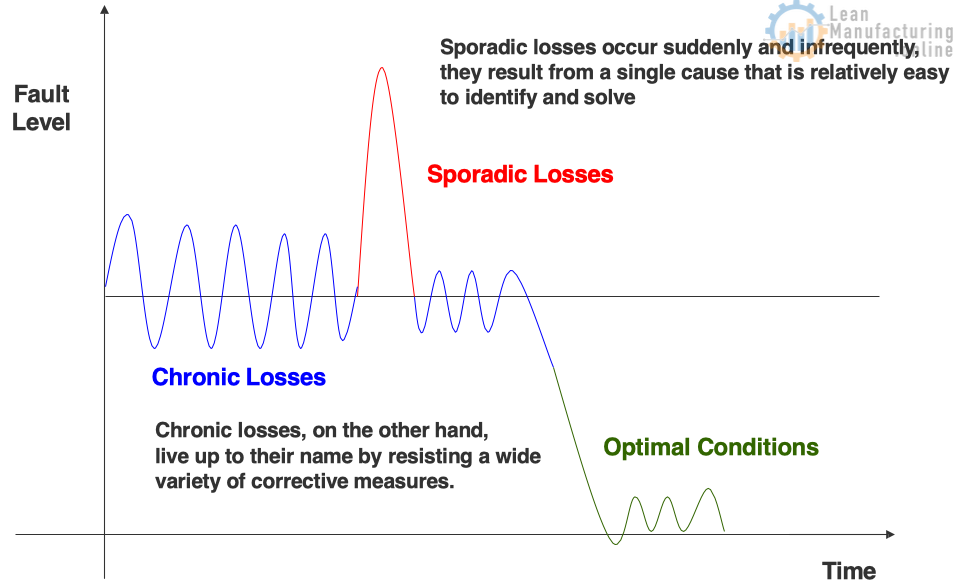

Chronic & Sporadic Losses

- Sporadic losses occur suddenly and infrequently, they result from a single cause that is relatively easy to identify and solve;

- Chronic losses, on the other hand, live up to their name by resisting a wide variety of corrective measures.

P-M Analysis

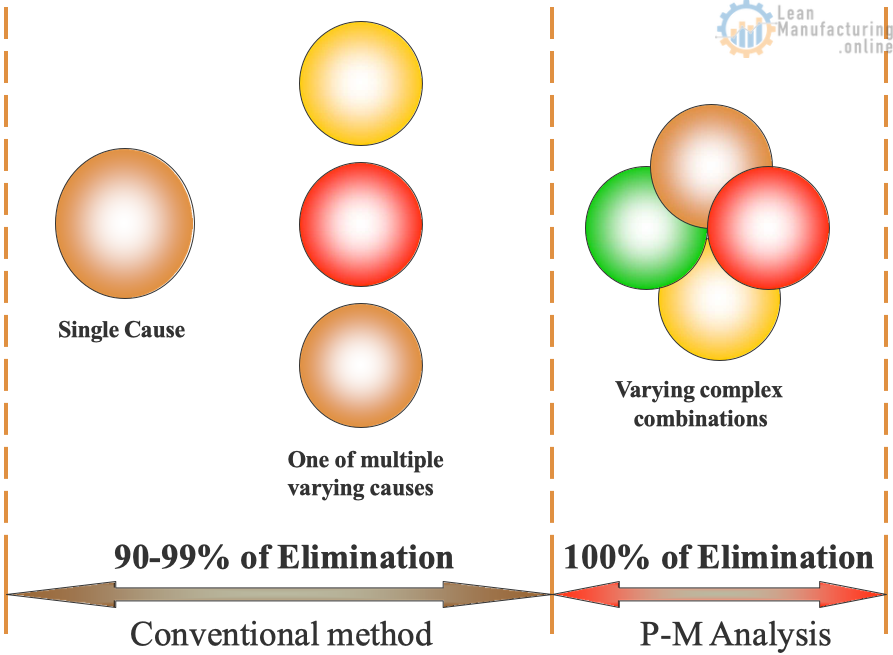

Single causes that vary constantly

Suppose for a given problem there are ten potential causes and each time the problem occurs the cause is different. Some time it may be A, some time C or D and so on. Consequently, measures focused on only specific cause cannot control the problem.

Varying combination of causes

In some case a combination of multiple and overlapping causes generates the problems. To make matters worse, each time the problem occurs, a different combination of factors may be involve. Today it may be factors A, B and C; tomorrow A, C, G and H.

Problem in reducing chronic losses

To archive a lasting reduction in chronic losses we must do three things;

- Identify all factors that conceivably contribute to a loss

- Thoroughly investigate each factor

- Eliminate any malfunctions or suboptimal conditions discovered in the process

Concept

P-M analysis is more than an improvement methodology, it is a different way of thinking about problem and context in which they occur.

