Vision

Become a value added support for Make that enables the Supply Chain to achieve superior customer service levels at the lowest possible cost.

Mission

To communicate, cooperate and coordinate Supply Chain support within Make and across the interfaces with Plan, Source and Deliver.

Objectives

- Demonstrate leadership

- TPM not just for shop floor personnel;

- Identify and eliminate Non-Value Added processes and activities in the SC interfaces with Make;

- Increase the responsiveness of Value-Added processes and activities to meet Customer’s expectations.

- Deliver business results

- Identify and eliminate waste in Make driven by ineffective interface processes (Plan, Source, Deliver) to increase Output Reliability/Schedule Adherence/Customer Service;

- Fully leverage software to manage business operations and customer relations capabilities to minimize Working Capital;

- Develop cross-functional teams capable of delivering continuous flow, value added business processes.

Key Strategies

- Leadership

- Identify, optimize and share value added business processes;

- Provide guidance on technologies that can expedite value added activities;

- 5S common office areas, QC labs and Warehouse.

- Eliminate inefficient processes

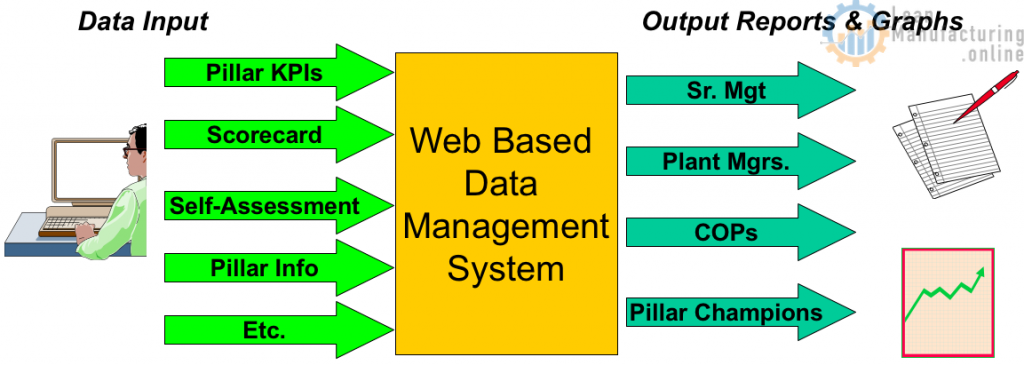

- Provide easy, quick access to all Make data reporting needs and TPM pillar information VIA portal technology

- Downtime, Loss Tree, OEE, KPI’s, Scorecard, SCIS, Benchmarking, OPL, Kaizens, Self-Assessment scores,Training Materials, Skills Matrix, Etc.

- Provide easy, quick access to all Make data reporting needs and TPM pillar information VIA portal technology

- Deliver Results

- Identify and prioritize key losses driven by Make inefficiencies or Supply Chain interfaces and apply appropriate tools/techniques to eliminate them

- Inventory accuracy, schedule changes, run strategy, forecast error, warehouse utilization, material flow, supplier quality & service, Shelf Life (Obsolescence), DOH inventory, Order/Invoice Accuracy, Schedule Attainment, Office Procedures, etc.

- Replicate successes across all plants by leveraging MSCOP organization

- Site visits (internal & external) to Benchmark for Best Practices

- Identify and prioritize key losses driven by Make inefficiencies or Supply Chain interfaces and apply appropriate tools/techniques to eliminate them

