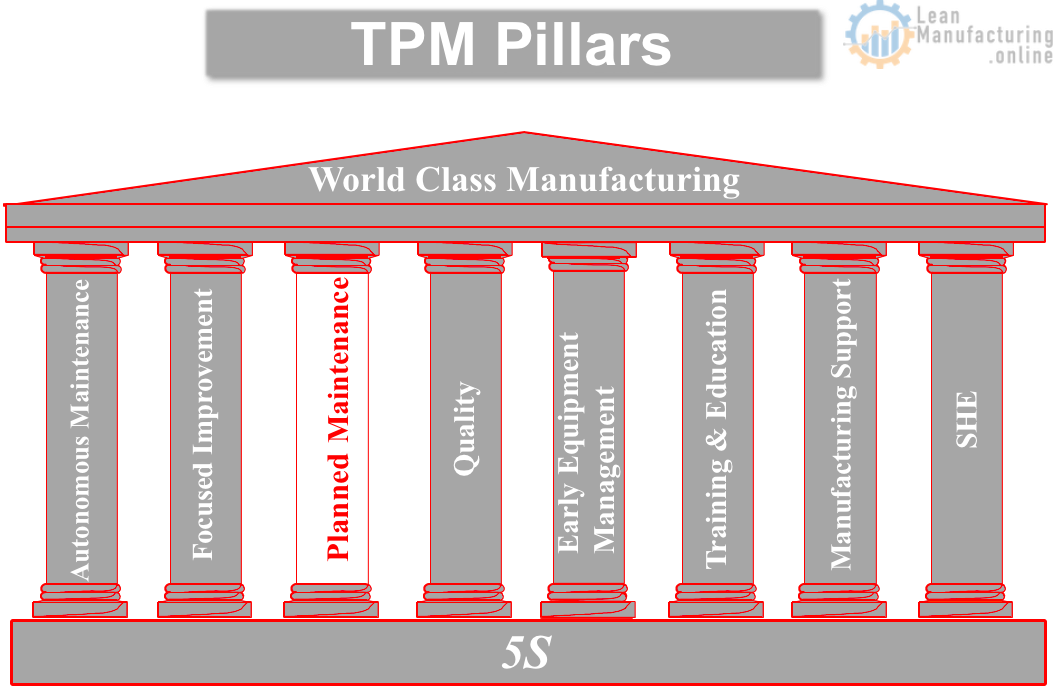

Planned Maintenance

Fundamental Phase Action Plan for Planned Maintenance Pillar

It is assumed that the PM lifelines in the Foundation Phase are already in place. This document details the elements of the Fundamental Phase. There are seven very distinct elements or clusters to put in place in the Fundamental Phase. The elements are in a natural “make sense” order; some…

Read More »Effective Maintenance Glossary

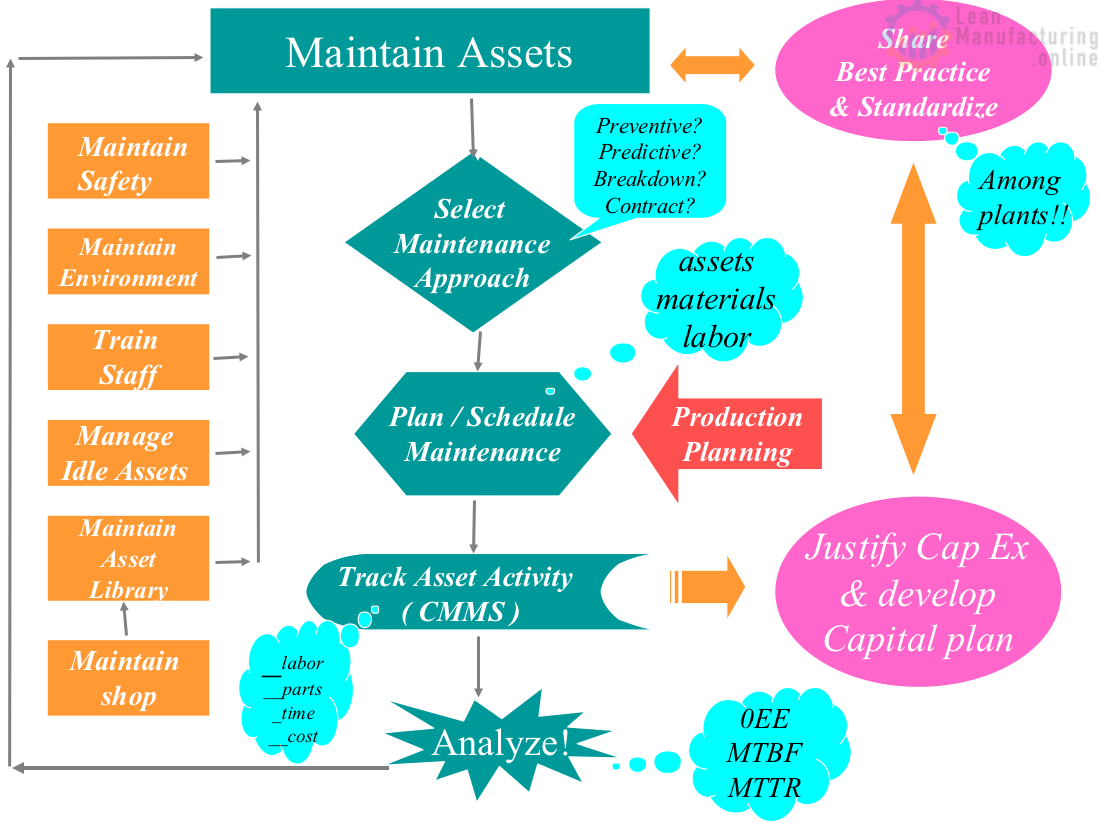

To identify and communicate a World Class Maintenance strategy, which maximizes asset life ensures consistently high levels of equipment safety and reliability, transfers basic Maintenance knowledge from Mechanics to Operators with the objective of improving conversion costs. ANNUAL PLAN It serves to formalize the planning process’ various outputs into one…

