Planned Maintenance

Gap Analysis and General Findings of Effective Maintenance

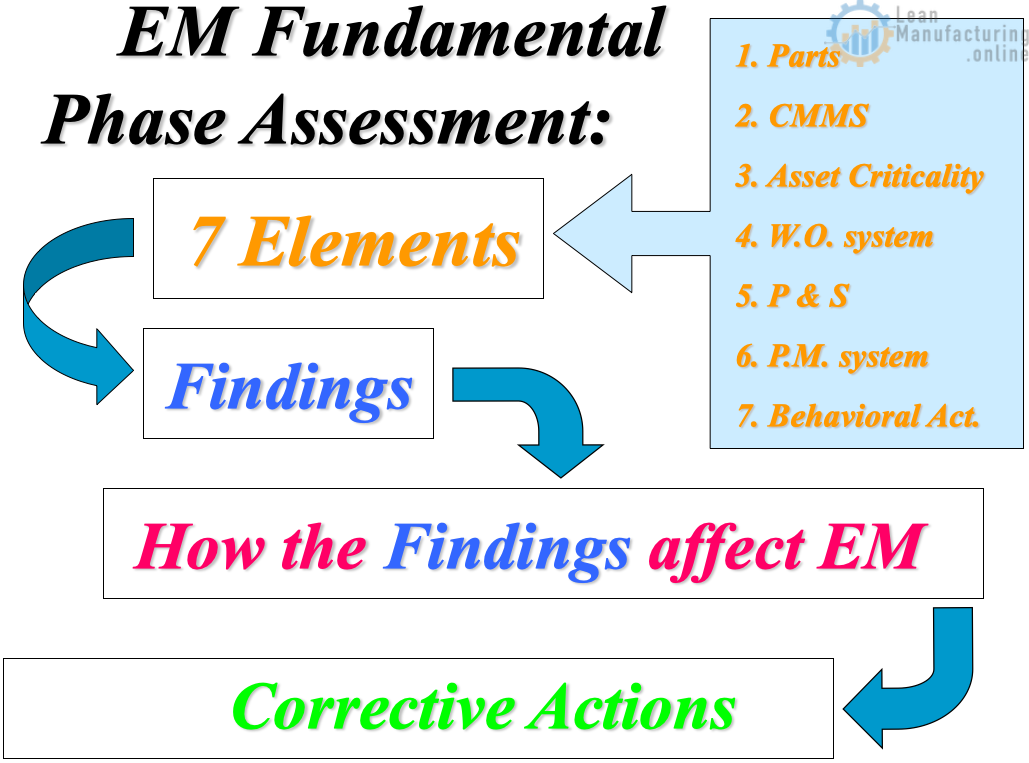

To perform gap analysis, relative rankings of different facilities (sites) need to be captured: Parts and Materials in Store Room Computerized Maintenance Management Software (CMMS) utilization Criticality of assets ranked and maintained Planning and Scheduled work Work order system Effectiveness of Preventative Program (PM) Maintenance Management Duties, Tactics and Best…

Read More »8 Elements Approach – Planned Maintenance Structure

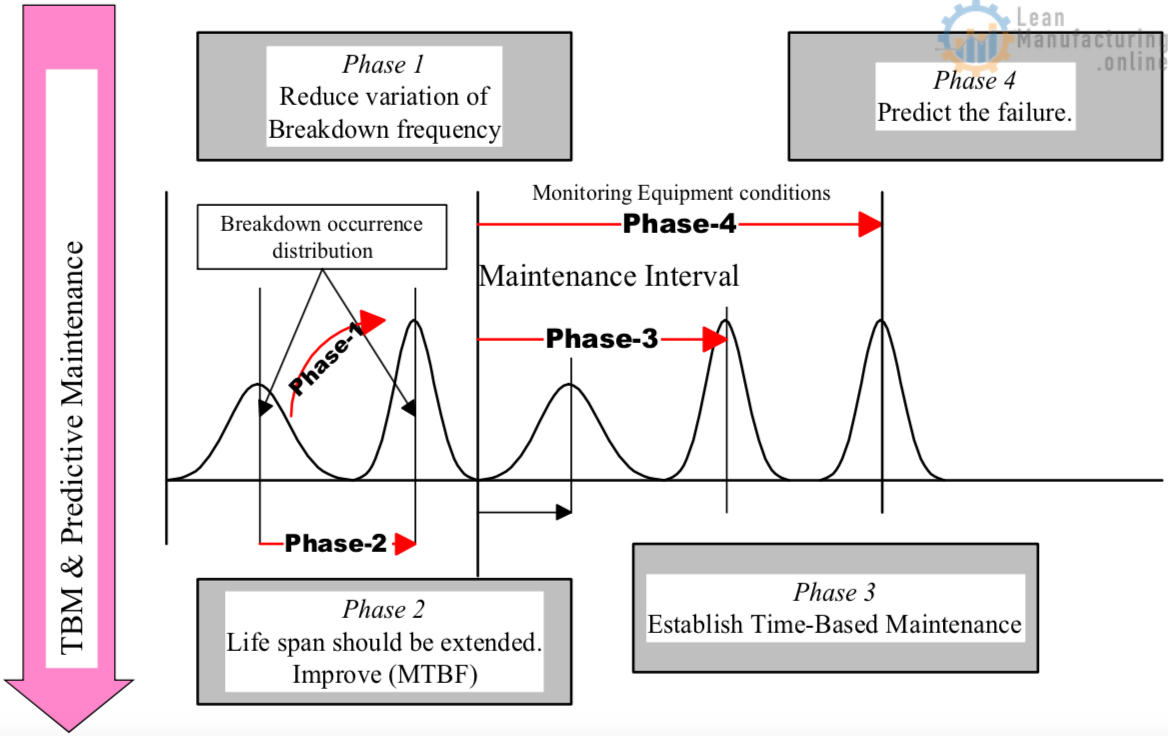

TPM activity in which the specialized maintenance department shifts the maintenance focus: from breakdown maintenance (BM) to preventive maintenance (PM) from corrective maintenance (CM) and time-based maintenance (TBM) to predictive maintenance (PdM) or condition-based maintenance (CBM) while reducing maintenance costs and supporting the Autonomous Maintenance program. Four phases approach for…

Read More »Workplace Electrical Safety – PM training

The Basics Electricity flows more easily through some materials than others. Conductor – substances that offer little resistance (metal, earth surface) Insulator – Substances that slow down or stop flow of electricity (glass, porcelain, wood) When a person receives an electrical shock, sometimes the electrical stimulation causes the muscles to…

Read More »Millwrights and Mechanics Guide. Drawing and Sketching. Part 1

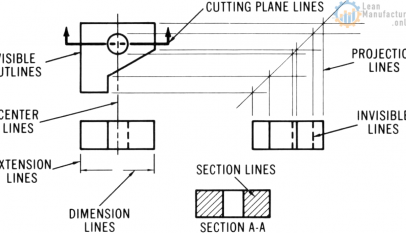

Drawings and sketches are universally used to communicate technical information. They are the graphic language used by everyone concerned with mechanical operations. They convey information, size, location, accuracy, etc.; and by their use, mechanisms ranging from the simple to the most complex can be graphically described. It is a universal…

Read More »