Focused Improvement

Principle of Operation – Analysis Diagram

One of the important steps to identify the Root Cause is an understanding of the process and equipment. To start, create a sketch of the machine or component, where you saw the problem occurred. The second step is to identify the Ideal Sequence of Movement, e.g. Pickoff arms move up->Solenoid…

Read More »What are One Point Lessons?

One Point Lesson is a short descriptive document to deliver fast communication to the team.

Read More »Deep Kaizen for Minor Stops – 7 Step Kaizen

How is a Minor Stop Defined? A machine stoppage is called a ‘minor stop’ when: the machine stops working for a short time; the machine can easily be restarted by removing or repositioning a workpiece; the machine can be restarted within a few seconds or minutes. The losses due to…

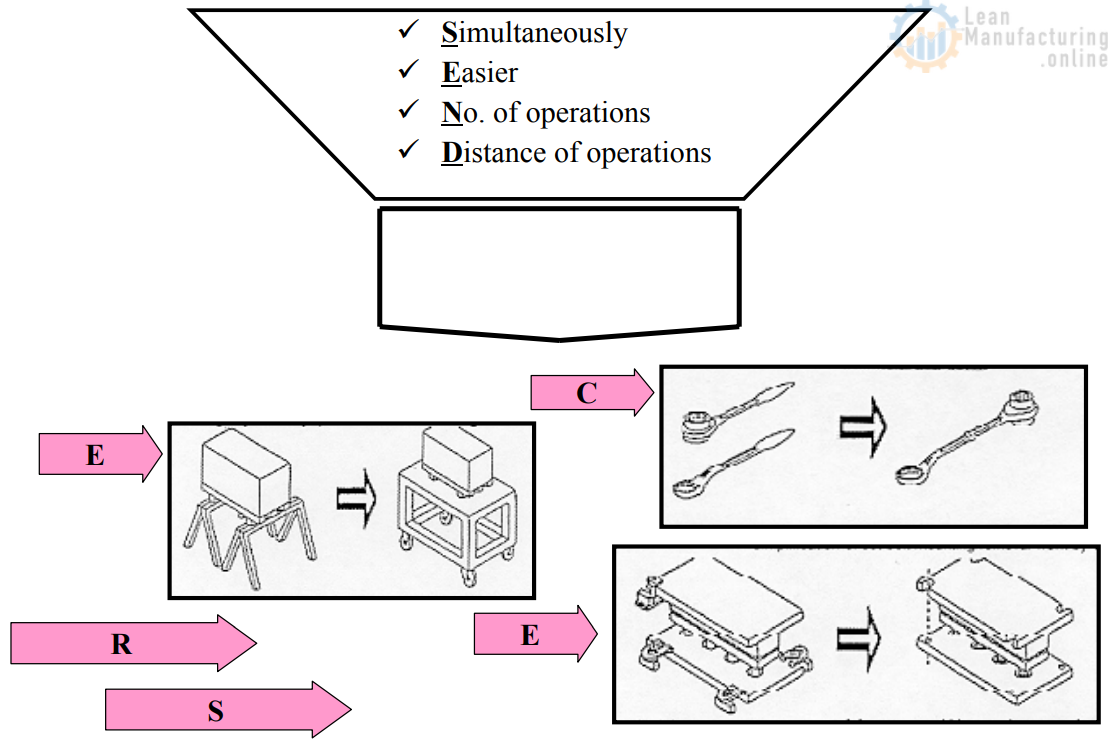

Read More »RFT (Right First Time) Changeover Kaizen, Beyond SMED (Single Minute Exchange Die)

What “Right First Time Changeover” means? RFT Changeover The structure of Changeover operations Preparation; Operations to bring and to look for hand-tools, jigs, all tools for changeover and include material loading & unloading operations. Setup; Operations to exchange jigs, guides, etc. from one thing to another. Adjustment; Trial-and-error operations to…

Read More »