors, Solenoid valves, Limit switches, Installation board, relays, Wiring, Bolts and Nuts, etc.) |

1 – 2 – 3 – 4 – 5 | ||

| 5 | Lubrication | Free from dust, dirt and oil stain.

(Lubricator, Oil cups, Measuring instruments, Cap of oil filler, Oil supply piping, etc.) |

1 – 2 – 3 – 4 – 5 | |

| 6 | Proper oil level and oil flow rate, free from loosening, chattering, and vibration.

(Check for contaminated oil, oil deterioration, Loose piping joints, Valve, Speed control, Oil temperature, etc.) |

1 – 2 – 3 – 4 – 5 | ||

| 7 | Around

the equipment & machine |

*Cleaning condition of tools, measuring instruments and gauges, and spare parts.

*Are the cover, name plate and label in good conditions? *Are the unnecessary parts, products and replacement parts in good order? |

1 – 2 – 3 – 4 – 5 | |

| 8 | *Are the accepted products properly segregated from rejected products?

*Are the proper passages provided? *No flying dust from adjacent equipment. |

1 – 2 – 3 – 4 – 5 | ||

| 9 | Countermeasures for

the source of contamination & improving hard-to-access area |

Has any list showing the sources of dust, dirt, oil leakage and the areas difficult to keep clean been prepared?

And Is there any Action Plan for cleaning? |

1 – 2 – 3 – 4 – 5 | |

| 10 | *Have the cover and housekeeping utensils been improved?

*Is there any point you should check while performing the housekeeping? *Has the responsibility for cleaning the areas been properly assigned to each operator? |

1 – 2 – 3 – 4 – 5 | ||

| Summarize up Floor Diagnosis | Σ | |||

| 11 | Group Activity | Is Annual Target clear? And visualize relationship to Company Target clearly? | 1 – 2 – 3 – 4 – 5 | |

| 12 | (TPM Activity Board) | Are OEE, # of Breakdown, Quality Defects etc. tracking periodically? | 1 – 2 – 3 – 4 – 5 | |

| 13 | Are F-Tags organized visually, effectively? | 1 – 2 – 3 – 4 – 5 | ||

| 14 | Are One-Point Lessons made effectively? And Does Transmitted Training implement by One-Point Lessons.? | 1 – 2 – 3 – 4 – 5 | ||

| 15 | Is Autonomous Maintenance allocated to all team members clearly?

Is Specific responsibility of members clear? |

1 – 2 – 3 – 4 – 5 | ||

| Summarize up Group Activity | Σ | |||

| *Note | Σ | (PASS) (FAIL) |

* NOTE; PASS MARK is more than 80% (Σ(Floor-diagnosis(1-10) Evaluation Point + Σ(Group Activity(11-15) Evaluation Point))

2nd Step – “Countermeasure for source of contamination & hard-to-access area” Diagnosis Checklist

Equipment ID

| Items | Check the following | Evaluation | Comment | |

| 1 | Review 1st Step | Is cleaning level of 1st step (Initial clean-up) good, and is it maintained? | 1-2-3-4-5-6-7-8-9-10 | |

| 2 | Countermeasure for

Equipment main body |

Are the cause sources such as dirt, dust, oil leakage, air leakage summarized into a list, and are countermeasures for the causes taken? | 1 – 2 – 3 – 4 – 5 | |

| 3 | Are the hard-to-access areas summarized into a list, and are the state of contrivance and improve good?

(Are cleaning tool covers removed, put in order and arrangement.) |

1 – 2 – 3 – 4 – 5 | ||

| 4 | Countermeasure for

Sub-equipment |

Are the causes of trouble such as dirt, dust, oil leakage, air leakage summarized into a list, and are countermeasures for the causes taken? | 1 – 2 – 3 – 4 – 5 | |

| 5 | Are the hard-to-access areas summarized into a list, and are the state of contrivance and improve good?

(Are cleaning tool covers removed, put in order and arrangement.) |

1 – 2 – 3 – 4 – 5 | ||

| 6 | Around

the equipment & machine |

Are the source of contamination such as dirt, dust, oil leakage, air leakage put F-TAG, and summarized into a list, and are temporary action taken? | 1 – 2 – 3 – 4 – 5 | |

| 7 | Are the hard-to-clean areas, put F-TAG and summarized into a list, and are improved?

