Instructor Training

Chapter 12. Completing and Upgrading the TPM Programme (Levels 1, 2 and 3). Part 2

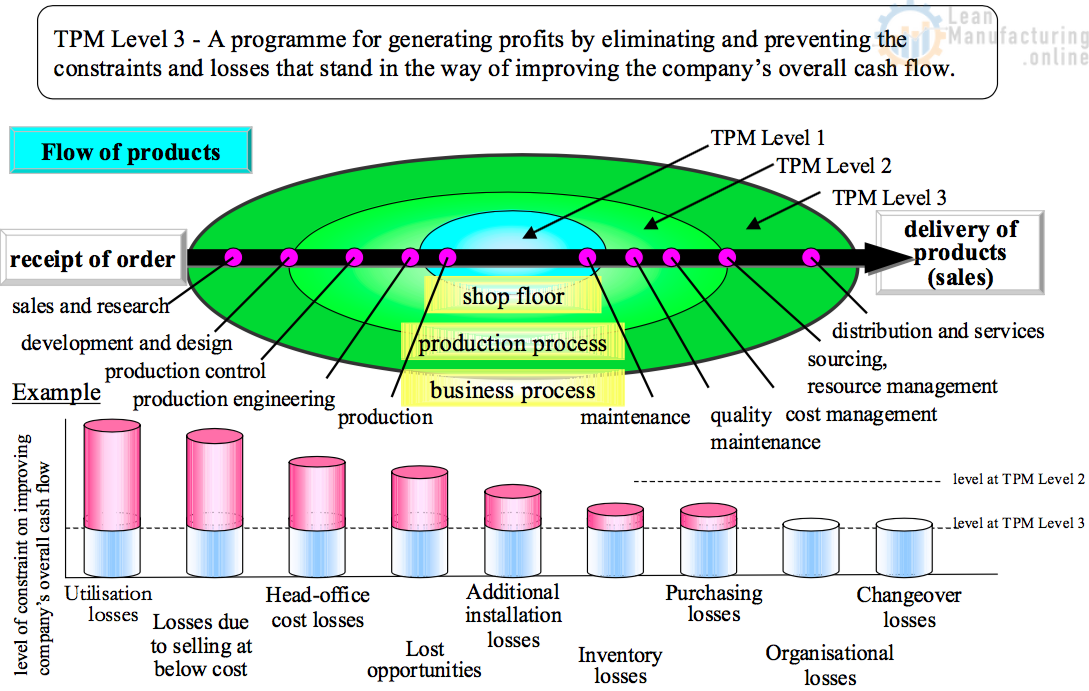

4 TPM Level 3 4.1 The Concept of TPM Level 3 – Improving Cash Flow As explained in the previous section, in TPM Level 2, we try to achieve the paradigm shift from ‘selling whatever we can make’ to ‘making only what we can sell’. The precondition for this is…

Read More »Chapter 11. Safety, Health and Environment. Part 3

Zero trapping or catching 1 Definition: A body part getting crushed, twisted, etc. by being trapped between objects 2 In broad terms, there are two types of trapping incident: – Caused by own actions, e.g. operator gets hand trapped when trying to wipe dirt off a moving roller. -Caused by…

Read More »Chapter 11. Safety, Health and Environment. Part 2

2.8 Using Safety Tags and Maps (1) Safety tags If an on-site safety inspection reveals a hazard, but nothing is done about it, the inspection will have served no purpose. Also, if the hazard is not clearly indicated, a person doing a safety check at a later date will not…

Read More »Chapter 11. Safety, Health and Environment. Part 1

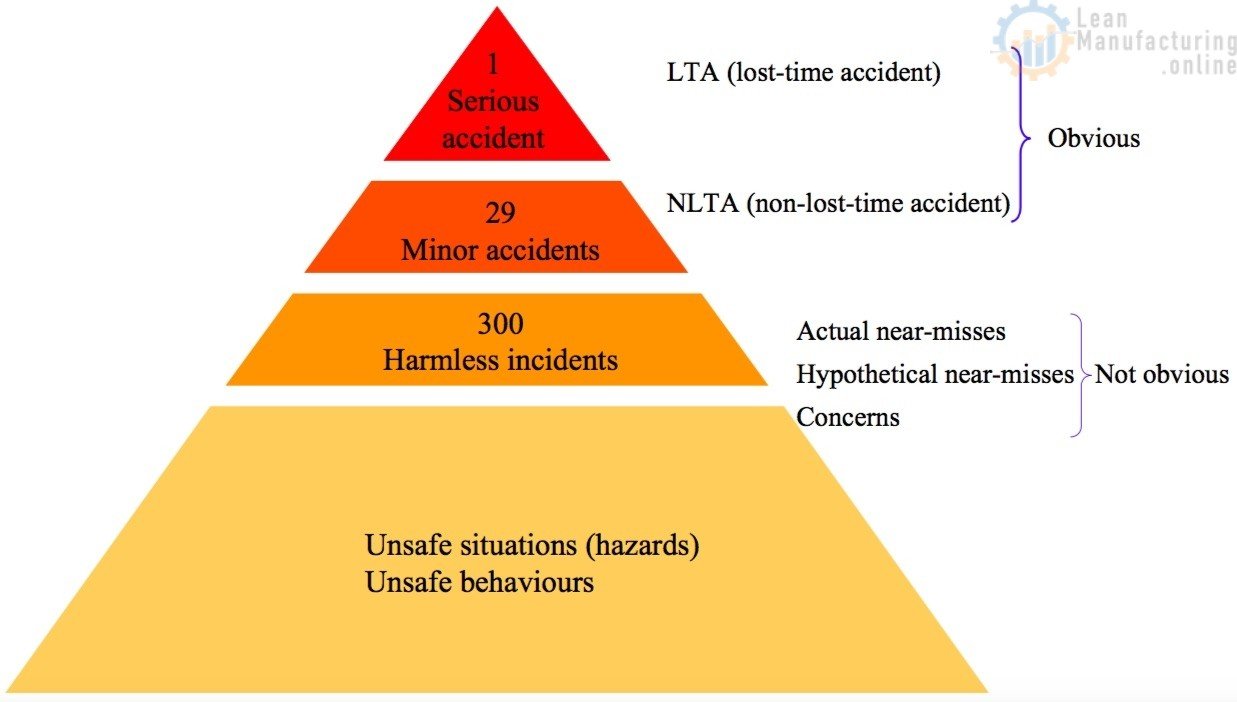

1. The Importance of Safety, Health and the Environment 1.1 An Overview of SHE The particular activities undertaken within a SHE programme will depend to a great extent on the prevailing attitudes toward safety, health and the environment in the company and the local community. Because of this, TPM does…

Read More »