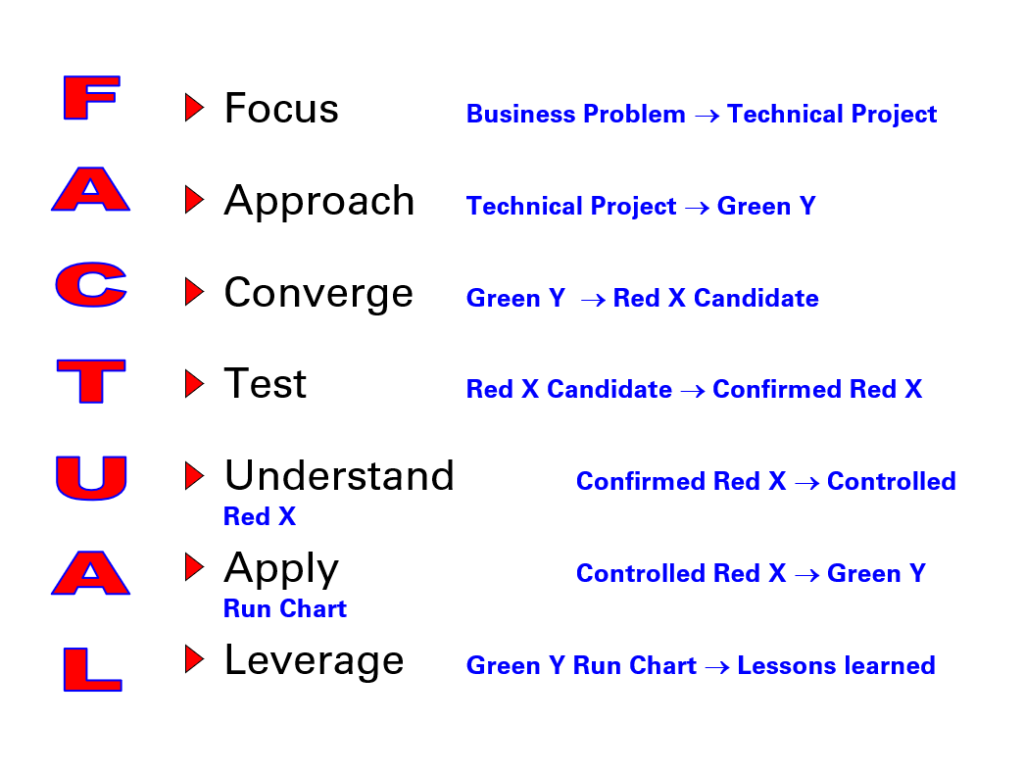

The Shainin System™ is a robust methodology that has transformed problem-solving in the manufacturing sector. Developed by Dorian Shainin, this approach, often called Statistical Engineering, focuses on identifying and eliminating the most significant source of variation within a process, known as the “Red X®.” Unlike other problem-solving methods, the Shainin System emphasizes simplicity, empirical testing, and a systematic approach to uncover the root cause of quality issues.

The Foundation: Dominant Causes of Variation

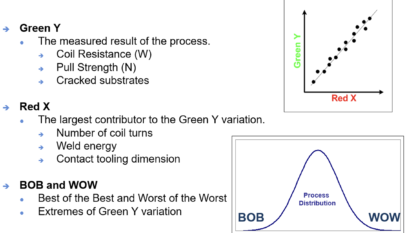

At the heart of the Shainin System is the principle that in any process, there is typically a dominant cause of variation—referred to as the “Red X.” This concept is rooted in the Pareto principle, which suggests that a small number of factors often causes a majority of defects or issues. By focusing on this dominant cause, the Shainin System allows practitioners to make significant improvements with minimal effort.

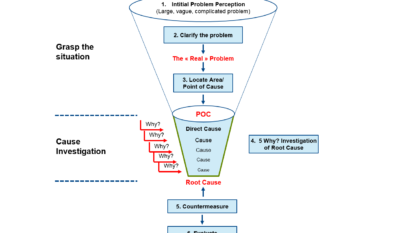

The Shainin System’s diagnostic journey begins by defining the problem and establishing a robust measurement system. This initial stage is crucial because accurate measurements are essential for identifying the Red X. Once the measurement system is in place, the process moves on to generating clues and listing suspect variables, which are systematically tested and analyzed through carefully designed experiments.

Tools and Techniques: Progressive Search and Beyond

One of the key strategies in the Shainin System is Progressive Search. This technique involves systematically narrowing down the list of potential causes by comparing groups of variables that could be contributing to the variation. By continuously eliminating variables that are not the Red X, the process gradually converges on the root cause.

Tools such as the Isoplot®, multivari chart, and Component Search™ are employed to visualize and analyze data during this process. For example, the Isoplot® helps compare the variation within a process to the measurement system’s variation, making it easier to identify whether the problem lies with the process or the measurement system itself.

The Shainin System also shuns traditional brainstorming sessions and cause-and-effect diagrams in favor of its methodical approach. This is because the system’s empirical nature relies on actual data rather than subjective ideas, ensuring that the problem-solving process is both effective and efficient.

Beyond Diagnosis: The Remedial Journey

Once the Red X has been identified, the focus shifts to the remedial journey. This involves taking irreversible corrective actions to eliminate or control the cause of variation. The Shainin System recommends setting realistic tolerances for the identified cause and applying process controls to maintain these tolerances.

Precontrol, a feedback control system unique to the Shainin System, is often used during this stage. Unlike traditional control charts, precontrol divides the specification range into zones and uses a simple set of rules to determine when process adjustments are necessary.

While the Shainin System is incredibly effective at diagnosing and addressing dominant causes of variation, it does have its limitations. For example, it may not be as effective in situations where multiple causes contribute equally to the problem. However, in most manufacturing environments, where quick and effective problem-solving is crucial, the Shainin System is a valuable tool.

The Shainin System offers a structured, data-driven approach to problem-solving that is particularly well-suited to the manufacturing industry. By focusing on the most significant source of variation, the Red X, and using empirical testing and analysis, this methodology allows organizations to make substantial quality improvements with minimal complexity.