(Are cleaning tool covers removed, put in order and arrangement.) |

1 – 2 – 3 – 4 – 5 | ||

| 8 | Visual Control | Is Visual Control conducted effectively such as the follows;

Gages normal operating range, Critical Nuts & Bolts match mark. Hoses & Pipes color coded by product and flow direction Motors & Drives marked with rotation arrows? Lubrication type identified? And MAX-MIN marked? |

1-2-3-4-5-6-7-8-9-10 | |

| Summarize up Floor Diagnosis | Σ | |||

| 9 | Group Activity

(TPM Activity Board) |

TPM Activity Board being used?

* Are OEE, # of Breakdown, Quality Defects etc. tracking periodically * Are F-Tags organized visually, effectively? * Are One-Point Lessons made effectively? And Does Transmitted Training implement by One-Point Lessons.? |

1-2-3-4-5-6-7-8-9-10 | |

| 10 | Is there any plan to maintain and improve Equipment Basic Conditions?

* Action plan for Improvement of 2nd Step * How to allocate Autonomous Maintenance Activity to all team members (Roll-Assignment Table, Map) |

1 – 2 – 3 – 4 – 5 | ||

| 11 | Is there any good improvement example of action for source of contamination? | 1 – 2 – 3 – 4 – 5 | ||

| 12 | Is there any good improvement example of action for Hard-to Access area, Visual Control? | 1 – 2 – 3 – 4 – 5 | ||

| Summarize up Group Activity | Σ | |||

| *NOTE | Σ | (PASS) (FAIL) |

NOTE; PASS MARK is more than 80% (Σ(Floor-diagnosis(1-8) Evaluation Point + Σ(Group Activity(9-12) Evaluation Point)).

3rd Step – “Preparation of tentative autonomous maintenance standards” Diagnosis Checklist

Equipment ID

| Items | Check the following | Evaluation | Comment | |

| 1 | Review 1st Step & 2nd Step | Are 1st Step (Initial clean-up) conditions and 2nd Step improved level maintained? | 1-5-10-15-20 | |

| 2 | Cleaning & Inspection Standard | (Cleaning & Inspection standard)

Is the standard made out according to the equipment and location? Are cleaning & Inspection section, location and assignment specified? Are methods and tools specified? Are Cleaning & Inspection Time and Frequency properly visualized and implemented? Are the contents clear and understandable by everybody? |

1-2-3-4-5-6-7-8-9-10 | |

| 3 | (Tightening)

Are bolts and nuts loose? Are there any bolts and nuts missing? |

1 – 2 – 3 – 4 -5 | ||

| 4 | Lubrication Standard | (Lubrication standard)

Are kind of lubrication, amount, cycle, method and assignment specified? Are proper labels applied to lubrication points? Is the oil ready for lubrication all the time? Is the oil storage location tidy? |

1-2-3-4-5-6-7-8-9-10 | |

| 5 | Awareness of one’s own role in making the standard | Are the improvement and new ideas for Easy-to do and Visual Control implemented actively? | 1 – 2 – 3 – 4 -5 | |

| Summarize up Floor Diagnosis | Σ | |||

| 6 | Group Activity

(TPM Activity Board) |

TPM Activity Board being used?

* Are OEE, # of Breakdown, Quality Defects etc. tracking periodically * Are F-Tags organized visually, effectively? * Are One-Point Lessons made effectively? And Does Transmitted Training implement by One-Point Lessons.? |

1 – 2 – 3 – 4 -5 | |

| 7 | Is Activity observed accordance with Autonomous Maintenance Standard? | 1 – 2 – 3 – 4 -5 | ||

| 8 | Is Autonomous Maintenance Standard up to date by Team? | 1 – 2 – 3 – 4 -5 | ||

| 9 | Is Equipment Breakdown Log tracked by team? And Is Breakdown Analysis implemented? | 1 – 2 – 3 – 4 -5 | ||

| 10 | Is Skill-Training for operators implemented periodically? | 1 – 2 – 3 – 4 -5 | ||

| Summarize up Group Activity | Σ | |||

| *NOTE | Σ | (PASS) (FAIL) |

NOTE; PASS MARK is more than 80% (Σ(Floor-diagnosis(1-5) Evaluation Point + Σ(Group Activity(6-10) Evaluation Point))