- Look at phenomenon analytically and systematically

- Review all causal factors

- Identify all abnormalities and reduce them to ZERO

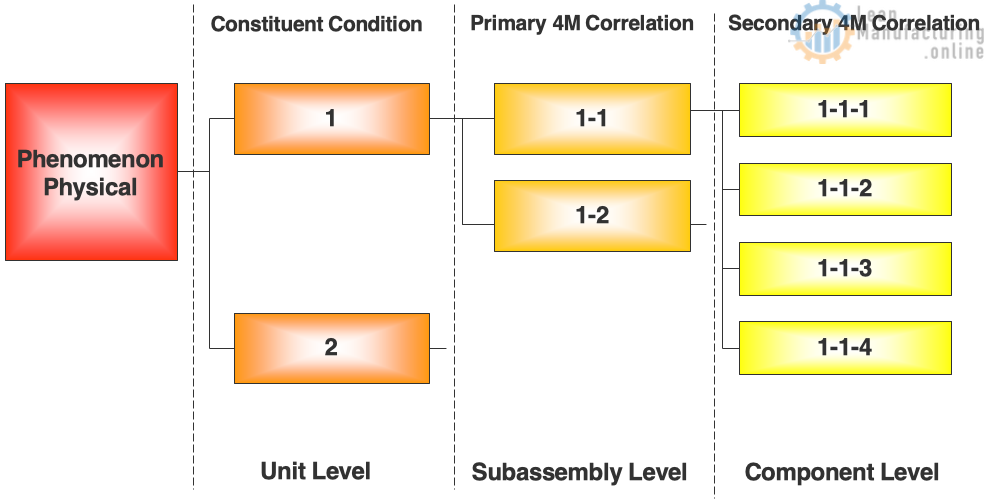

Levels of causal factor

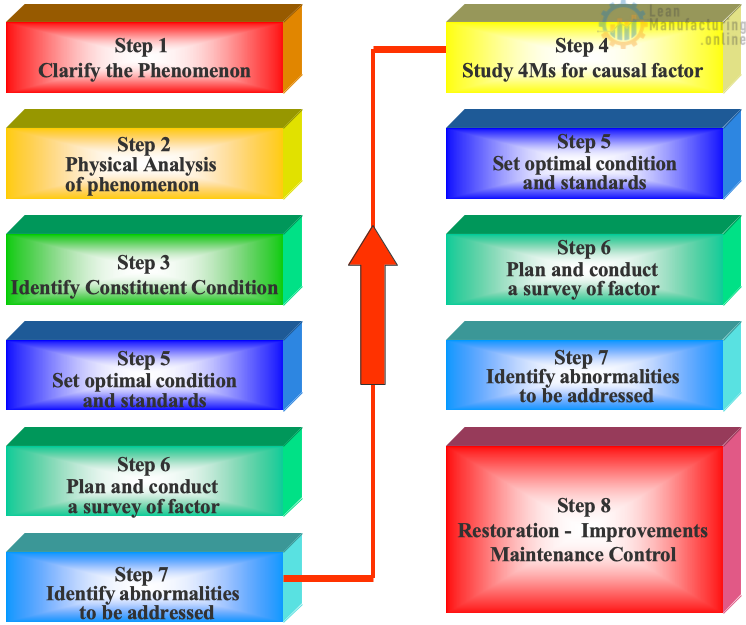

P-M Analysis steps

Step 1. Clarify the Phenomenon

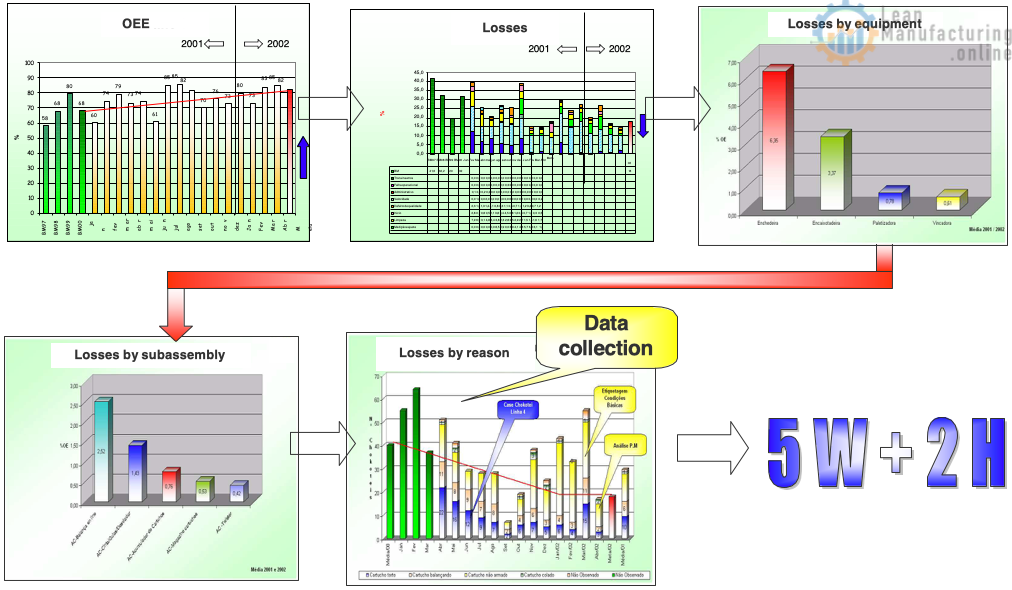

Breakdown information

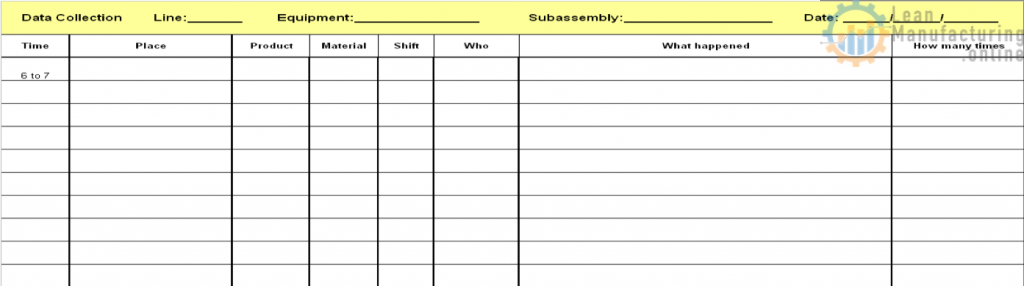

Data Collection

Phenomenon is insufficiently stratified and analyzed

It is all too easy to find manufacturing facilities where defects and failures are not carefully observed and sufficiently stratified, or broken down into discrete and differing aspects. In failing to observe the relevant phenomena carefully, people often do not notice the defect Patterns (HOW), elements (WHERE), and periods (WHEN and HOW OFTEN) that characterize them. For example, there are several ways:

- During morning startup

- Before and after blade replacement

- Before and after changeover

- During normal operation

Clarify the Phenomenon

5W + 2H

- What: What is it happening? (what the operation is seeing)

- Where: Where is it happening? (equipment or component)

- When: Any variation related to time or period?

- Who: Any variation among the people involved in the operation?

- Which: Is there any characteristic trend over time ?

How: How the situation goes from normal to abnormal condition

How Much: Total of Loss (money, product, complains, so on)

Write the phenomenon according to following:

How – What – Where – When – Which – Who and How Much

Step 2 . Physical Analysis of phenomenon

Think visually

Some people may feel ill – equipped to express themselves in technical terms, but physical analysis does not require fancy words or complicated expressions. In fact, such words would only obscure the phenomenon. The best and simplest approach is to think visually. Consider drawing of how product and equipment elements interact to bring about the defect or functional failure.

