Term Meaning

3D Tasks Dangerous Difficult Dirty

4M (4M’s) Categorisation of problems and solutions into Man, Method, Machine and Materials

5 Whys Problem solving technique using Why 5 times

5S (Principles) 5 basic activities to establish a foundation for TPM implementation – taken from Japanese words.

5W + 1H 5 Why’s and 1 How analysis to identify the facts only within a problem (the Phenomenon)

Activity Boards Visual display of relevant work

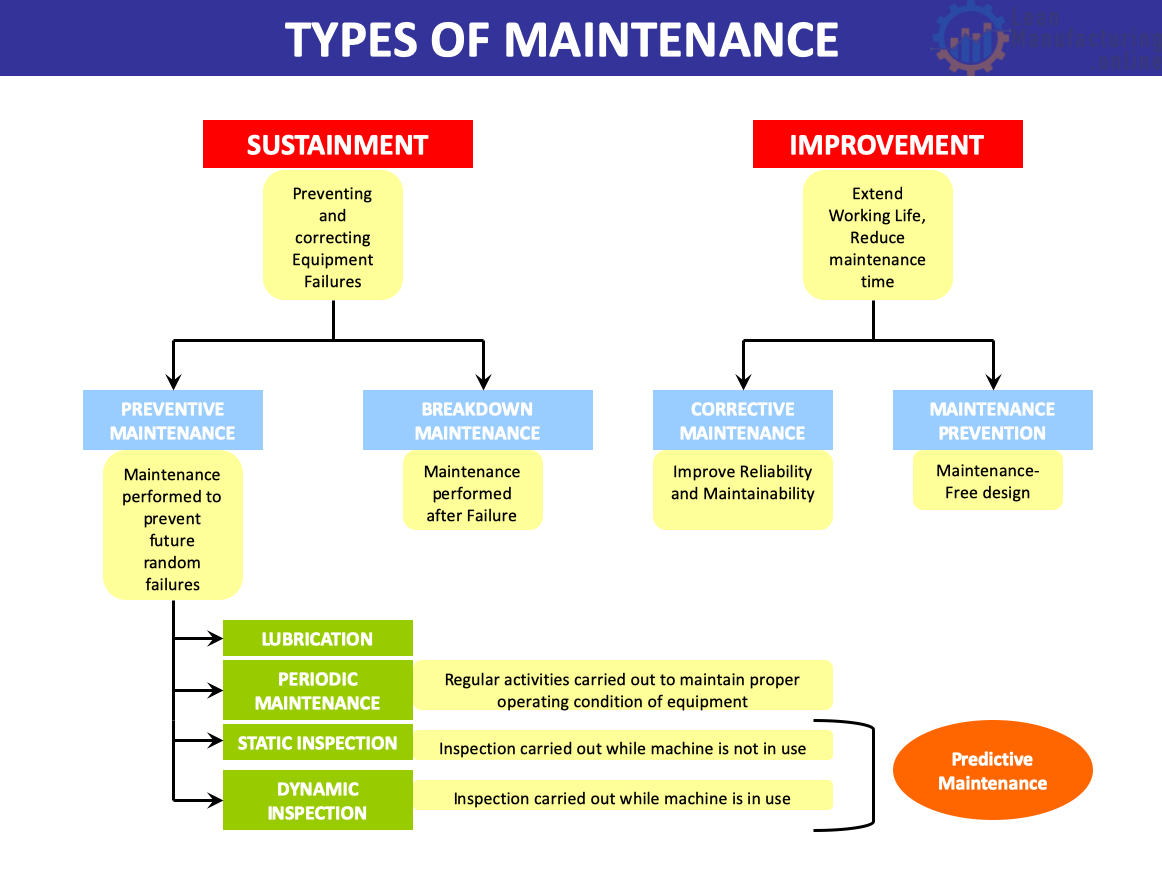

AM Autonomous Maintenance

BM Benchmark

C/O Parts Change over parts

Cascade Pass on an idea through an organization (down)

CBT Computer Based Training

CEDAC Cause and Effect Diagram with the addition of cards

CM Corrective Maintenance

CM Condition Maintenance

CONQ Cost of NON Quality

COSHH Control of Substances Hazardous to Health

DuPont Audits Safe/Unsafe Behavioural Observation/Feedback Technique used by line management/supervision

EC Environmental Care

ECRS Eliminate Combine Replace Simplify

EEM Early Equipment Management

EffM Effective Maintenance

EPM Early Product Management

E-SAP Software for purchasing and stock control

External Stakeholders People with interest in the particular activity who are not actively involved and not part of the business

FAC First Aid Cases

Feet for inspection points Visual example of showing where to stand

FI Focused Improvement activity based on loss data

FMEA Failure Mode and Effect Analysis

Gap analysis Problem solving through working out what difference lies between the current position and the goal

HACCP Approach Hazard Analysis of Critical Control Points

HAZOP Hazard and Operability Study

Horizontal Replication The application of successful/proven improvements to similar activities/equipment

