Zero trapping or catching

1 Definition: A body part getting crushed, twisted, etc. by being trapped between objects

2 In broad terms, there are two types of trapping incident:

– Caused by own actions, e.g. operator gets hand trapped when trying to wipe dirt off a moving roller.

-Caused by other factors, e.g. getting trapped unexpectedly by an automatic robot, or accidentally trapping someone else who was standing behind the equipment without the operator knowing.

In either of these cases, a trapping accident occurs because a person comes into contact with a danger source. So, the first thing to do is to find all the places where trapping may possibly occur in the workplace. Typical examples include:

- Operating ranges of pneumatic and hydraulic machinery

- Exposed parts of rotary equipment

- Operating ranges of robots

The identified points are then marked on a map. Also, if a piece of equipment has a guard, but it is not really adequate, then that point must go down on the map as well. A list of checkpoints is indicated below.

(2) List of checkpoints (example)

(3) Finding countermeasures

Safety countermeasures can be designed from various perspectives:

1 The machinery is halted if someone accidentally (or deliberately) enters a danger zone.

- The machine stops if a barrier is opened

- The device is fitted with a safety interlock

2 People are kept away from the danger source by barriers, etc.

-

- Barriers should be designed not to impede inspection, cleaning, lubrication, etc., and transparent panels should be fitted to aid inspection.

- The barrier rails should be set a suitable distance apart.

3 Warning signs are affixed, or warning devices installed, to alert personnel to

dangerous situations

Some examples of warning signs are shown below. If the process of introducing appropriate safety measures is going to take time, then your immediate priorities should be to clearly indicate all hazard zones, and install protective barriers, so that operators do not come into contact with danger sources.

Zero falls (falling over, falling from a height)

1 Definition : Falling from a height: An operator falls off a machine, ladder, step, etc. Tripping: An operator trips over on a virtually level surface

2 The following list of checkpoints relating to falls from a height can be used to check the safety situation in your workplace:

|

Passageways, stairs |

|

|

Are there safe passageways? |

|

|

Are these passageways fitted with rails? |

|

|

Do the rails comply with the standards? |

|

|

Are the floors of the passageways corroded or deformed in any way? |

|

|

Are there steps and stairways that allow high and low areas to be reached safely? |

|

|

Are the stairway steps designed suitably? |

|

|

Are the stairways fitted properly with handrails? |

|

|

Do people hold the handrails and make sure their footing is secure when they go up or down stairways or along elevated walkways? |

|

|

Are openings fitted with guards? |

|

|

Are manholes, pits, etc. indicated by suitable hazard markings? |

|

|

Are any fittings loose or damaged? |

|

|

Ladders, stepladders, etc. (except for engineering work) |

|

|

Are ladders free from corrosion and damage? |

|

|

Are ladders firmly fixed, so that they do not slip or move in any way? |

|

|

Do any operators carry loads up or down steps, ladders, etc., so they cannot hold onto the handrails? |

|

|

Ladders must not be erected on uneven or soft floors. |

|

|

Never stand on the top step of a stepladder. |

|

|

Are the anti-splay restraints on stepladders working properly and undamaged? Ladders and stepladders must only be used by one person at a time. |

|

|

Inspection work at heights (except for engineering work) |

|

|

Has it been made obligatory to wear a safety harness whenever working at a height of over 1.8 m above floor level? |

|

|

Are rails or ropes provided for clipping the safety harnesses onto? |

|

|

Workplace |

|

|

Is the floor even and free of changes in level? |

|

|

Are there any slippery areas or areas where workers have slipped in the past? |

|

|

Are there any areas that are not sufficiently illuminated? |

When seeking to prevent operators from falling over in the horizontal plane, it is important to learn from any near misses that the employees may have had, as well as checking the points listed below: |

3 When seeking to prevent operators from falling over in the horizontal plane, it is important to learn from any near misses that the employees may have had, as well as checking the points listed below:

|

Is the floor smooth, even and free of changes in level? |

|

Are there any areas where oil or water has collected? |

|

Do the operators have dirt on their shoes? |

4 Mark danger points on map

The dangerous areas identified in step 3) should be drawn on a map of the workplace.

5 Create improvement plan

Determine an order of priority for the points that need to be improved, based on the seriousness of the injury that would result if the envisaged accident actually occurred, and the frequency with which operators visit the location. Improvements to rectify these dangers should then be carried out in a planned and systematic way. If there are any problems that cannot be resolved straight away, then action must be taken to mark these clearly and boldly, so that workers know where the danger points are and understand the correct working procedures to follow.

