Planned Maintenance

Autonomous Maintenance Step 4 Case Study

Autonomous Maintenance Blog Education and Training Manufacturing Support Planned Maintenance Training World Class Manufacturing

Implementation Team Values: IntegrityDemand diversity of thought!Responsibility and accountabilityDefine & communicate roles, responsibilities, and actions plans for teams and individuals! 5W & 1H WHAT: Major Stoppages/BreakdownsWHEN: DailyWHERE: Packaging LinesWHO: MechanicWHICH: N/AHOW: Not Enough time to Eliminate SUMMARY OF PROBLEM:Mechanics do not have enough time to Eliminate Major Stoppages/Breakdowns that occur…

Read More »Troubleshooting packaging and processing equipment

One of the important tasks of Maintenance crew is quickly return equipment back to production after breakdown happens, so minor won’t become major one. Although analyzing breakdown and implementing countermeasures are necessary steps to improve OEE but also to have the best skill set to troubleshoot and repair is essential to…

Read More »Five Causes of Equipment Breakdowns

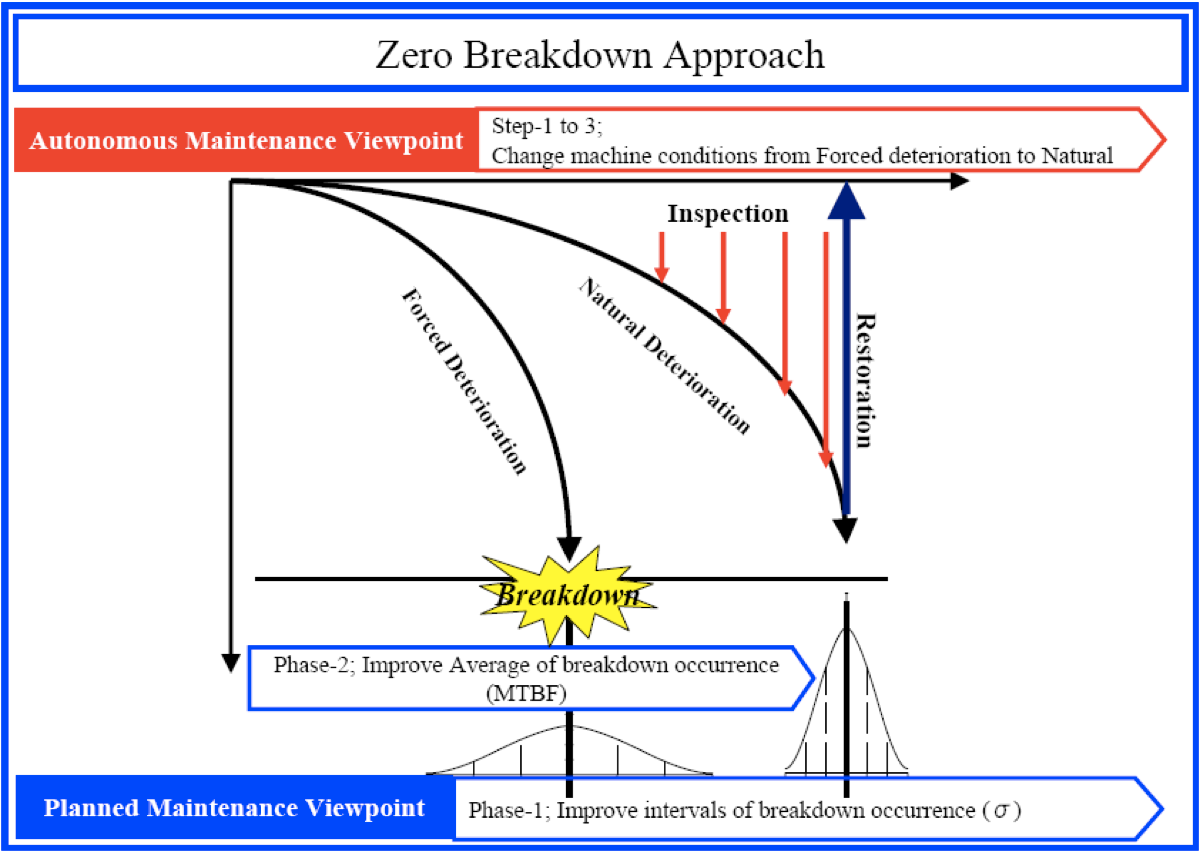

When equipment breaks down it is necessary to find root cause of the problem. Let’s review five main causes. Forced Deterioration These breakdowns are caused by: Lack of Cleaning (accumulation of Dirt and Dust);Lack of Inspection (e.g. loose nuts, bolts, etc);Lack of Lubrication. Lack of Basic Conditions (CIL) ! What…

Read More »Classification of Assets by Criticality

Classifying the Equipment by how critical they are to the process, allows the maintenance planners to better plan & schedule the work required. They can prioritize the work and attend to the most important equipment first, maximizing the available resources and increasing the effectiveness of the maintenance department. This classification…

Read More »