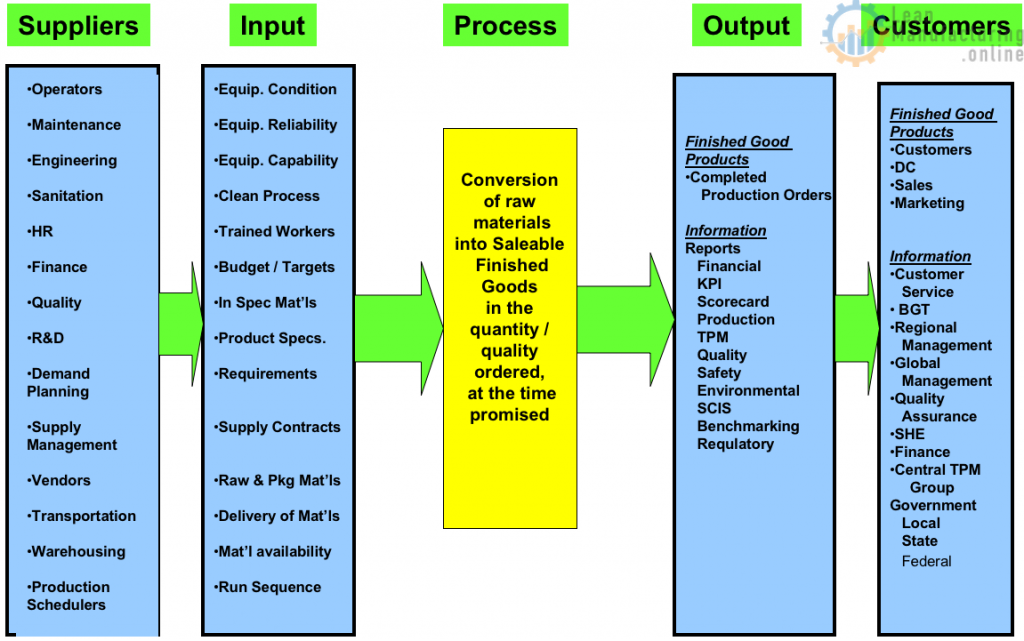

Manufacturing SIPOC

Manufacturing Support in the Manufacturing Process

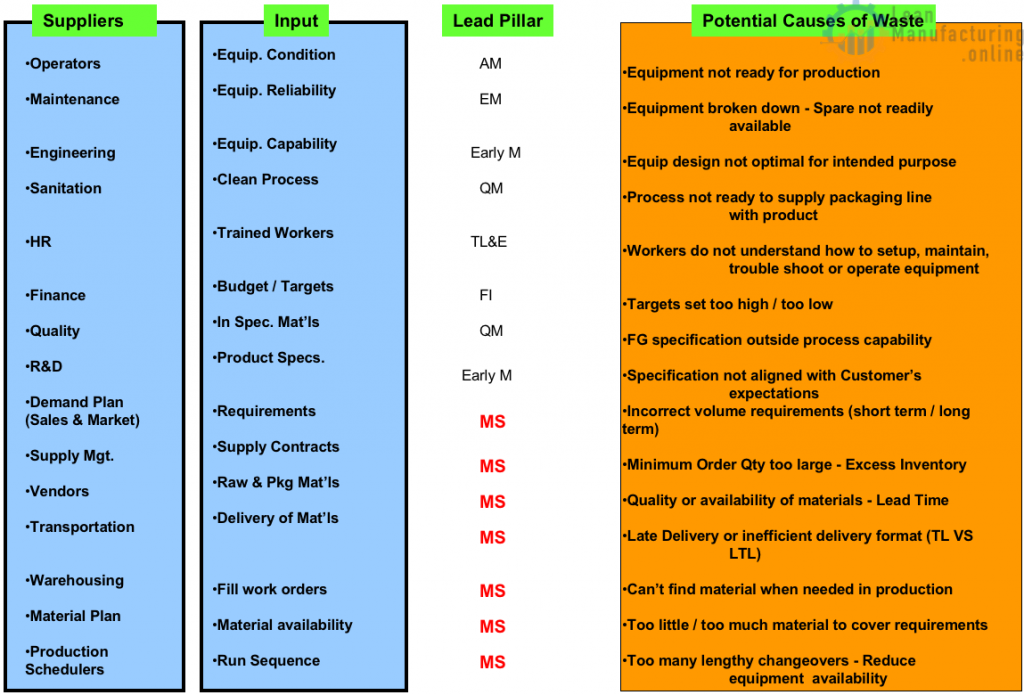

Key Interfaces

Key Interfaces

- Plan

- Demand Planning , Sales, Marketing

- Source

- Supply Planning, Vendors, Transportation

- Make

- Planner / Scheduler, Finance, Receiving, Shipping & Warehousing

- Deliver

- Logistics

- Customer Service

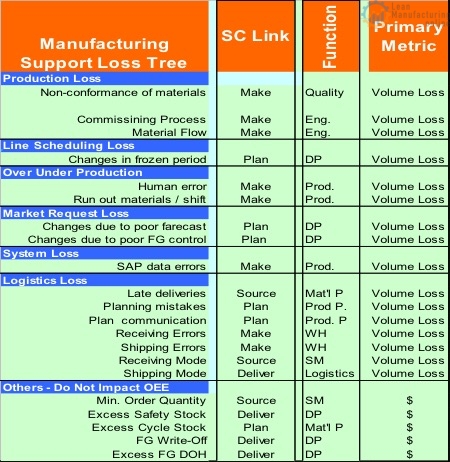

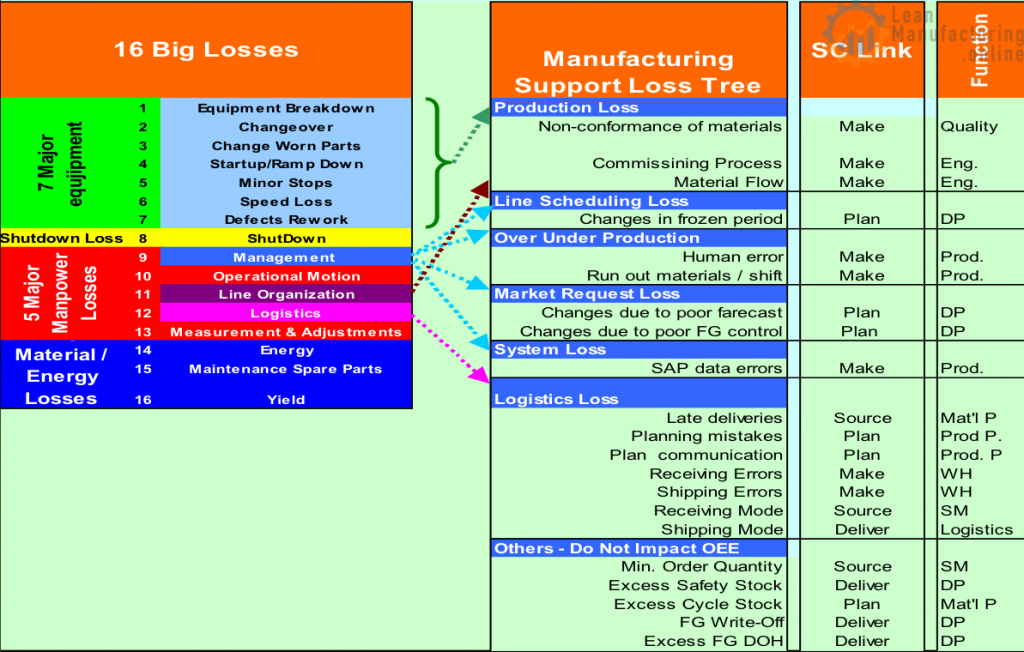

Losses overall definition:

- Production loss: Losses related to non conformance of Materials, line layout and commissioning process.

- Line Scheduling loss: Losses related to deviation on the original line plan.

- Over/under production loss: Losses related to any deviation on the production volume due to human error, deliberated decision or both.

- Logistics loss: Losses related to inbound materials availability (4M), planning mistakes or plan communication.

