Electrical Arc Flash Safety

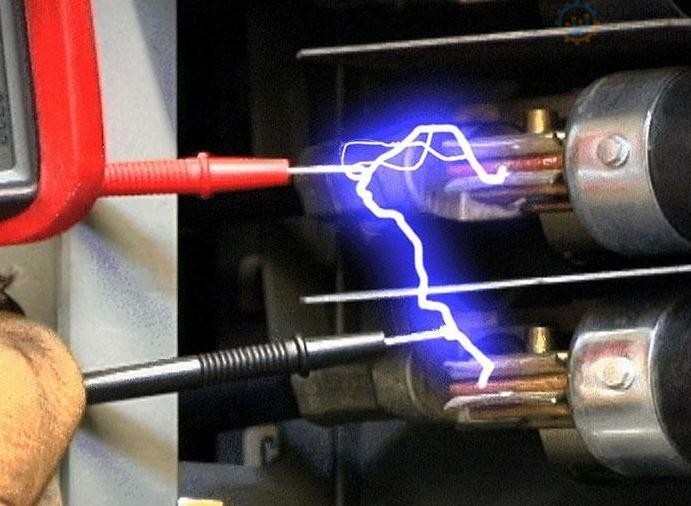

Every year many workers are treated in hospitals with major injuries related to the arch flash. The flash is instantaneous, the effects of it can last forever and be very traumatizing.

What is an Arc Flash?

“…a dangerous condition associated with the release of energy caused by an electric arc.”

What is an Electric Arc?

An electric arc is a short-circuit current passing through the air.

What are the causes of an electric arc?

Arcs can be initiated by:

- Glow-to-arc discharge

- Dust and impurities

- Corrosion

- Condensation of vapour and water

- Spark Discharge

- Accidental touching

- Dropping or leaving tools inside an open electrical cabinet

- Rodents or other animals

- Overvoltages across narrow gaps

- Failure to insulate materials

- Improper work procedures

What are the potential hazards?

Primary – Heat and Light

- Intensive UV light -> blindness

- Intensive heat -> severe burns

- Superheated ball of gas >20,000 °C

- Intense heat -> severe lung damage

- Inhalation of extremely hot air, molten metal, vaporized metal and toxic fumes

Secondary – Pressure, Auditory and Projectile

- Intensive pressure (96 kPa)

- Throws workers across the room -> bruising, broken bones, concussion, collapsed lungs and other organs trauma

- Intensive noise blast (160 dB)

- Deafness, memory loss and brain damage

- High-velocity projectiles (over 1000 km/h), molten metal and objects

- Blast shrapnel can penetrate the body

Where do they occur?

A hazardous arc flash can occur in any electrical device with high enough energy to sustain an arc.

Examples:

- Switchgear

- MCC’s

- Motor starters

- Drive cabinets

- Fused disconnects

- Busway/plugs

- Distribution panels

What are risk exposure activities?

- Racking in and out of draw-out breakers

- Removing or installing circuit breakers or fuses

- Applying Safety Grounds

- Removing panel covers for inspections or other activities

- Low voltage testing and diagnostics

What are the impacts of an arc flash incident?

Treatment can require years of skin grafting and rehabilitation. The victim may never return to work or retain the same quality of life.

The above is not quantifiable, but other direct costs are:

- Intense treatment cost

- Litigation fees, fines and imprisonment

- Company/Corporate/Personal

- Asset replacement cost

- Production loss

- Insurance fees

What are the chances of it happening?

- In North America (Canada/USA)

- 5-10 arc flash incidents occur each day that require hospitalization

- 1-2 deaths occur each day from electrical events (shock, flash and blast)

- More than 2,000 workers are treated in burn centres per year with severe arc flash injuries

What is the law, and who does it affect?

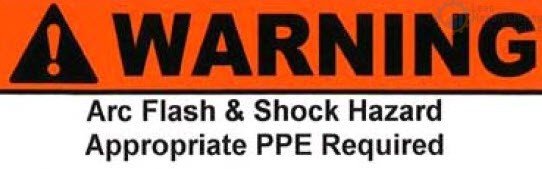

- Arc flash hazards are legislatively addressed provincially (OHSA regulation 851) and Federally (Bill C-45 added Section 217.1)

- Any workers exposed to energized equipment must be trained and equipped to be protected against arc flash hazards.