Zero cuts and bruises

1 Definition: Colliding with a stationary or moving object

2 Checkpoints (example)

|

Passageways |

|

|

Is there any point where someone might bump their head? |

|

|

Are there any projecting parts that people could strike themselves against? |

|

|

Are there any doors that could hit someone if opened suddenly? |

|

|

Are there any sharp objects? |

|

|

Storage of pallets, etc |

|

|

Have limits been set for the number of pallets that can be stacked on each other? |

|

|

Are these limits being observed? |

|

|

Are the pallets being kept to their designated storage positions? |

|

Zero burns

1 Definition: A burn caused by touching a hot or very cold object

2 Temperature and burns

There are basically three ways that a person can make contact with a hot object:

– Touching a fixed hot object, such as a hot part of a machine, etc.

– Touching a hot object while handling it, e.g. during gas welding, working with a cutting torch, etc.

– Coming into contact with the hot contents of a pipe or other vessel if it bursts, when stripping it down to inspect it, etc.

3 Fixed high-temperature parts of machinery are usually covered with thermal insulating material, but the workplace must be checked to see if it contains any of the following:

|

Hot spots on motors and drive systems |

|

Hot spots on hydraulic pipes |

|

Hot spots on reactors |

If there is any possibility of an operator coming into contact with points like these, then the following items must be checked:

|

Is a suitable safety barrier or safety cover fitted? |

|

Is the safety barrier or safety cover designed so that a person will not come into contact with the heat source, even if they handle it in the wrong way? |

|

Is the heat source covered with thermal insulating material? |

|

Is the insulating material broken, damaged or loose? |

|

Are there suitable ‘Caution! HOT!’ warning signs? |

If welding or cutting operations using naked flames are carried out in the workplace, then it should be confirmed that there are proper work standards in place, and that these standards contain all the necessary precautionary information.

4 Examples of countermeasures

Thermal insulating material is usually placed over hot parts in order to prevent their temperature from dropping, but any uncovered parts should be protected by guard rails. Also, if there is a possibility that an electric motor, etc., may get hot, then a thermosensitive label should be applied to it, so that any temperature rise can be spotted straight away.

Zero electric shocks

1 Definition : When someone receives a shock by touching part of their body against a live conductor

2 Electricity is invisible, so it is impossible to tell where and when it is flowing. Therefore, although the following points must be inspected with the power supply turned off, they must never be touched whilst the equipment is running, even if a problem is detected. Particular care must be taken to avoid electric shocks caused by inadvertently touching a part through which a leakage current is passing.

Electrical work must only be carried out by properly qualified personnel. Always contact a specialist electrician for this kind of work.

3 Inspecting electrical equipment

Carry out the following visual checks:

|

Is all arc welding equipment properly fitted with an automatic shock-protection device? |

|

Are any cables for power tools, etc. damaged in any way? Are the conductor wires exposed? |

|

Is equipment earthed? Are the earth wires connected correctly? |

|

Are any cables to power sockets damaged? Are the conductor wires exposed? |

|

Are any electric motors or other electrical equipment exposed to water? |

|

Are the lids fitted properly on the distributor boxes? |

|

Do the switchboards have openable lids, and are they usually kept closed? |

|

Are electric motors and other electrical devices provided with earth connections, and have any of the earth wires come loose? |

|

Is there rubbing or damage to any of the wiring? |

Strategies for dealing with points that are difficult to resolve

Up to now, we have been considering the points that should be checked in order to avoid different types of accident, such as trapping or catching, falling, cuts and bruises, burns, and electric shocks. However, the main aim should always be to build in intrinsic safety by implementing physical countermeasures wherever possible. If no immediate countermeasure can be devised, then the potential hazard must be clearly indicated to everyone on the shop floor, by installing signs or indicator boards, etc. stating the work details, the established procedure, and precautionary information. The following types of warning can be used:

- Operational indicators

This type of indicator shows the operational state of the equipment, such as ‘Operating’ or ‘Standby’, as well as marking the position of emergency stop buttons. These indicators should be readily visible from any angle, and may consist of lamps, etc. fitted to the equipment. - Indicators marking danger zones, high-voltage parts, harmful substances, dangerous objects, etc.

- Warning signs

Warning signs, such as ‘Caution! Rotating Parts!’, ‘Gloves Prohibited!’, ‘Mind Your Head!’, and so forth, alert the operator to potential dangers, and state clearly what he or she must be careful about. This helps to raise safety awareness in the workplace.

Establishing and consolidating the safety management system

The equipment and personnel in the workplace are always changing, sometimes gradually, and sometimes very suddenly. Great pains may be taken to implement improvement proposals and conform to established rules and procedures, but if these are not monitored continuously, the improvements will soon come unstuck, and before it knows it, the company will be back where it started . If safe conditions are to be maintained over the long run, then it is vital that changes of this kind are detected early on, so that swift action can be taken in response. For this purpose, a system is needed to keep the safety PDCA cycle revolving at the company level.

