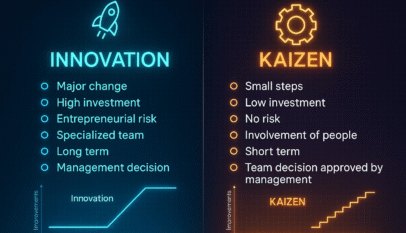

Innovation vs. Kaizen: Choosing the Right Approach to Improvement

In the world of performance improvement, two powerful approaches often dominate conversations: Innovation and Kaizen. Both offer pathways to better results—but they couldn’t be more different in how they get there.

Innovation is bold. It’s about big bets and major shifts. Kaizen, on the other hand, is humble. It values the power of incremental, steady progress.

Understanding when to use each is crucial for leaders, teams, and organizations aiming to thrive in a competitive world.

What Is Innovation? The High-Impact Route

Innovation represents disruptive, game-changing transformation. Think of it as launching a rocket—it requires fuel (investment), coordination (a specialized team), and direction (management backing).

- Major change: Often redefines the way work is done

- High investment: Capital, time, and human resources

- Entrepreneurial risk: Not all bets pay off

- Specialized team: Experts lead the charge

- Long-term focus: Results take time to realize

- Top-down decision-making: Driven by leadership

Use innovation when you’re ready to make a leap forward—not just a step ahead. Ideal for breakthrough product development, digital transformation, or reimagining your customer experience.

What Is Kaizen? The Power of Consistent Small Wins

Kaizen is built on the belief that every small improvement adds up. It’s the sum of everyday decisions made better—by the people doing the work.

- Small steps: Tiny changes repeated over time

- Low investment: Often no cost at all

- No risk: Easy to test, easy to adapt

- People-powered: Everyone contributes

- Short-term focus: Immediate feedback loops

- Team-driven: Approved with management support

Kaizen works best when looking for sustainable, team-led efficiency. It’s perfect for process optimization, 5S improvements, or daily problem-solving in operations.

How to Choose: Innovation or Kaizen?

Choosing between Innovation and Kaizen isn’t about picking a “better” method—it’s about choosing what fits the moment.

Choose Innovation when:

- You face disruptive market changes

- You’re aiming for long-term differentiation

- Your idea requires major tech or process overhaul

Choose Kaizen when:

- You want consistent progress

- Your team is closest to the process

- You’re building a culture of continuous improvement

Best Practice? Many high-performing organizations blend both. They use Kaizen to build momentum and engagement—and Innovation to make bold moves when it matters most.

Let your improvement strategy match the challenge. Whether you’re looking to scale a mountain or take daily steps, understanding the difference between Kaizen and Innovation is how you get there with confidence.