World Class Manufacturing

Spare Parts Administration

PM Element 7. Indicators The Importance of Spare Parts Administration Spare parts administration is crucial for organizations that rely on equipment to operate. If a breakdown or failure occurs, having spare parts on hand can reduce downtime, minimize production losses, and improve customer satisfaction. Additionally, a well-managed spare parts program can…

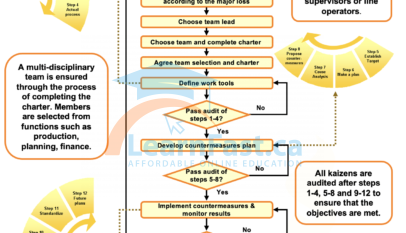

Read More »Kaizen Process

Kaizen is the critical tool for executing Continuous Improvement.

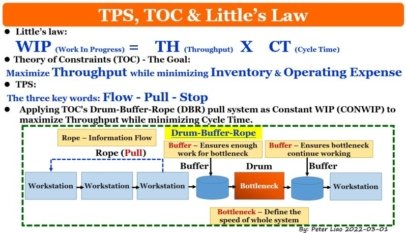

Read More »TPS, TOC & Little’s Law

"JIT" is "flow" under "pull" according to customer needs, and "autonomous" is "stop and exception management" under standardization.

Read More »Example of Food Manufacturing site review

5S Autonomous Maintenance Early Equipment Management Education and Training Manufacturing Support Planned Maintenance Quality Safety, Health and Environment World Class Manufacturing

Master Plan Show the results for the main objectives with consistent benchmarks and targets – Breakdowns, Minor Stops, Quality Defects and ZERO loss time accidents.Highlight why the Site needs TPM. “TPM is not the objective; it is the way to deliver the objectives.”Each pillar must have key indicators to link…

Read More »