(1) Consolidating the safety organisation

A dedicated organisation must be set up in order to ensure that safety activities are implemented smoothly, across the board. The main objectives of such an organisation are:

- Detect problems in the workplace swiftly and accurately, and devise suitable countermeasures.

- Formulate annual policy and month-by-month plans, and ensure that the workforce knows about them.

- Collect information on the current safety situation in the workplace.

- Investigate possible countermeasures suited to the safety situation, and decide on measures to be adopted.

To achieve these objectives, a system of regular meetings is set up, and suitable people are selected to attend those meetings and discuss safety issues.

(Example of meetings)

- Health and Safety Committee / Section Safety Committee / Group Safety Committee / Safety Planning Committee

(2) Formulating a safety policy and action plan

As well as setting up a management structure, a clear safety policy and action plans should be drawn up, and behavioural guidelines detailed for all personnel, so that everyone can pull together towards achieving a safe workplace. At the same time, company slogans and departmental slogans should be devised, along with other ways of ensuring that the activities have a common focus.

(3) Workplace safety assessments by safety patrols

Safety patrol teams visit the actual workplace to observe the state of the equipment and the work environment. Their aim is to check how effectively safety measures are being implemented on the shop floor, and how rigorously the established procedures are being followed. Patrol teams may be made up of managers only, or a mixed group of managers and shop-floor representatives, and they should patrol regularly, while operators carry out their own routine inspections. These patrols are much more than a casual ‘once-over’ of the shop floor. Each patrol team must prepare a comprehensive checklist focusing on its own particular angle, and every effort must be made to ensure that a really effective regime of patrols and self-inspection is achieved and the actual safety situation is identified accurately.

Creating workplace safety inspection standards and implementing and recording rules and procedures

The procedures and minimum rules of good conduct determined in the activities described above must be observed scrupulously by everyone. Any areas or particular tasks where these rules cannot be strictly adhered to should be identified. If safety is to be maintained, it is important to establish rules (safety inspection standards) stipulating how to comply with established procedures. At the same time, a record must be kept of the safety situation. Some inspection points can be assessed on a basic pass/fail system, whereas others will need to be measured. It is essential to record the results of inspections carefully so that the safety situation in the workplace can be closely monitored and controlled. This archive of information will prove invaluable in determining the causes of an accident, if one unfortunately occurs. There are also statutory requirements to be complied with, whereby companies must select the relevant inspection items and create a safety log, which is updated after each inspection. The 5W1H approach should be adopted when creating this inspection log.

Establishing emergency response systems

Although safety management focuses primarily on preventing accidents, emergency response systems must also be established in case an accident does happen. The following points, amongst others, must be decided and displayed in prominent positions in the workplace:

- Network of emergency contacts

- Standard procedures for calling out emergency vehicles

- Workplace preservation procedures and first aid for the injured

Preparing for and implementing safety awareness activities

Safety awareness activities should be conducted with the aim of getting shop-floor workers to spot the ‘seeds’ of potential safety problems, so that they can be dealt with before any danger actually arises. Near-miss reporting is also used to the same end. As the Heinrich principle tells us, accidents happen when the small seeds of danger are overlooked. To prevent accidents from occurring, the safety situation in the workplace must be continually assessed, by analysing near-misses and constantly seeking to identify anything that might conceivably lead to an accident. The hazards identified must be systematically eliminated, and similar measures applied to other relevant tasks, equipment or locations. These activities help operators develop a much keener awareness of potential hazards. The safety reports produced by these initiatives should be studied by managers every six months or so, to confirm how accurately the safety shortcomings have been analysed, and how effective the improvements have been.

Before developing these activities in the workplace, the managers themselves must first learn about safety awareness. Based on what they have learned, they can then draw up a format for the safety awareness initiatives, and put them into action on the shop floor, by giving appropriate instruction to the operators. Some other important initiatives that could be introduced in order to enhance safety awareness are: near-miss reporting systems, the ‘4 round method’ (a system developed by the Japan Industrial Safety and Health Association), and ‘touch and call’ routines (see below).