Application Form for Autonomous Maintenance Step Diagnosis

| STEP | 1 | 2 | 3 | 4-1 | 4-2 | 4-3 | 4-4 | 4-5 | 5 |

|

Manager

Supervisor

Team Leader

| Team Member | Responsibility | Step Diagnosis Applied Machine ID; | |

| 1) | |||

| 2) | |||

| 3) | |||

| 4) | |||

| 5) | |||

| 6) | |||

| 7) | |||

| 8) |

Activity Log

When (Who) What How

SOCS & HTA Matrix

Equipment ID

| Category | Items | # | # | # | # | # | # | # |

| Where is it seen? | ||||||||

| Countermeasure for source of contamination | Describe the state of dirt. | |||||||

| What make dirty. | ||||||||

| When is it?

(During continuous processing, At start up…) |

||||||||

| How is it?

(Scatter?, Leak?…) |

||||||||

| Why is it? | ||||||||

| Countermeasure for

hard-to-access area |

What is it difficult?

(Cleaning, Inspection, Lubrication) |

|||||||

| Why is it difficult?

*High-Low *Behind *Hard-to-remove… |

||||||||

| Hints of improvement | Eliminate;

Eliminate the source of contamination its self, hard-to-access area its self. |

|||||||

| Combine;

Combine ” where” (Gather, Receive…) |

||||||||

| Replace;

Replace “where” (Change “where”) |

||||||||

| Simplify;

(Sucking, Washing) |

||||||||

| Log by One-point Lesson sheet | ID |

Routine Cleaning, Inspection & Lubrication Standard

| Dept. / Line | Machine ID | |||||||||||

| Diagram | No. | Item | Criterion | method | Tools | Time | Freq. | Person | ||||

| (Min) | S | D | W | M | Resp. | |||||||

|

||||||||||||

Note: (Freq.) S =Shift, D =Day, W =Week, if necessary, 2W=Two week, M =Month

Routine Cleaning Inspection & Lubrication Standard

| Dept. / Line | Machine ID | ||||||||||||||

| Diagram | No. | Item | Criterion | Method | Tools | Time | Freq. | Person | |||||||

| (Min) | S | D | W | M | Resp. | ||||||||||

|

Cleaning | ||||||||||||||

| 1 | Hydraulic unit | Be clean | Wipe | Rag | 5 | X | Op | ||||||||

| 2 | Main Motor | Be clean | Wipe | Rag | 3 | X | Op | ||||||||

| Inspection | |||||||||||||||

| 6 | Pressure gauge | £ 5 kgf | Visual | 0.5 | X | Op | |||||||||

| Lubrication | |||||||||||||||

Note: (Freq.) S =Shift, D =Day, W =Week, if necessary, 2W=Two week, M =Month

TPM Activity Board Requirements (Activity Board for First-line Small Group)

1. Policy & Implementation plan

1-1 Policy & Target

- Company / Factory policy & target / Department / Team policy & target (Annual, quarterly)

1-2 Action plan; TPM Master plan (Plant-wide and long term) / Team implementation plan (Annual plan and Quarterly)

2. Indicators (Measurables)

2.1 Tracking data (Monthly or Weekly)

- Productivity (Output per hour person)

- Quality (# of scrap and type of scrap)

- Cost (Overall Equipment Efficiency – Bottle neck machine)

- Delivery & Availability – Zero Breakdown calendar

(On-time delivery ratio, # of unscheduled breakdown, downtime, change over time

- Safety (Lost time injury)

2.2 Data collection (Daily or Every shift)

- # of breakdown

- # of scrap and type of scrap, rework

- Change over time , Time and Operation Analysis Chart

- # of minor stoppage

3. Action taken

- One Point lesson (Basic knowledge / Improvement case / Troubleshooting)

- Tag (Blue / Red ) & Tag-list (Fuguai list)

- 5-why analysis / P-M Analysis

- Autonomous Maintenance standards

4. Review of action taken

- # of One-point lesson

- # of Tag (Blue / Red)

- Step Diagnosis comment, score & sticker