Company Crisis Management SHE Standard Assessment protocol is to guide the member companies in completing their evaluation of crisis management and communications planning

IFC Initial Flow Control – technique to concurrently plan activities within EEM

Initial Clean Step 1 of Autonomous Maintenance

IPM Process Innovation Project Management

ISO International Standards Organisation

JIPM Japanese Institute of Plant Maintenance

Just-in-time Japanese Manufacturing Philosophy for collection and supply of goods

Kaizen is a Japanese word that means small steps but continuous improvement. Used to describe activity and analysis

Kaizen Leader Person running a Kaizen

Kanban Methodology for organizing stocks

KPI Key Performance Indicators

LCC Life-Cycle Costing

LiveLink Database for sharing information within the business that is web-based.

LIRD Local Improvement Record Database

Logical Analysis Problem solving using reasoned thinking

MP Maintenance Prevention

MTBF Mean Time Between Failure

MTBQF Mean Time Between Quality Failure

MTBT Mean Time Between Touch

MTTR Mean Time To Repair

SPC Statistical Process Control

NEBOSH National Examination Board in Occupational Safety and Health (UK)

No Touch Production Machinery runs without any human interaction

OEE Operational Equipment Efficiency

OH&S Occupational Health and Safety

OH&S Control Measures The technical or procedural means by which OH&S risks are reduced.

OPL One point lesson

OSHE Occupational Safety Health and Environment

OTIF On Time In Full

PCDA (R) Plan, Do Check, Act (Review)

PDCA Plan, Do, Check, Act

PDP Personal Development Plan

PHA Preliminary Hazard Assessment

Pillars evolution Continuous improvement and understanding of TPM methodologies as illustrated by the pillars.

PM Planned Maintenance

P-M Analysis Physical – mechanism relationship technique for Problem-solving

Poka-Yoke Fool-Proof or designed to be operated without training

Policy Deployment Pass on an idea down through the organization

PPE Personal Protective Equipment

PQCDSM Productivity Quality Cost Delivery Safety Morale

PQDCSMI PQCDSM + Innovation

PRIAM Project Risk Identification Assessment and Management

Process Mapping Technique used to identify systems used and when they apply

Project Charter Agreement between Customer and Group what, when and how to deliver an objective

Public Drive Area of soft copy storage available to everyone

PY Poka-Yoke

Q (components) Parts with direct influence on Quality

Q-Points Specific parts where Quality is directly influenced

QA Matrix, QM (matrix), Quality Matrix Quality Maintenance Table

QC (stories) Quality Control

QDI Quality Defect Index

QFD Quality Function Deployment

Quality Rate Used to calculate OEE taking into account quality factors

RCM Reliability-Centred Management

Returns Product sent back to SU from customer or consumer-specific

S-Points Parts that directly effect Safety

Safety Lunches An informal management/employee forum for discussing safety issues.

SAP QM Quality Maintenance within purchasing and stock control software

SC Supply Chain

Seiri Sorting Out

Seiton Setting Limits

Seiso Shining Workplace

Seiketsu Systematic Cleaning

Shitsuke Sticking to the Rules

Shadow Board Visual display which indicates by shape what is held on display

SHE Safety Health and Environment

SKU Stock Keeping Unit

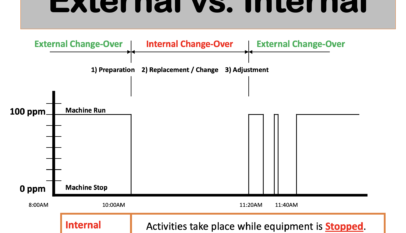

SMED Single Minutes Exchange of Dies

SOP’s Standard Operating Procedures

SPC Techniques Statistical Process Control

SU Sourcing Unit

Synchronous Production Manufacturing goods on-demand with no losses and no stocks

Tagging Activity to indicate work required on physical parts of a machine

Taguchi Method Japanese technique to establish critical part of the machine

TD Training and Development Pillar same as Education and Training Pillar

THA’s Task Hazard Analysis

Toolbox talks Presentation explaining techniques

TPM Total Productive Maintenance

TPM Cell TPM group / team / sub-committee

TPM COP Kaizen Database TPM Community of Practice Kaizen Database: WIRD

TPM Loss Tree Loss deployment methodology to measure losses in groups

TPM Pillar 1 area of activity in a factory of which there are 9

TPM SA TPM Self Assessment Audit

Underpinning knowledge Reinforcing learning through evidence

Value Engineering Technique to ensure that all factors are at the correct level

VIP Value Improvement Plan

Visual Management Use of displays and physical markings to pass on knowledge

WBLA Why Because Logical Analysis problem-solving technique

Why Why Problem solving approach similar to 5 Why, but more extensive

Zero Failure Expertise How to get to a position where zero losses can be made

Zero Losses No losses against particular areas, e.g. Zero loss line

WIRD Worldwide Improvement Record Database