- An arc flash assessment must be conducted on applicable power distribution equipment to determine PPE

- Arc flash hazard affects all workers, supervisors, managers and owners

- CSA Z462-18 (This Standard specifies requirements for and provides guidance on safety management systems, safe

work procedures, and selection of personal protective equipment and other safety devices for persons

exposed to hazards associated with energized electrical equipment. In addition, this Standard sets out

criteria for the identification and training of qualified electrical workers and for the determination of

hazardous work to be performed only by those qualified individuals) and NFPA 70E®, 2018 Edition are harmonized and in effect - MOL expects full arc flash compliance

Review of codes & standards

Existing codes and new CSA Z462

Occupational Health & safety act

- Applicable regulations

US National Fire Protection Association

- NFPA 70E, Standard for Electrical Safety in the Workplace (2018 edition)

Canadian Standards Association

- Z462, Workplace electrical safety (2018 edition)

Institute of Electrical & Electronics Engineers

- Standard 1584

Canadian Electrical Code

- Rule 2-306

What is OHSA?

“General principles of health and safety in the workplace”

OSHA

- Section 25.(2)

- Duties of an Employer

- (a) Provide information, instruction and supervision to a worker to protect the health or safety of the worker;

- (h) Take every reasonable precaution to protect the worker.

- Duties of an Employer

Known as the “Due diligence clause.”

- Similar statements for the duties of a constructor (article 23) and duties of a supervisor (article 27)

Due diligence?

- Liability may be mitigated by showing that every precaution of “due diligence” was taken in the circumstances surrounding an incident.

- Due diligence has six essential elements notably:

- Workplace Hazard Analysis

- Company safety policy and implementation program

- Specific critical task policies and procedures

- Training procedures for workers, supervisors and managers

- Enforcement of H&S procedures

- Supervisor competence, as per CSA Z462, Section 6.6.3: “…a competent person shall

a) be a person who meets all of the requirements for a qualified person;

b) be responsible for all work activities or safety procedures related to custom or special equipment;

and

c) have detailed knowledge regarding the exposure to electrical hazards, the appropriate control

methods to reduce the risk associated with those hazards, and the implementation of those

methods.”

What is NFPA 70E?

- NFPA 70E requires safe work practices to protect personnel by reducing exposure to major electrical

hazards. Originally developed at OSHA’s request, NFPA 70E helps companies and employees avoid workplace injuries and fatalities due to shock, electrocution, arc flash, and arc blast and assists in complying with OSHA 1910 Subpart S and OSHA 1926 Subpart K.

hazards. Originally developed at OSHA’s request, NFPA 70E helps companies and employees avoid workplace injuries and fatalities due to shock, electrocution, arc flash, and arc blast and assists in complying with OSHA 1910 Subpart S and OSHA 1926 Subpart K. - Was a de facto standard adopted by Canadian companies

- Released in 2008 and revised in 2015 and 2018.

Should be used in conjunction with other codes and standards, i.e. Canadian Electrical Code C22.1/2/3

What is CSA standard Z462?

- This Standard is based on NFPA 70E, the Standard for Electrical Safety for the Workplace, and has been

harmonized with Parts I, II, and III of the Canadian Electrical Code; CSA Z460, Control of hazardous

energy — Lockout and other methods; and CSA M421, Use of electricity in mines. - Released in 2008 and revised in 2015 and 2018.

Should be used in conjunction with other codes and standards, i.e. Canadian Electrical Code C22.1/2/3

What is IEEE standard 1584?

1584 – IEEE Draft Guide for Performing Arc-Flash Hazard Calculations

This guide provides mathematical models for designers and facility operators to apply in determining the arc-flash hazard distance and the incident energy to which employees could be exposed during work on or near electrical equipment.

What is CEC rule 2-306?

- CEC rule 2-306 applies to equipment installed or modified after the

date the rule became effective (2006 in most jurisdictions). - The owner of the electrical distribution equipment is ultimately

responsible, either directly or through the installing contractor, for

ensuring that the warning labels are installed when required.

What are the elements of the CSA standard Z462?

- Electrical safety program

- Qualified personnel

- Establishment of electrically safe working conditions

- Hazard/risk evaluation procedures

- Job briefing and planning

- Energized electrical work permits

- Arc flash study and analysis

- Incident energy levels

- Limits of approach and flash protection boundaries

- PPE

- Hazard Risk Analysis

- Labels

- Training

What is Arc Flash Incident Energy?

Thermal Incident Energy is measured in Calories/cm2 (1.2 Calories/cm2 is the threshold of a second-degree burn). Arc Flash protection is to limit the injury to no more than the ‘just curable” 2nd Degree Burn. Personal Protective Equipment (PPE) is selected based on this Calculated Value.

Host/Contract Employer’s Responsibility

- Host

- Inform the contract employer of

- Known Hazards

- Information on Installation to allow for Hazard Assessment (If applicable)

- Inform the contract employer of

- Contractor

- Ensure Workers are instructed in the Hazards communicated by the Host (In addition to the Training required by the codes)

- Workers follow the best work practices and policies of the Host

The contractor should advise Host of any additional Hazards not communicated and measures taken to prevent future occurrences. Observed Violations should be reported to the respective Host/Contract Employer.

