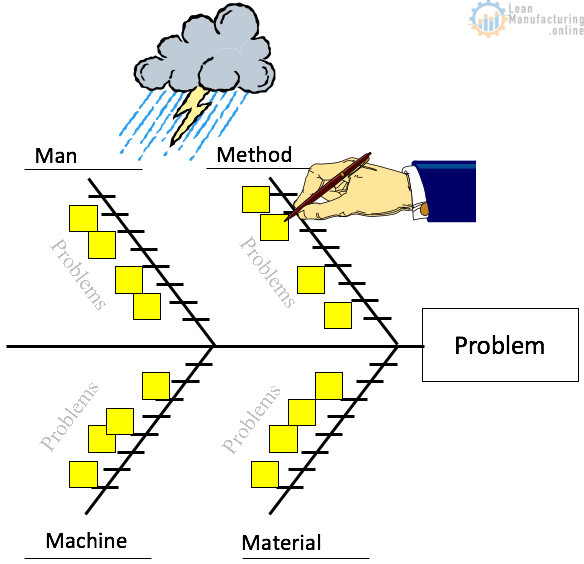

One of the important steps to identify the Root Cause is an understanding of the process and equipment.

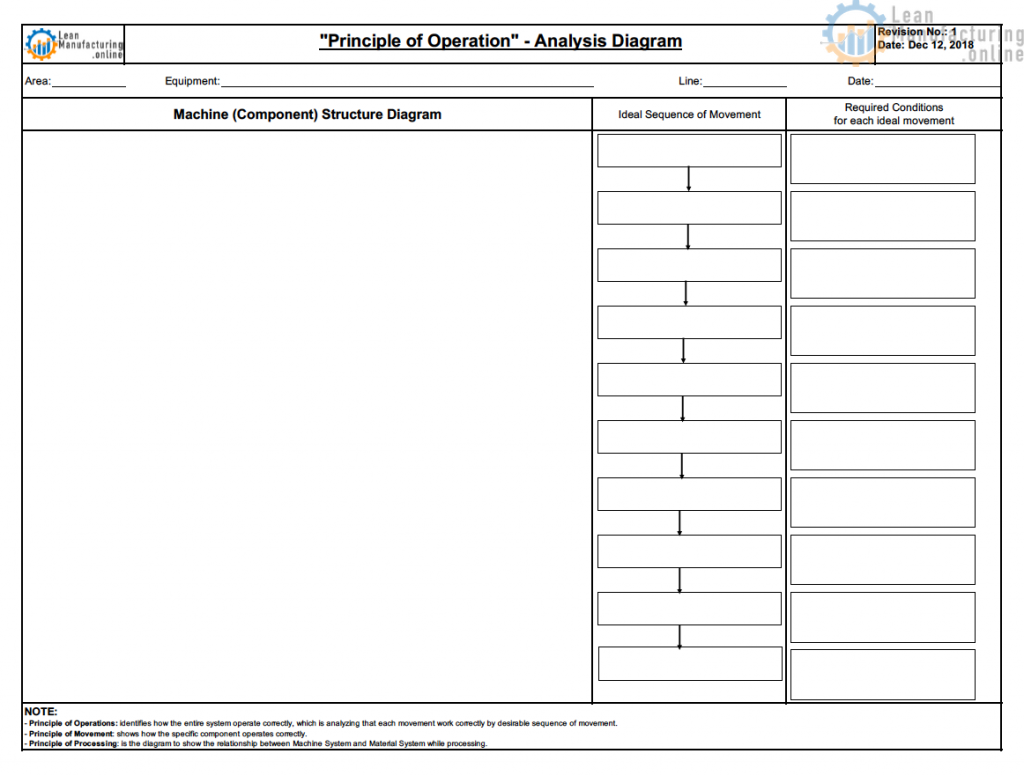

To start, create a sketch of the machine or component, where you saw the problem occurred. The second step is to identify the Ideal Sequence of Movement, e.g. Pickoff arms move up->Solenoid switching vacuum on->Created suction pulls carton from magazine->Arm moves down and inserts carton into flight chain… The next step is to capture Required Conditions for each ideal movement, e.g. Pneumatic cylinder needs to extend in order to move pickoff arm-Vacuum pump need to be running when the solenoid is switching vacuum on-magazine should have enough cartons…

- Principle of Operations: identifies how the entire system operate correctly, which is analyzing that each movement work correctly by desirable sequence of movement.

- Principle of Movement: shows how the specific component operates correctly.

- Principle of Processing: is the diagram to show the relationship between Machine System and Material System while processing.

We developed a form to capture Principles of Operation, down below you can download a .pdf form:

Download template here

This form can be used when implementing Step 3 of 12 Step Kaizen. or any other Root Cause based methods.