- Market Request loss: Losses related to requested plan changes due to poor forecast process or stock control.

- System loss: Losses related to systems such as SAP issues.

Mapping of 16 big losses to MS loss tree

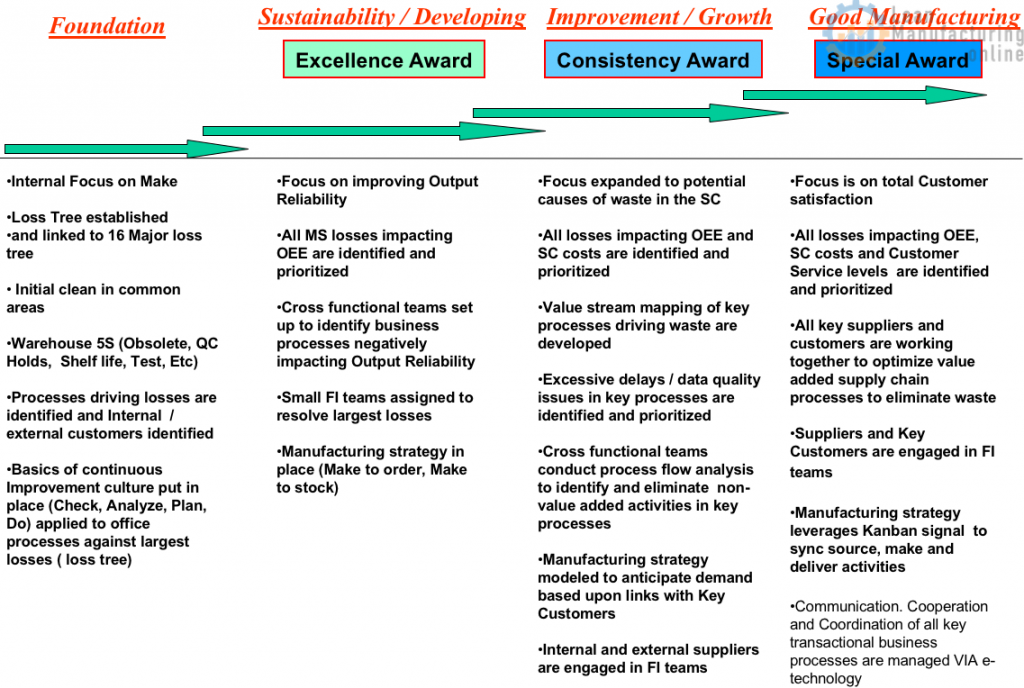

Manufacturing Support Pillar Process

Manufacturing Support KPI

KPI

- DOH – Raw, Pack & WIP Inventory

- Output Reliability (Schedule Attainment)

Other Performance Indicators

- Total Management Loss (Loss Tree)

- Number of schedule changes within frozen period

- SKU complexity

- Portfolio produced weekly (%)

- # of SC planning schedule changes

- # of Changeovers exceeding target time

- % On-Time Deliveries (Pack & RM)

- # of Errors – Receiving information

- # of Errors – Shipping information

- Raw, Pack & WIP Inventory Accuracy

- IQR (Inventory Quality Ratio – Pack, RM & WIP)

- % FG Rework

- $ FG Write-Off

Key Initiatives

- Downtime collection System

- One Place Data Entry and Retrieval

One Place Data Entry and Retrieval for all TPM related Information