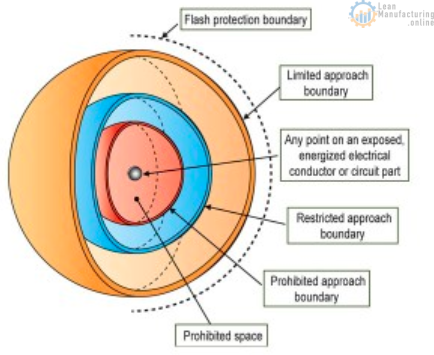

What are shock and arc flash boundaries?

Shock Protection Boundaries

Limited Approach Boundary – Distance from an exposed live part within which a shock hazard exists.

Restricted Approach Boundary – Distance from an exposed live part within which there is an increased risk of shock due to an electrical arc combined with the inadvertent movement of personnel working near the live part.

Arc Flash Boundaries

Working Distance – Dimension between the possible arc point and head and body of the worker positioned in place to perform the assigned task. The value selected for the application – is a minimum of 18″.

Flash Protection Boundary – Distance from an exposed live part within which a person could receive a second-degree burn if an electrical arc flash were to occur. This second-degree burn results from the minimum arc flash energy of 1.2 cal/cm2 ( = 5 joules/cm2). This boundary is determined by calculating the distance at which an arc flash energy of 1.2 cal/cm2 exists.

Qualified personnel

Excerpts from “4.1.7.1.2 Training of qualified persons” Z462-18:

“…Qualified persons shall be trained in and knowledgeable about the construction and operation of

equipment or a specific work method and trained to identify and avoid the electrical hazards that might

be present concerning that equipment or work method.”

Note: A person can be qualified for certain tasks and in the use of certain equipment and methods and yet be unqualified for other tasks and in the use of other equipment and methods.

“..permitted to work within the limited approach boundary shall, at a minimum, be additionally trained in the following:

i) the skills and techniques necessary to distinguish exposed energized electrical conductors and

circuit parts from other parts of electrical equipment;

ii) the skills and techniques necessary to determine the nominal voltage of exposed energized

electrical conductors and circuit parts…”

“…Trained in the decision-making process necessary to:

- Perform safety planning (job/task);

- identify electrical hazards;

- assess the associated risk;

- select the appropriate risk control methods (See 4.1.5.7 and Annex F), including PPE;

- Eliminate, Substitute, Control and/or Create Systems;

- Personnel in Training provided under the direct supervision of a Qualified Person;

- Task performed less than once a year shall require Retraining before the Work Practices involved are performed;

- Must be trained to select an appropriate Voltage Detector and shalt demonstrate how to use a device to verify the absence of voltage, including the Interpreting indications provided by the device;

- Training shall include information that enables the Worker to understand all limitations of each specific Voltage-Detecting Device that may be used…”

Excerpts from NFPA 70E:

“…1910.335(a)(1)(i) Employees working in areas where there are potential electrical hazards shall be provided with and shall use, electrical protective equipment that is appropriate for the specific parts of the body to be protected and for the work to be performed.

Note: This part contains personal protective equipment requirements in subpart I.

1910.132(d)(1) The employer shall assess the workplace to determine if hazards are present, or are likely to be present, which necessitate the use of personal protective equipment (PPE)…”

Why is FR Needed?

- Most severe burn energies and fatalities are caused by non-flame-resistant clothing igniting and continuing to burn.

- Flame-resistant clothing will self-extinguish, thus limiting the injury

- Body area under non-FR clothing is often burned more severely than exposed skin

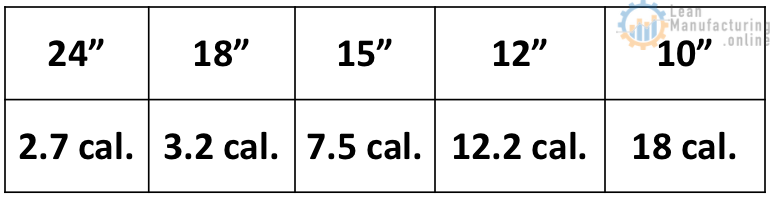

Arc Energy vs Distance

Energy goes up dramatically as distance from the arc drops:

EXAMPLE: 22,000A, 480V, 6 cycles:

How close are you to the arc?