Read More »Equipment Effectiveness

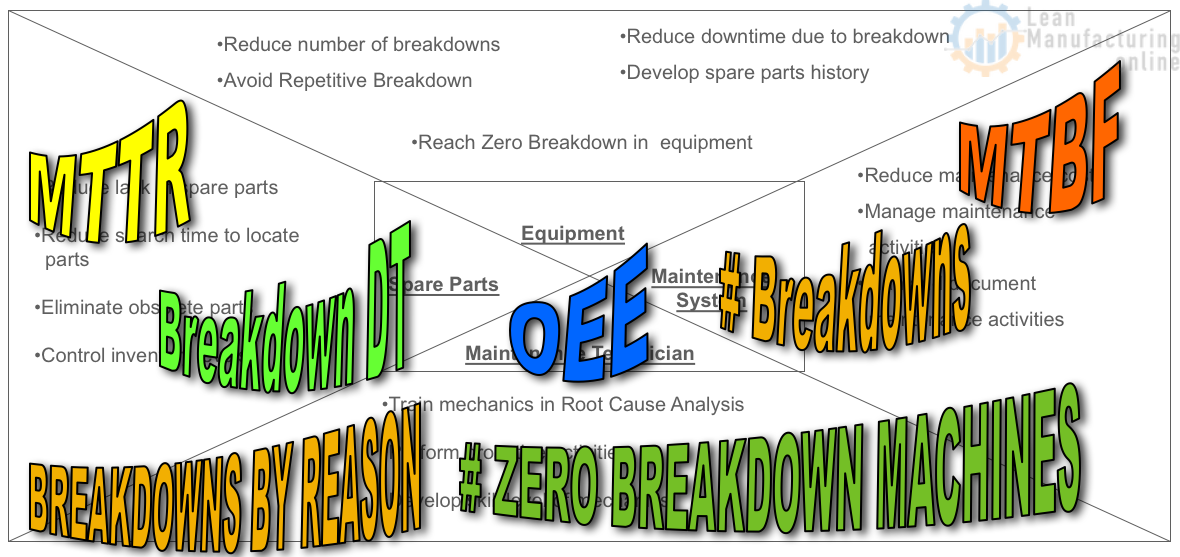

7 Step Activities of Planned Maintenance Full support of autonomous maintenance Restore Critical Equipment to Basic Condition Implement Corrective Maintenance activities Expose departments to MP activities Expand Predictive Maintenance activities Image 7 steps down below illustrates the relationship between the 4 phases for attaining zero failures and how they are subdivided into the…

Read More »The First Steps to an EFFECTIVE Planned Maintenance Pillar

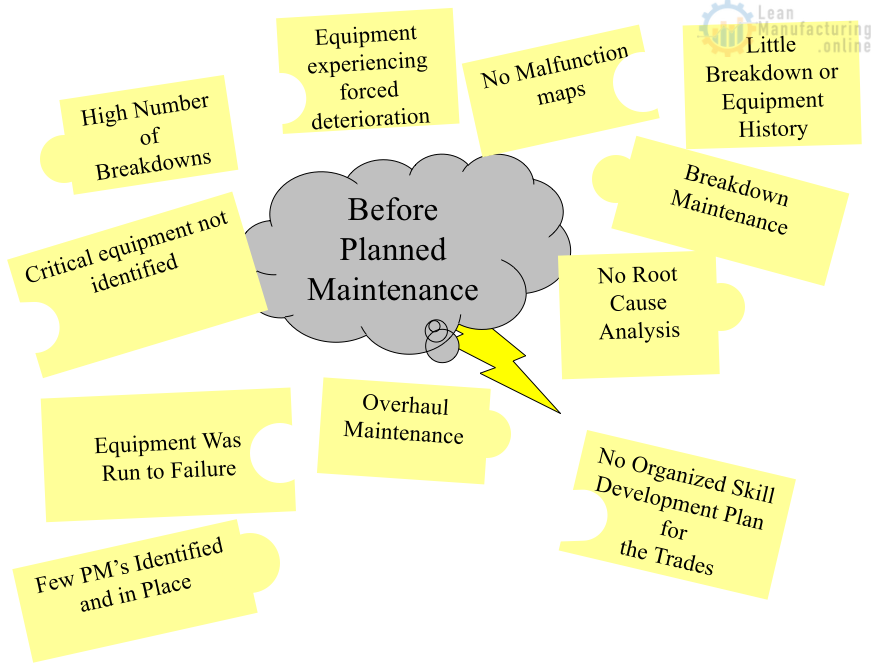

The purpose of equipment maintenance is to sustain adequate equipment condition at all times in order to have uninterrupted production. There are two main objectives of the Effective (Planned) Maintenance Pillar. What are they? ZERO BREAKDOWNS MAINTENANCE COST REDUCTION Using the 4M approach, let’s examine a typical “Before PM” situation.…

Read More »