Six Sigma is a data-driven methodology for reducing defects and improving quality in business processes. It uses a combination of tools and techniques to identify and eliminate sources of variability and error. Here are six common Six Sigma tools and methodologies:

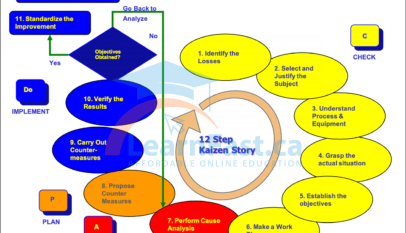

- Define, Measure, Analyze, Improve, Control (DMAIC) – This is the 5-step problem-solving framework used in Six Sigma to drive continuous improvement.

- Control Charts – These are graphical representations of process data that help identify patterns and trends, making it easier to spot potential sources of variability.

- Statistical Process Control (SPC) – This method is used to monitor and control a process using statistical methods.

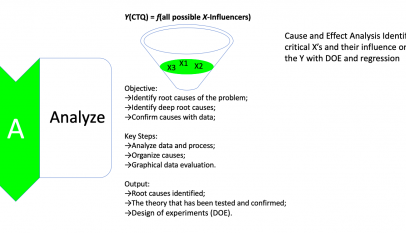

- Design of Experiments (DOE) – This is a systematic approach to testing the impact of changes on a process by manipulating variables.

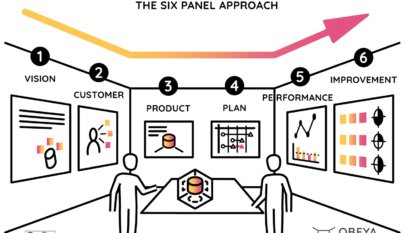

- Process Mapping – This tool is used to visually represent a process, highlighting areas for improvement and potential sources of error.

- Failure Modes and Effects Analysis (FMEA) – This is a systematic approach to identifying and assessing the potential risks associated with a process, product or service.

Example of Six Sigma Project:

A healthcare company was experiencing a high number of medical billing errors, resulting in increased costs and decreased customer satisfaction. Using the DMAIC methodology, a Six Sigma team was formed to tackle the problem.

Step 1: Define – The team defined the problem as the high number of medical billing errors and set a target to reduce errors by 50%.

Step 2: Measure – The team collected data on the frequency and type of billing errors and calculated the current error rate.

Step 3: Analyze – The team used process mapping and statistical analysis to identify the root cause of the errors. They found that the billing software was outdated and not user-friendly.

Step 4: Improve – The team recommended upgrading the billing software and providing additional training to staff on its use.

Step 5: Control – The team established a system to monitor the implementation of the improvements and track the error rate over time.

After implementing the improvements, the error rate dropped by 60%, well beyond the original target. This resulted in a significant cost reduction, improved customer satisfaction and a more efficient billing process.