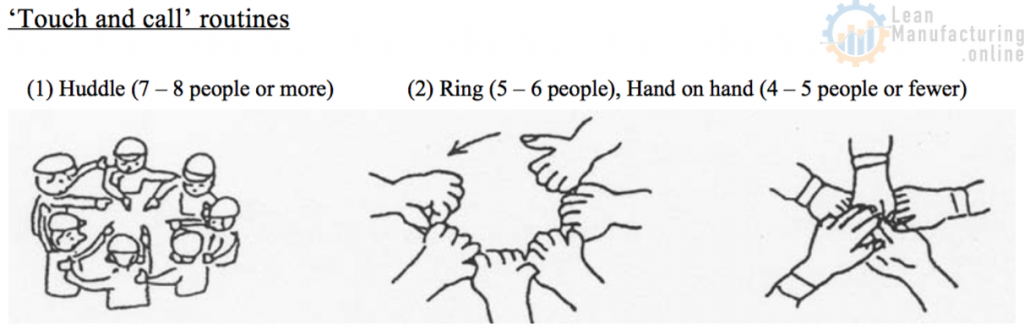

‘Touch and call’ routines

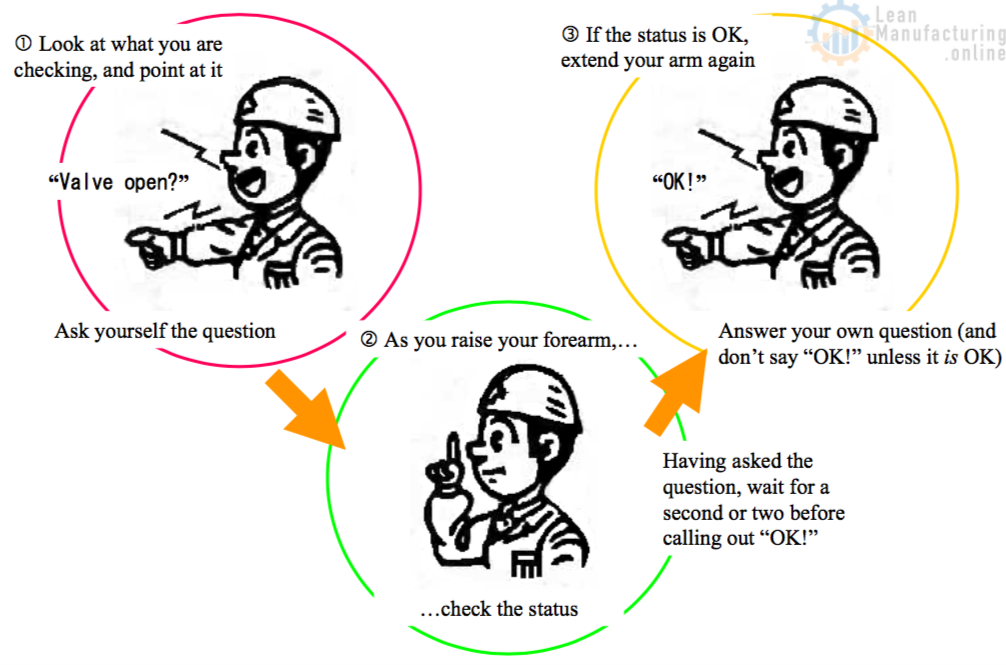

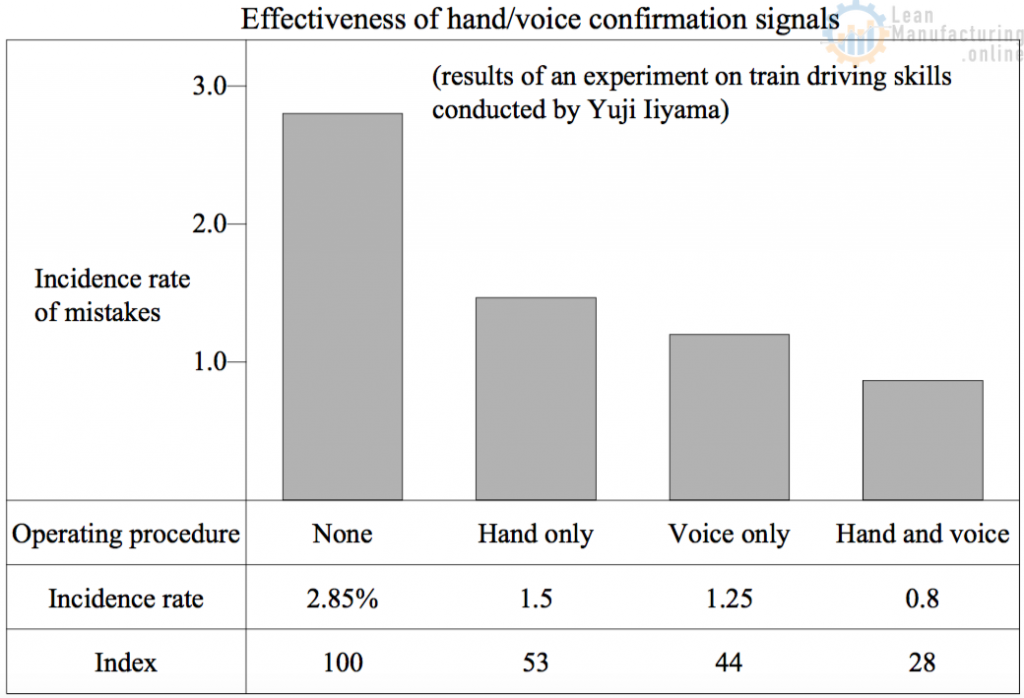

Hand/Voice confirmation signals (‘Point and Call’ routine)