Key Steps in Physical Analysis

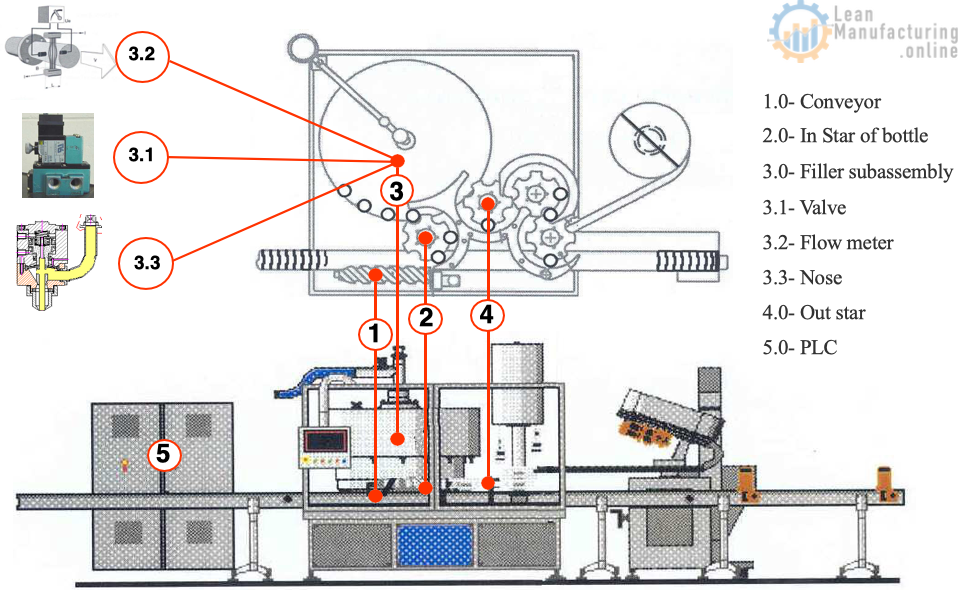

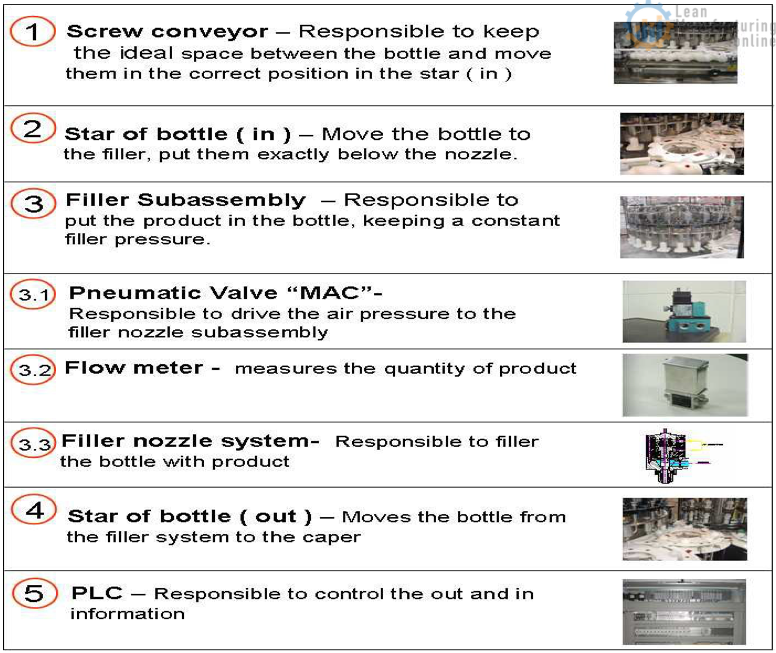

- Identify operating principles: Review machine diagrams and manuals to understand the equipment basic operating principles.

- Identify operating standards: Learn the functions and mechanisms of equipment and Devices by sketching simple machine diagrams.

- Identify interacting elements: Draw contact diagrams to identify what relationships define the phenomenon.

- Quantify the physical change involved: Identify appropriate physical quantities and change in those quantities.

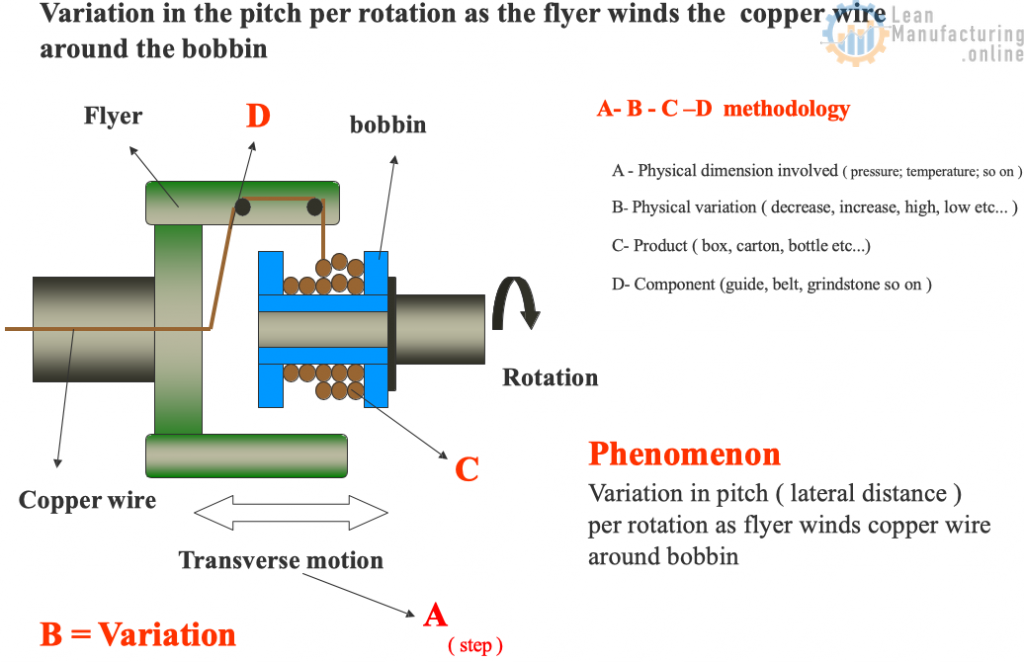

- ABCD Methodology: help us to write the phenomenon

The importance of understanding the mechanisms and its functions

Understanding the mechanisms and structure of the equipment involved is important as defining the phenomenon. Intimate Knowledge of equipment helps clarify what happens to produce particular malfunctions or defects. Mechanisms means a group of equipment elements with a single function and how it functions. Structure refers to how all the equipment elements are put together or assembled

