Autonomous Maintenance

Equipment Effectiveness

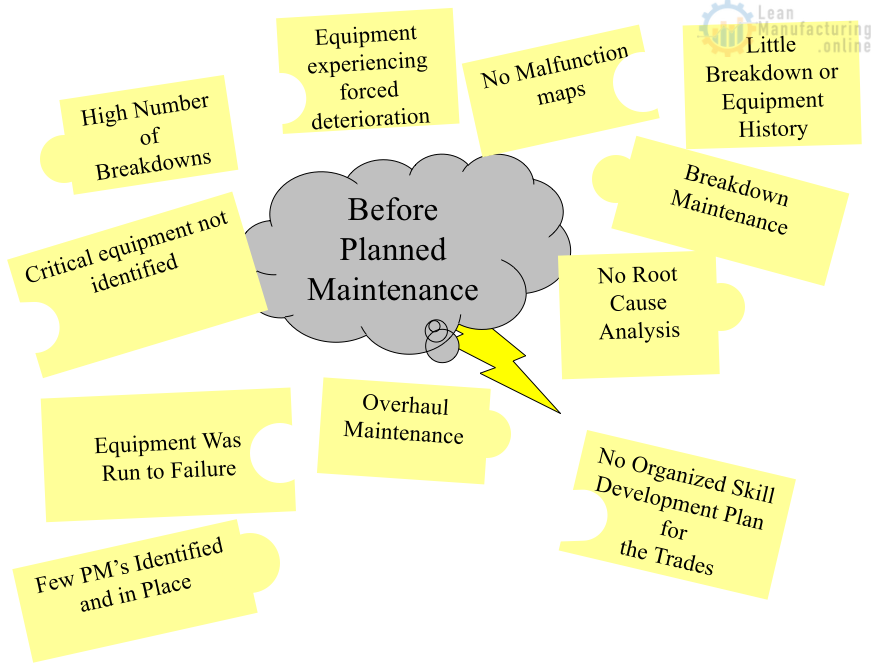

7 Step Activities of Planned Maintenance Full support of autonomous maintenance Restore Critical Equipment to Basic Condition Implement Corrective Maintenance activities Expose departments to MP activities Expand Predictive Maintenance activities Image 7 steps down below illustrates the relationship between the 4 phases for attaining zero failures and how they are subdivided into the…

Read More »Detailed Autonomous Maintenance Plan

Effectively and efficiently employ machinery, materials and manpower through the use of TPM tools. AM Step 0 LINK 1 Train or Refresh members on Step 0 ET 2 Train or Refresh members on LOTOTO ET 3 Personal Protective Equipment Identified and trained SHE 4 Principle of operation of machine understood…

Read More »Instructor Education Practical Training Manual – Autonomous Maintenance

Purposes and cautions of practical training for autonomous maintenance * The purpose of practical training is to master steps 1 through 3 of autonomous maintenance by experiencing them. * The purpose of autonomous maintenance is to improve the “work site.” The activity board of autonomous maintenance is just a tool.…

Read More »Autonomous Maintenance (AM) Pillar

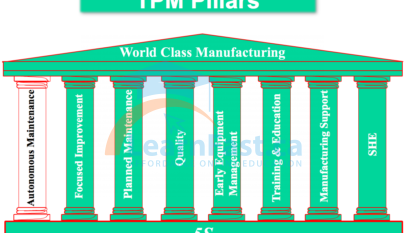

1. AM is The Culture Change Pillar. Poor AM implementation will inhibit the successful sustained implementation of TPM. 2. TPM is related to people, not only machines. The fundamental cultural / behavioral change of the TPM AM Pillar requires a real commitment to training and education. 3. It is…

Read More »