Training

PQCDSM KPI Definitions. Part 2

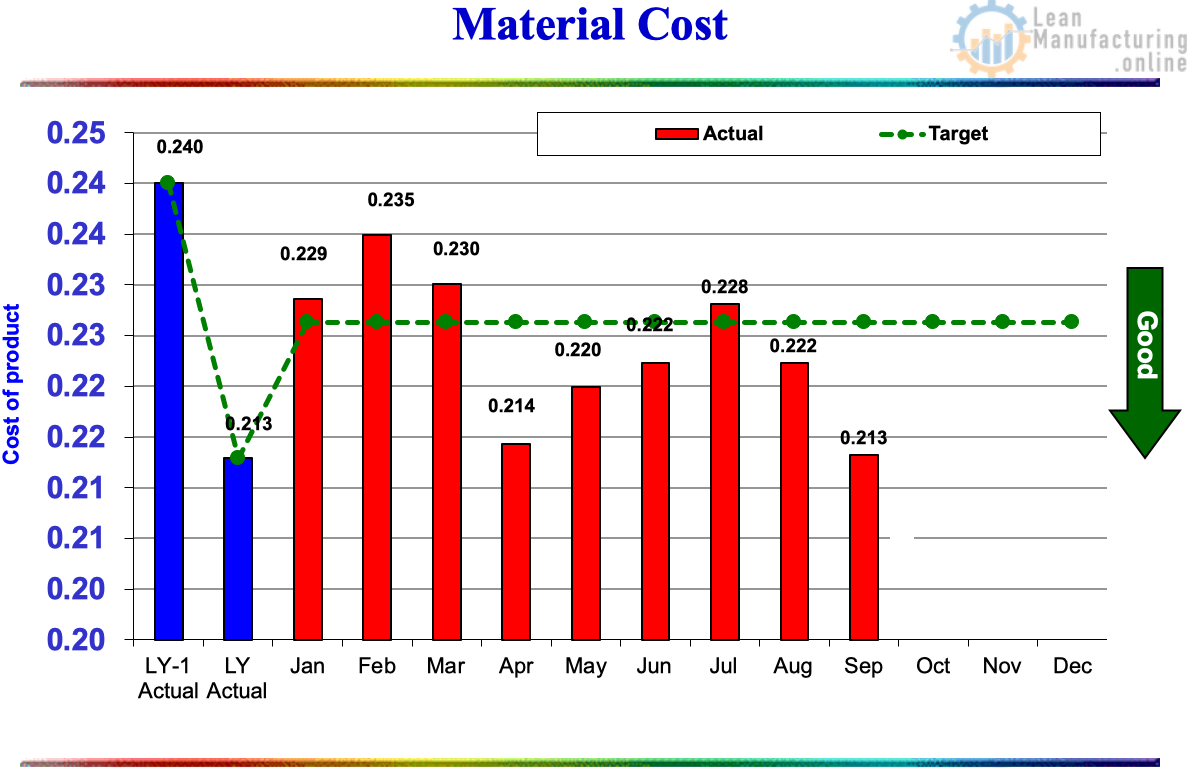

Productivity People – hours per unit volume (tonne or ‘000 units) This indicator measures labour productivity and is based on the people hours required to produce a single unit of volume. It is a measure of consumption and not cost. People-hours per unit volume = Total people-hours required within Manufacturing…

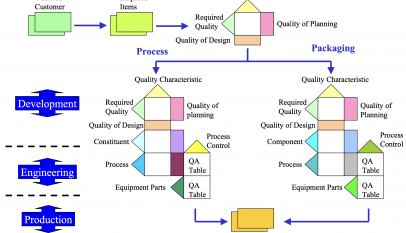

Read More »Outline of Quality Function Deployment

What is quality function deployment? In describing what quality function deployment is about, we will explain from a new perspective that is not limited to the conventional idea of “utilizing the principles of analysis and integration, diversification and visualization, generalization and localization.” Quality Function Deployment, or QFD, was developed in…

Read More »Design of Experiments

Design of experiment: used to select product characteristics and process parameters to obtain desired product and process performance.

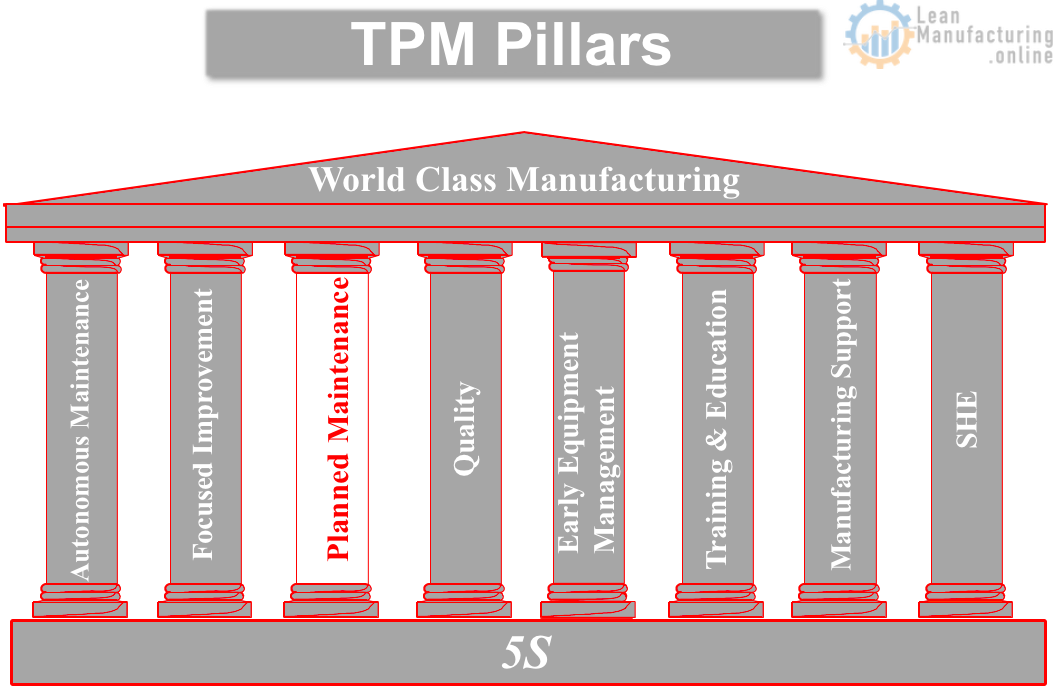

Read More »Key Recommendations for PM improvements – Case Study

The most important skill required of an operator is the ability to identify abnormalities and notice immediately when something is not quite right with the output quality or the equipment.

Read More »