Key Steps for understand them

- Draw the process flow

- Draw the equipment mechanisms

- Use materials to facility the comprehension , such as; technical manuals, pictures drawings so on…

- Make OPL to multiply the knowledge

Study, understand the working of system and mechanism

Analyze the phenomenon in physical term, it means, use physical principle to define the relationship the contact point between equipment and product.

A- B – C- D methodology

- A – Physical measurements involved (pressure, vacuum, temperature, distance, etc)

- B – Variation of dimension physical (increase, decrease, high, low, etc)

- C – Product (box, carton, bottle, etc)

- D – Component (guide, belt, etc)

Sequence of phenomenon description: B – A – C – D

Example

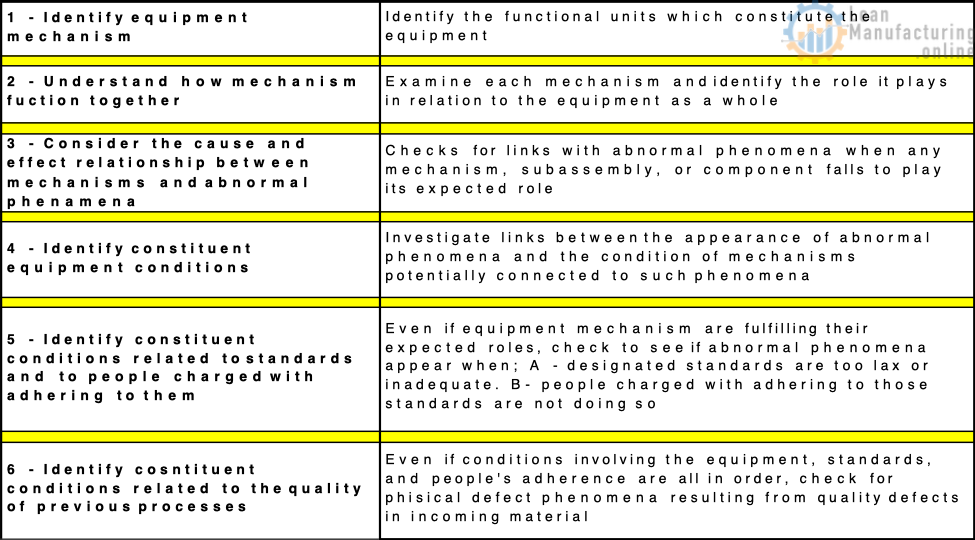

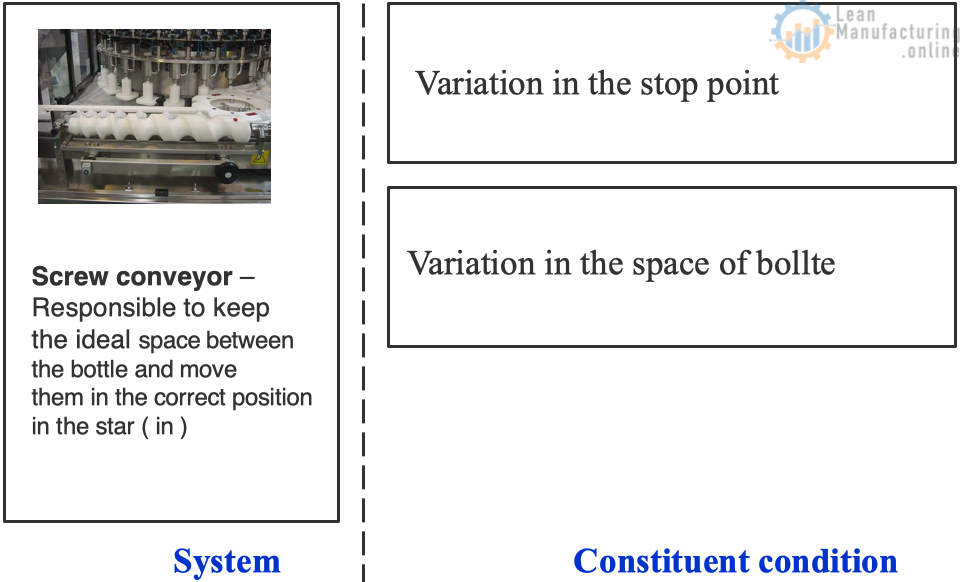

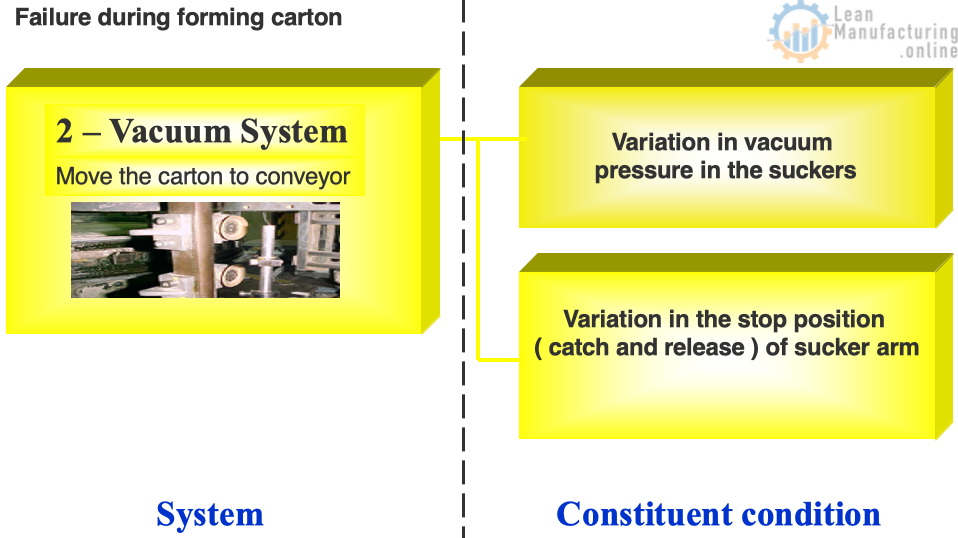

Step 3. Constituent Conditions

Procedure for checking Constituent Conditions

The steps shown in table below are helpful when checking each of the 4Ms to see whether off-standard conditions may be linked to defect phenomenon. The table provides a simple example of approach.