At each crucial juncture of the task in hand, the operator looks squarely at whatever needs to be checked. Extending an arm and pointing a finger in the appropriate direction, he or she calls out the checks (“Left OK! Right OK! Front OK!” and so on). This ensures that the operator’s eyes, arm, finger, voice and ears are all fully mobilised in checking that his or her actions are correct and that everything is safe.

The procedure is as follows:

Eyes: Look carefully at whatever needs to be checked.

Voice: Call out each item to be checked, one by one (“Valve open? OK!” and so forth).

Ears: Listen carefully to your own voice.

Arm and fingers: Place the left hand on the waist, and extend the right arm with the index finger pointing towards whatever is being checked. Each time you call out the question part of a new check, bend your elbow, raising your index finger to ear height in a salute-like motion, and straighten your arm out again when you call out the “OK”. Extend your index finger, with the rest of your fingers balled into a loose fist.

Points to be reviewed in creating standards and maintaining and improving safety:

|

Is there a company-wide system of safety meetings? Are safety activities being monitored properly? |

|

Has a plan been devised for safety activities? Has it been communicated to each department and section? Do the safety activities throughout the company have a single, common focus? |

|

Have suitable slogans been created? |

|

Have patrols been set up, and are they being carried out systematically? |

|

Have safety standards been created, and are they being observed? |

|

Are safety awareness activities and near-miss identification activities being carried out consistently, on an ongoing basis? |

|

Is there a proper contact system in place in the event of an emergency? |

Reference 3

Reducing fatigue

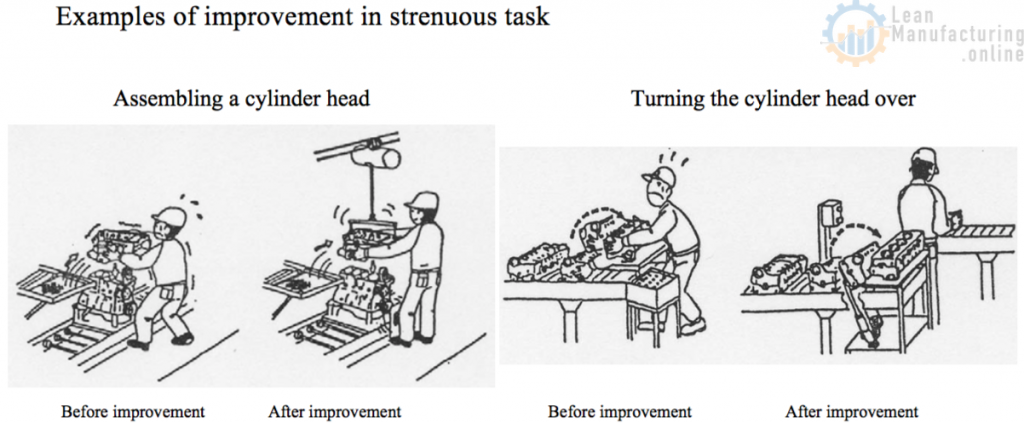

(1) There are two principal types of fatigue: mental and physical (2) Reducing physical (muscular) fatigue

-Reducing strenuous work

Handling heavy objects places significant physical stress on the operator,

whether when lifting objects and loading them onto a truck, for instance, or when

carrying them from place to place. -Improving the working posture

- Hard work – handling heavy objects + high-load working posture (no. of operations, continuous working time)

- Bending at waist, bending at knees and waist, twisting, stretching

- Bending of joints, use of muscles, energy use, difficult positions and loads

- Working postures with high load factor – hard work – poor image

(3) Reducing mental fatigue

When people have to perform monotonous surveillance work or jobs that require them to concentrate hard and make frequent decisions, they eventually become mentally tired and end up making mistakes or becoming less productive. Furthermore, when people get bored, they begin to feel tired as a reaction to the monotony. This fatigue produces a loss of mental sharpness, accompanied by a vague feeling of sleepiness and lack of concentration.

It is important to eliminate strenuous tasks and strained working postures from the workplace. This means devising optimal processing conditions that reduce heavy object handling, and eliminating difficult jobs that require operators to adopt an awkward posture. This is a key issue that must be positioned as part of the company’s basic philosophy and tackled within its Early Management programme, so that equipment and products are designed from the start to make assembly and manufacturing processes easier.

