Takt Time

Based on customer demand, takt time has nothing to do with how fast equipment operates or how fast workers can move. It is the blunt reality of how fast production must be to meet deadlines.

Takt time is the number of units in an order divided by the number of workable production hours.

Takt time is the rate at which a product must be produced to meet customer demand. It is calculated by dividing the total time available for production by the number of units that must be produced.

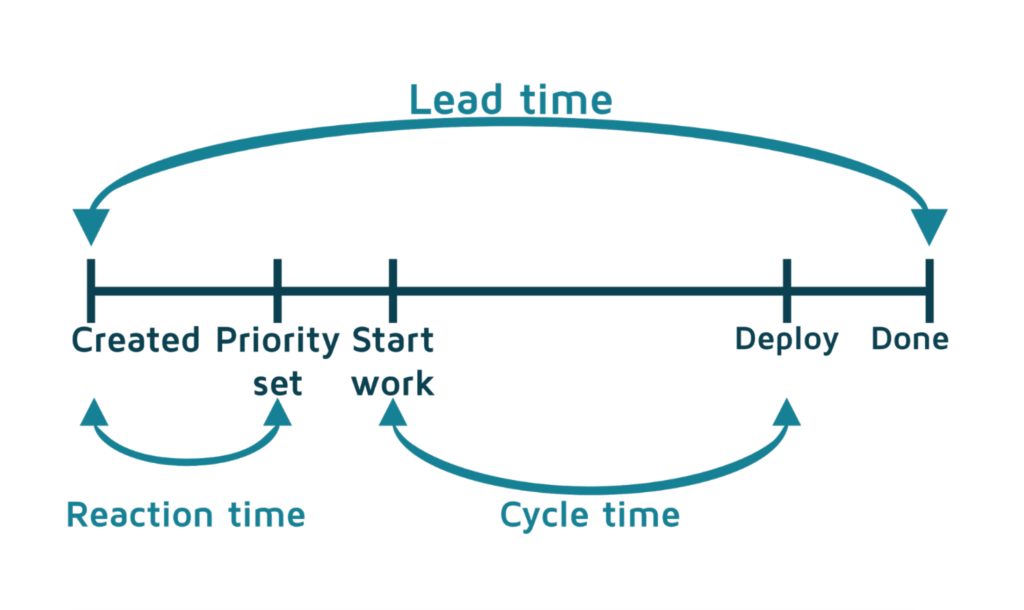

Cycle Time

Cycle time is sometimes used to describe how long it would take for equipment to complete a movement or process.

Cycle time normally refers to the time it takes to work on a unit from start to finish.

Cycle time is the time it takes to complete one process cycle. In a manufacturing setting, this could refer to the time it takes to complete one unit of a product, or it could refer to the time it takes to complete a specific step in the production process.

Lead Time

Lead time is when an order is received and delivered to the customer.

Lead time is the time it takes to complete a process or produce a product from start to finish. This can include the time it takes to receive raw materials, manufacture the product, and deliver the finished product to the customer.

These times are important in manufacturing and production settings because they can help optimize processes and ensure that products are being produced at the right rate to meet customer demand. Companies can increase efficiency and reduce waste by understanding and managing these times.

Ok excellent