Identify and understand the system and mechanisms

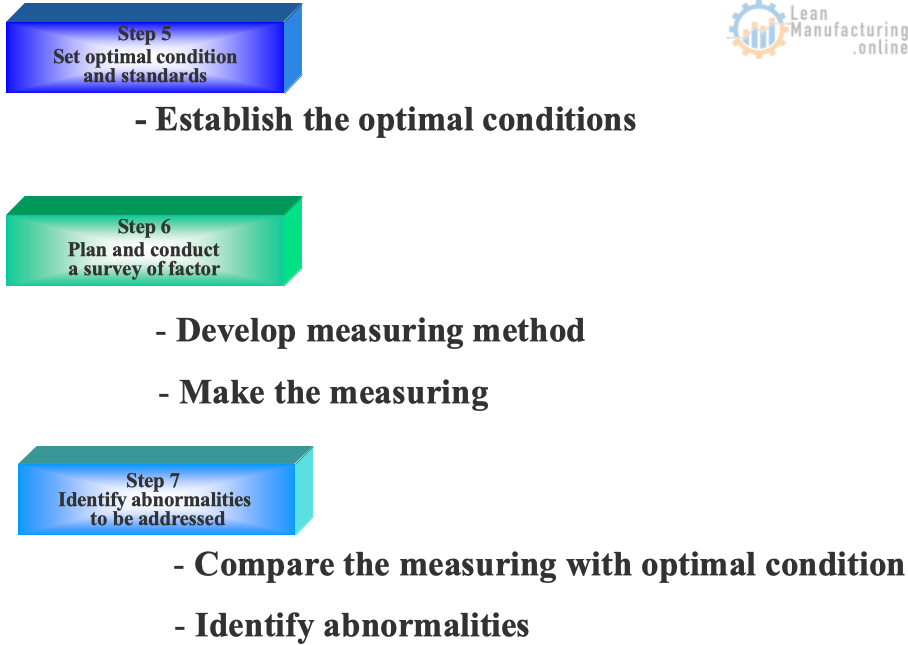