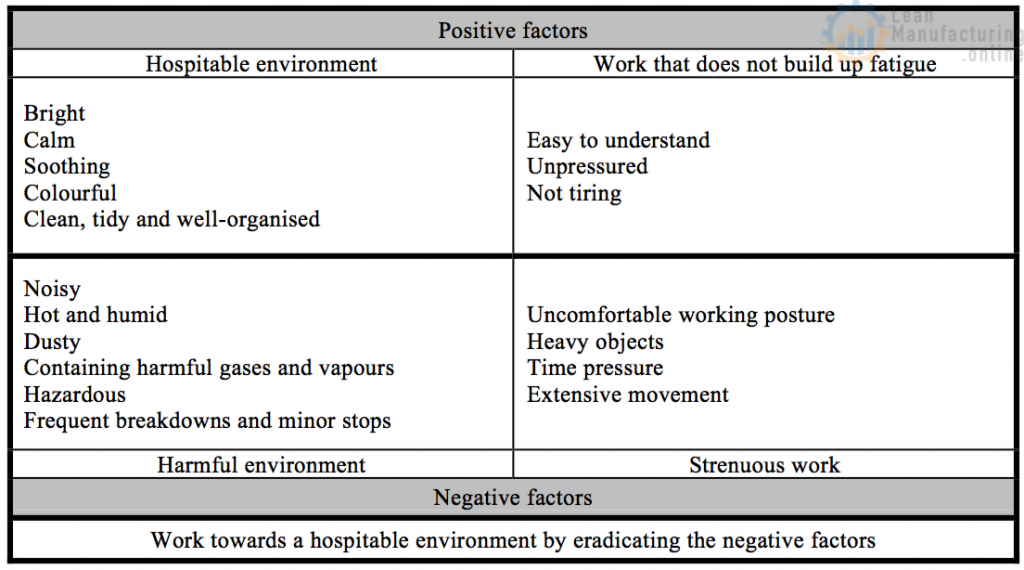

Achieving a hospitable work environment

(1) The following two conditions must be satisfied in order to achieve a work environment that allows employees to enjoy their work and stay in high spirits.

-

- The workplace environment itself must be hospitable

- The work must not cause fatigue to build up

(2) Concepts for creating a hospitable work environment

The first step towards creating a pleasant and agreeable working environment is to try to minimise the harmful negative factors and maximise the positive ones, by, for example:

- Eliminating noise, high temperatures, dust, and harmful gases and vapours

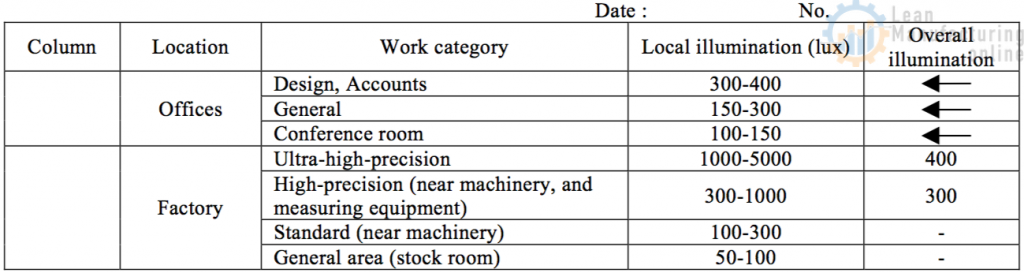

- Creating a well-lit, calm, relaxed environment

- Ensuring that work tasks do not create a build-up of fatigue

In pursuing these initiatives, management must always look to create a workplace that people will actually enjoy working in. If they do this, then the operators themselves are much more likely to pitch in and help to keep their work environment clean, tidy and well-organised and make it pleasant and worker-friendly.

