AM Step 6 Activities

Up to this stage, the Autonomous Maintenance activities have focused on the equipment, and in particular, the basic equipment conditions and the daily checks required to maintain them. The aim of Step 6, in addition to consolidating what has been done so far, is to expand the operator’s role to cover the equipment’s surroundings as well as the equipment itself, continue to drive down the losses closer and closer to zero, and put the finishing touches to the team’s’ ability to manage their own work.

Workflow for Autonomous Maintenance Step 6 (Standardization)

- To review the operators’ role, and rationalise and standardise their ancillary work;

- To improve the level of sustainment achieved through Autonomous Checking, and build a system to maintain this improvement.

- Review what operators are doing (task content, purpose, method, current standards);

- Identify anything that has not been made optimally efficient and fully standardised in Steps 1 through 5 of the Autonomous Maintenance programme, and make suitable improvements.

- Standards for the movement of materials around the shop floor

- Standard operating procedure

- Basic work standards

- Standards for data recording, etc.

- Standards for managing moulds, tools, jigs, and measuring equipment

- Standards for managing spare parts

- Standards for process quality assurance, etc.

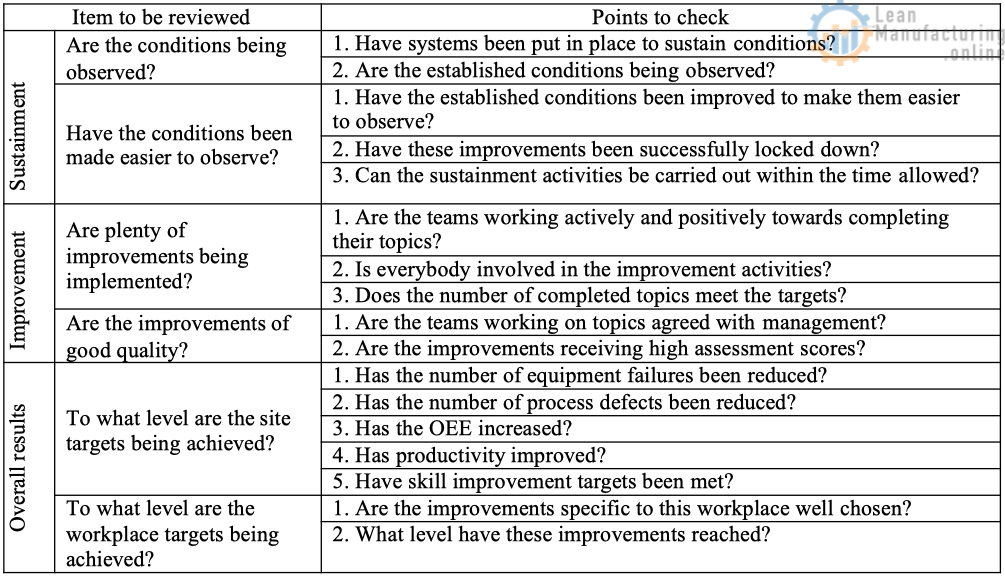

- Review the level to which conditions are being sustained through Autonomous Checking

- Introduce visual controls wherever possible

Step 6 Outline

What the standards should cover:

- Standards operating procedures

- Standards for the movement of materials around the shop floor

- Standards operating procedures

- Basic work standards

- Standards for data recording, etc.

- Standards for managing moulds, tools, jigs, and measuring equipment

- Standards for managing spare parts

- Standards for process quality assurance, etc.

Key points of Step 6

- At Step 6, the role of the operator is broadened to cover the work done in and around the equipment.

- Some of the routine tasks will involve WUS (waste, unevenness and strain) or other imperfections, when viewed from the objective of maximising the efficiency of the operators and the equipment.

- Combine small improvements to make big ones

- Promote ways of sustaining Autonomous Checking

AM Step 7 Activities

AIM of Step 7

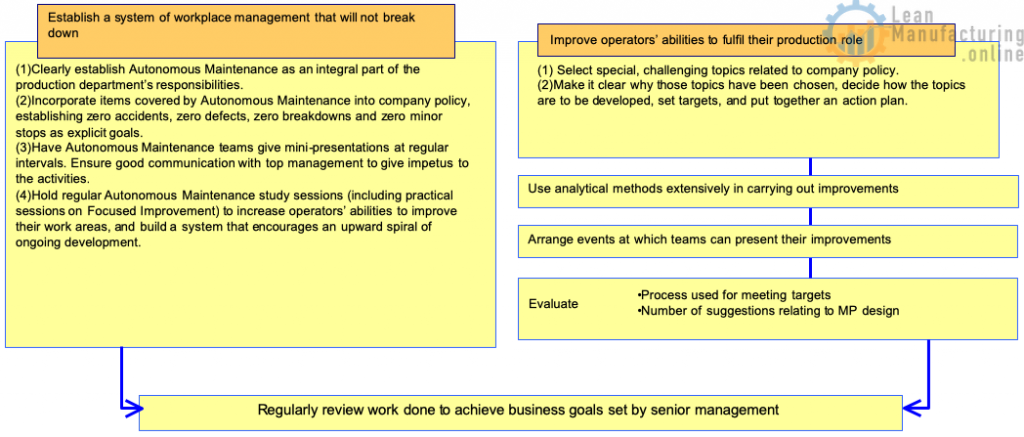

The aim of Step 7 is to consolidate all of the activities undertaken in Steps 1 through 6. By this stage, the operators should have gained real confidence about the changes they have made in the equipment and the workplace, and in their own self-development, and understand the positive results that these changes have produced.

The aim of Step 7 is to keep on encouraging them to see improvement as an endless process in which they can and must take the initiative. It should be used as an opportunity to reinforce the sense of participation and solidarity that their team activities will have developed, and allow them to go on exercising their creativity and ingenuity and build up even stronger emotional bonds with their colleagues and a solid sense of commitment to their workplace and the work they do there.

They should no longer rely on external inputs but be totally autonomous and independent, drawing on their own resources to drive their actions, and fully capable of making the required contribution to the company’s policy and objectives on their own.

Workflow for Step 7 (Full Self-Management)

- To consolidate the changes made to equipment and people, and the results achieved, and build a self-managing system in which operators take the initiative, ceaselessly striving to improve.

- To have everyone participate actively in a relentless drive towards zero failures, zero defects, and ‘management at the source’.

Step 7 Outline

Adopt the right approach to work

- Everyone must participate fully.

- They must know how their work is progressing and what results it is producing.

- They must be helped to feel a sense of achievement about what they have accomplished.

- They must be helped to develop into individuals worthy of recognition, and actually be given that recognition.

Basic Approach to Achieving a Self-Managing Workplace

Example of Self-Management Level Assessment