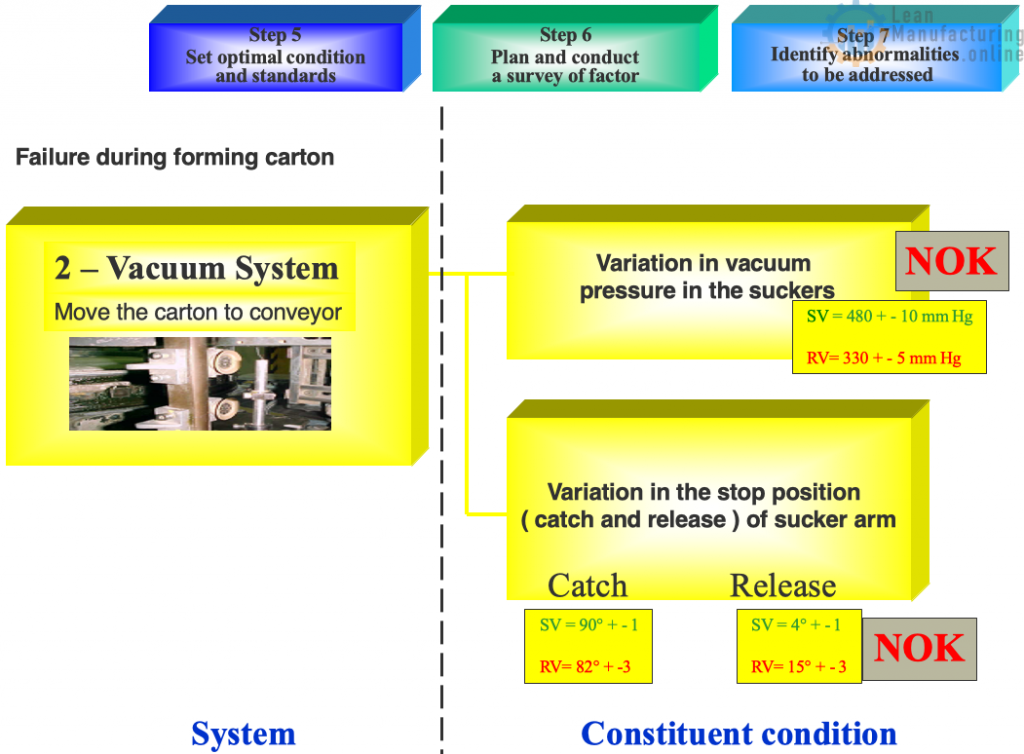

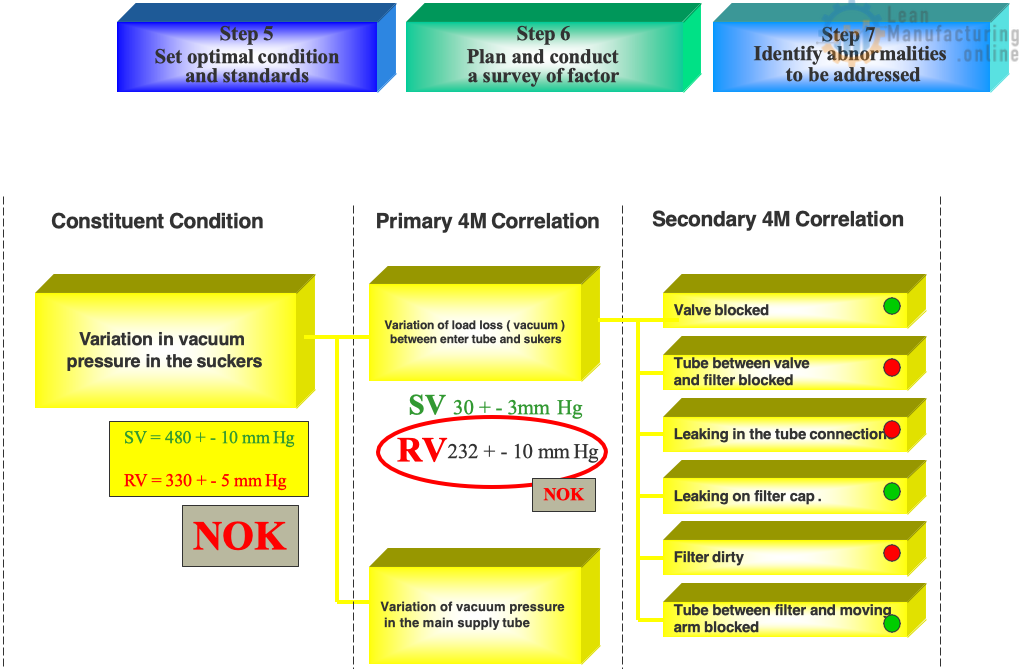

Step 5, 6 and 7.

