When I am thinking of the five principles of lean thinking: Value, Value Stream, Flow, Pull and Perfection, I am so impressed and inspired by my LinkedIn connection with his TPS coaching experience, which can be summarized in three keywords and one sentence as follows:

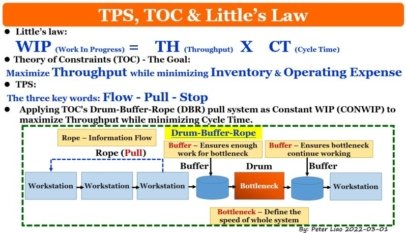

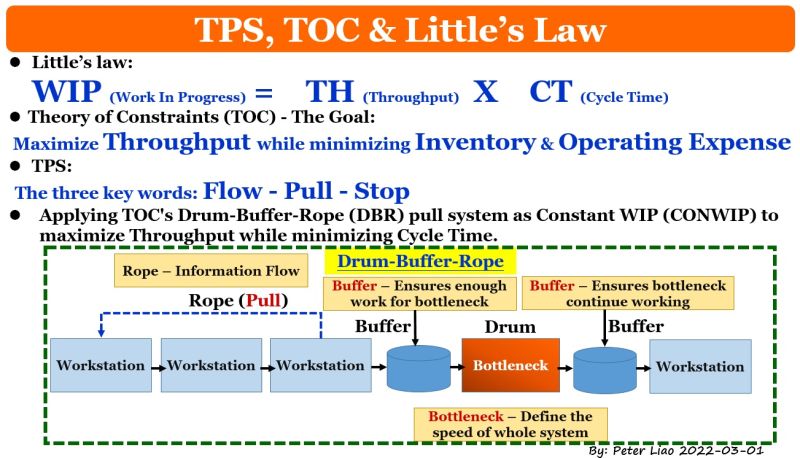

The three keywords are “Flow – Pull – Stop.”

“JIT” is “flow” under “pull” according to customer needs, and “autonomous” is “stop and exception management” under standardization. The essence of an enterprise is to deliver the products that customers want to customers as soon as possible.

These words remind me that Flow & Pull are associated with Little’s law and TOC.

Little’s law is a simple equation explaining how Waiting Time, Throughput, and Inventory are related.

WIP (Work In Progress) = TH (Throughput) X CT (Cycle Time)

It means that the lead time will also be equal to WIP/Throughput, so if a process lead time is too long, the chances are that WIP is too high. Therefore, the process Throughput must be increased or the WIP reduced to reduce the lead time.

The Theory of Constraints (TOC) focuses on identifying the bottleneck, then exploiting and elevating it, and the goal is to maximize Throughput while minimizing Inventory and Operating Expense.

LinkedIn post by Peter Liao