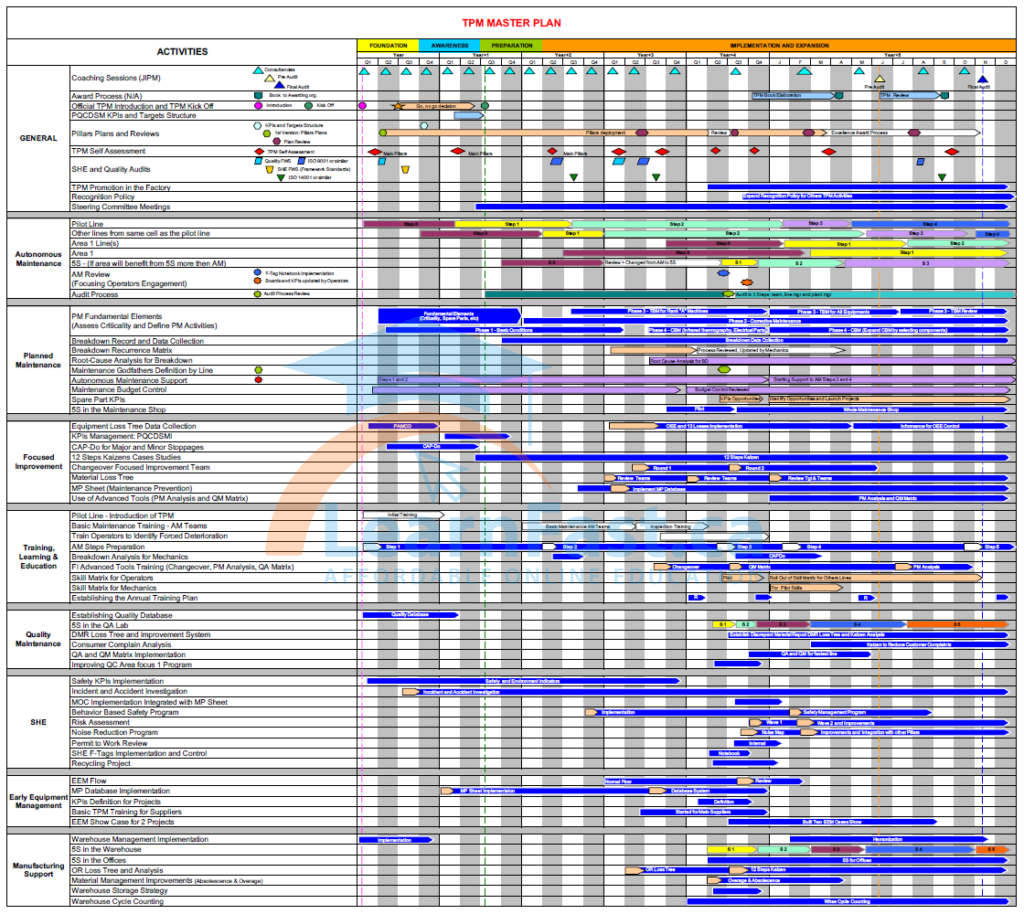

Thinking of implementing Total Productive Maintenance in your manufacturing facility? Please review a sample of the TPM Master Plan. It will help you to see and create a roadmap for TPM implementation.

To be a reference among the World-Class factories. Integrated by a winning team, recognized by the best practices in safety, community care, and environment, fully committed towards the customers’ satisfaction.

Example of the vision

We are a winning team that throughout the TPM philosophy leverage the talent of people, assuring the process and assets optimization.

Example of the mission

Our aim is to lead continuous improvement, thus achieving first-in-class performance, concerning efficiency, flexibility, cost, quality, reliability, safety, and environment.

A PDF copy of the TPM Master Plan can be downloaded here

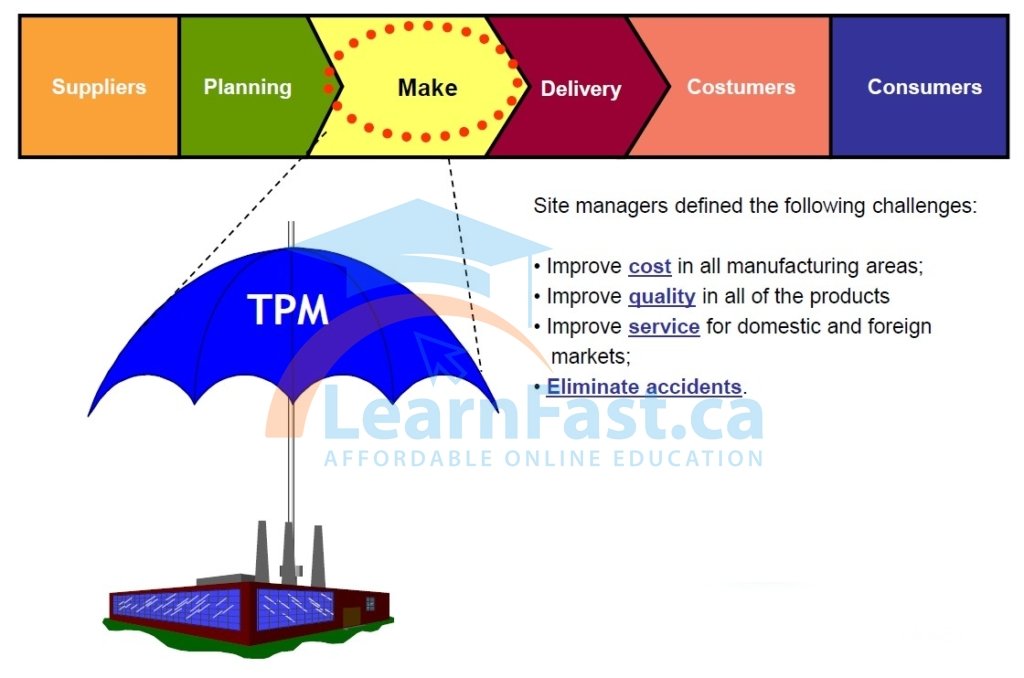

TPM Scope and Challenges

TPM implementation initiated with a focus on the manufacturing process:

Current Business Scenarios

External Factors

- Globalized markets that demand

- Higher competitivity

- Speed in innovation

- A larger variety of products

- Consumers demanding

- Higher quality

- Low cost

- Better service

- Social requirements

- Environment-friendly plant.

Factory Scenario

Next step→What is Autonomous Maintenance?