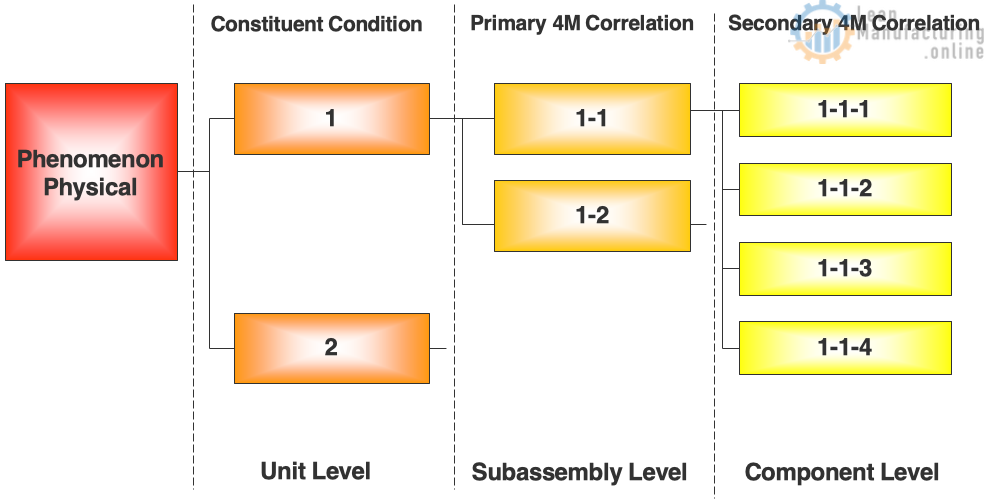

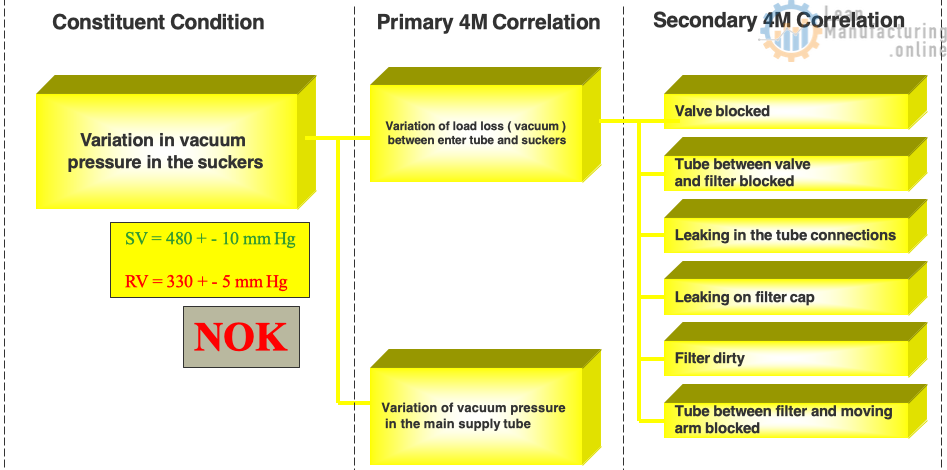

Study 4Ms for causal factors

List and investigate any correlation between the constituent condition identified in the previous step and the basic production inputs or 4Ms ( equipment, people, materials, methods ). Put another way, this means identifying cause-and-effect relationships between constituent condition specific and 4M elements. The constituent condition becomes the effect and we review 4Ms elements for potential causes. Identify all logically conceivable elements necessary to generate the constituent conditions.

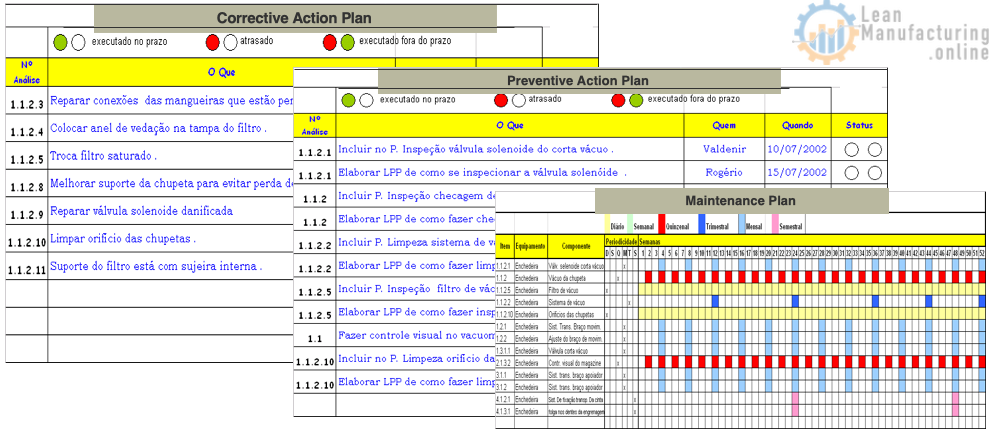

Step 8. Restoration – Improvements and Maintenance Control

Propose and Make Improvements

In this eighth and final P-M Analysis step, teams propose make any correlations and improvements required for each abnormality, then plan and institute appropriate preventive measures.

- Review the operational Procedures

- Review the cleaning procedures

- Review the inspection procedures

- Training for changes

- Record the improvement

- Review the Skill Matrix

- Make OPL

Very good explanation.

May I get copy of trg material ?

mail Id : amit.sanghvi@cii.in