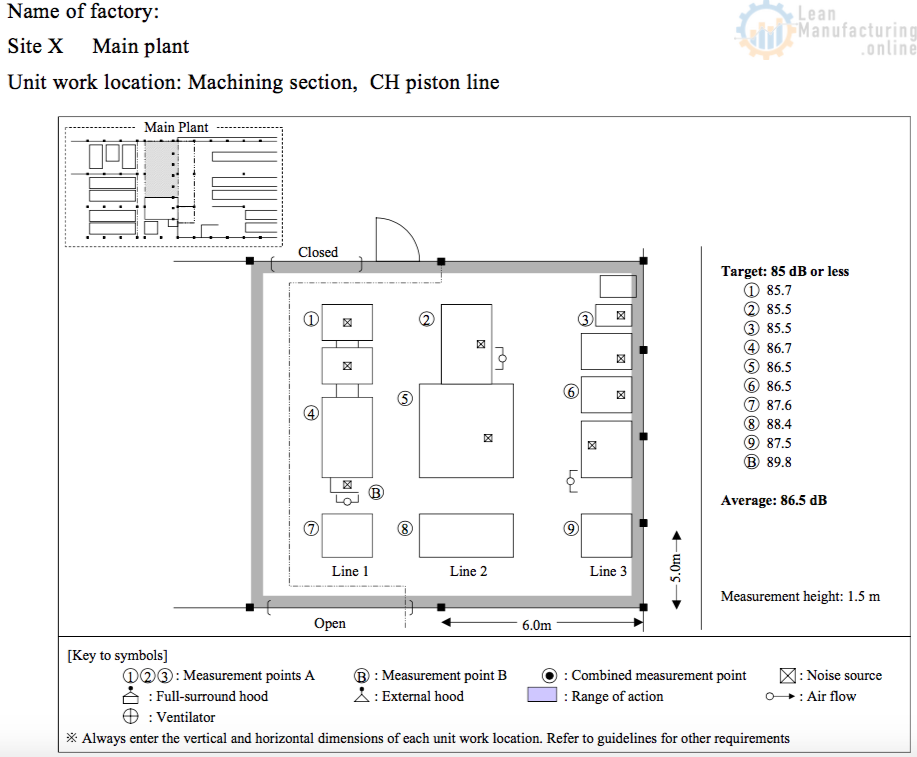

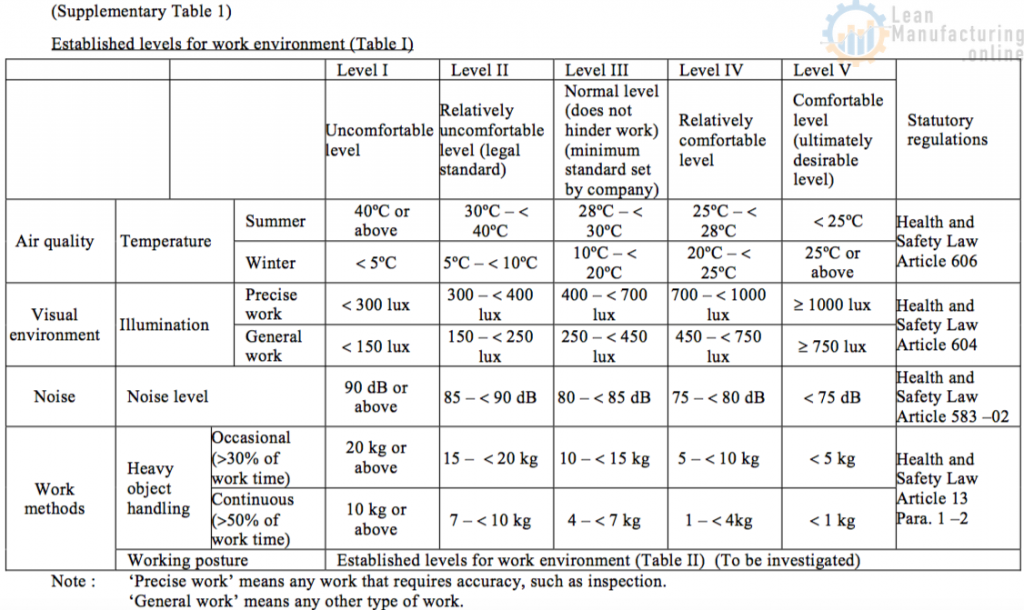

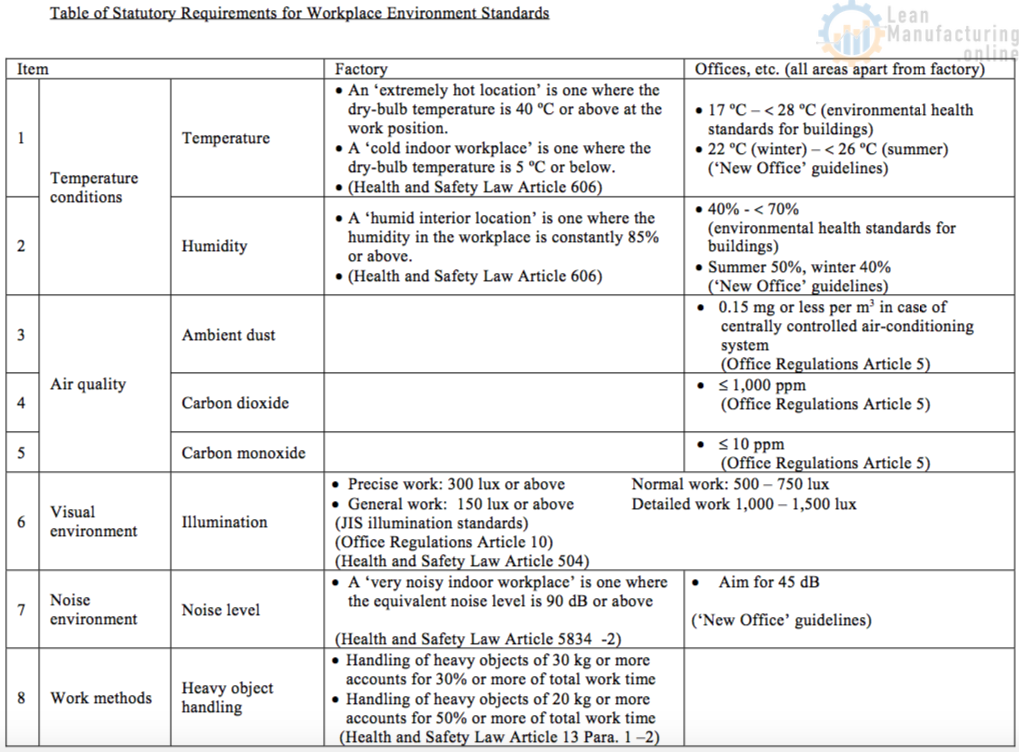

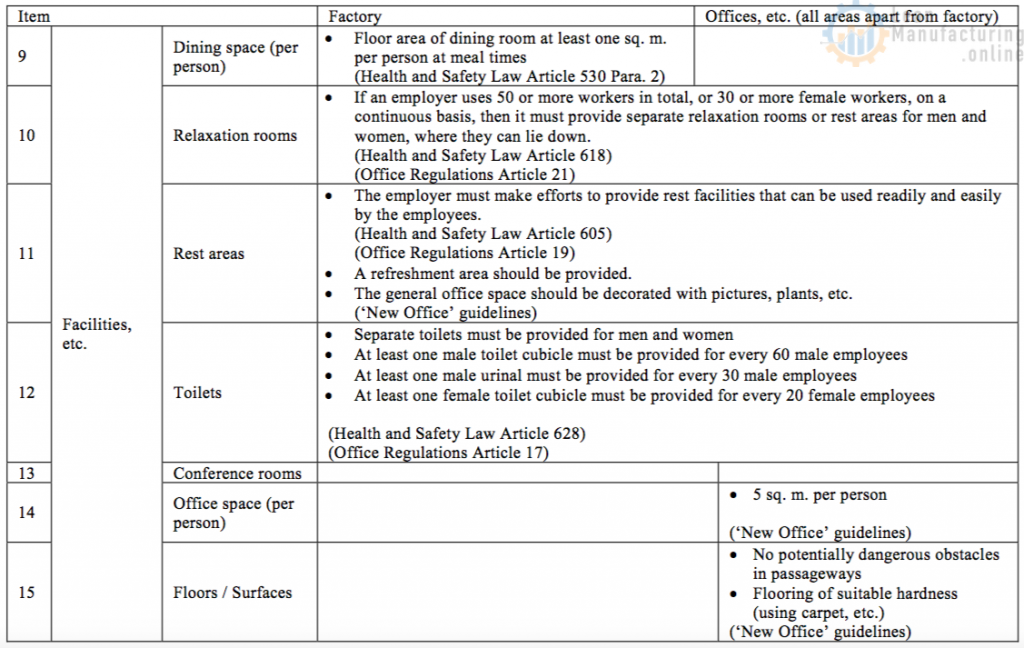

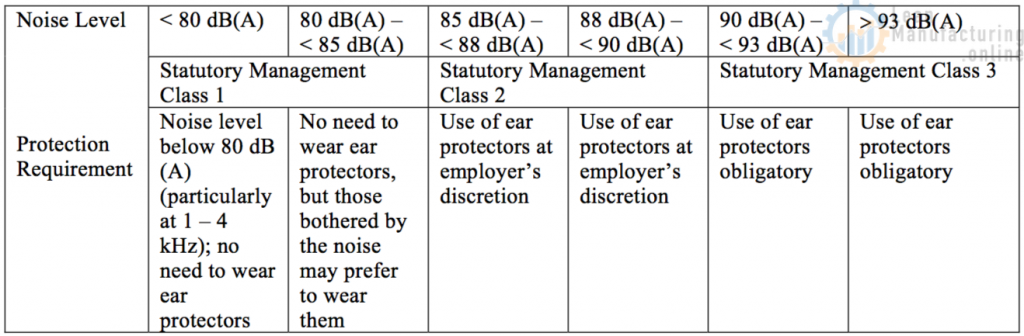

For each unit work location, indicate the boundaries, the main pieces of equipment, sources, measurement points, etc.

For each unit work location, indicate the boundaries, the main pieces of equipment, sources, measurement points, etc.