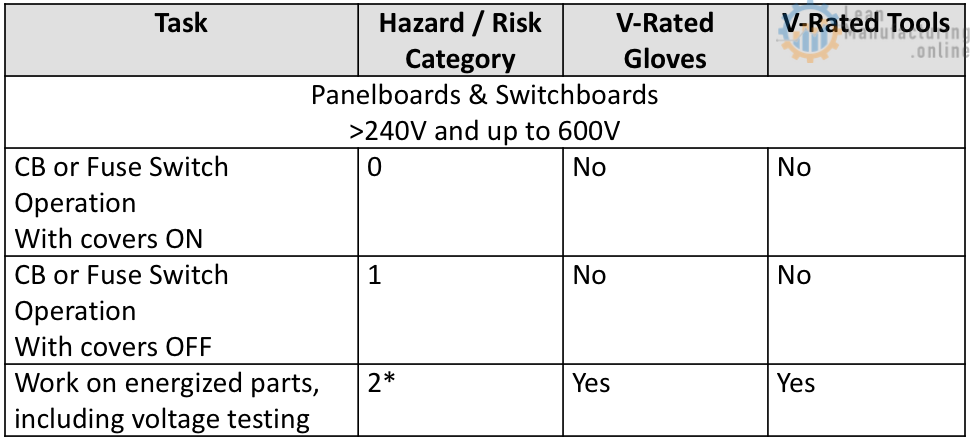

What PPE Do I Have to Wear?

NFPA uses a three-step process:

Step 1: Determine the Hazard / Risk Category Classification based on NFPA 70E Table 130.7(C)(9)(a)

NFPA Hazard Risk Categories

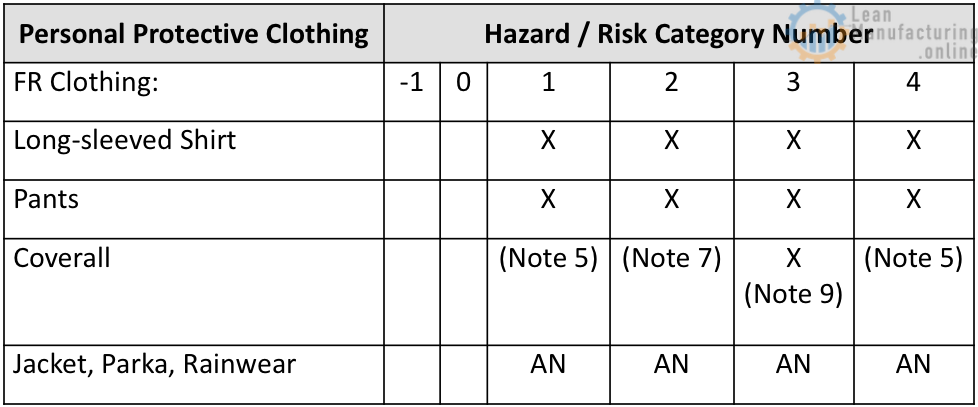

Step 2: Select Protective Clothing and PPE based on NFPA 70E Table 130.7(C)(10).

NFPA Hazard Risk Categories

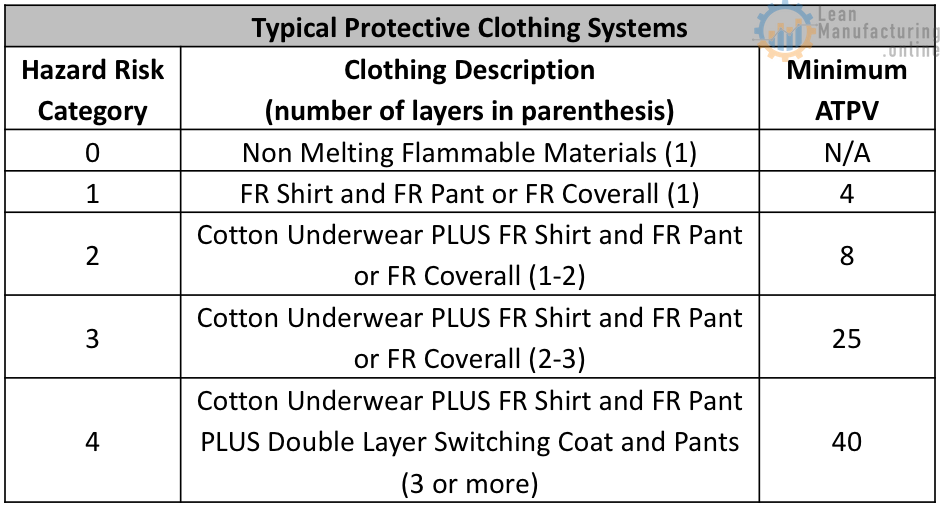

Step 3: Identify Minimum ATPV and System based on HRC From Table 130.7(C)(11)

These tables are used for demonstration purposes only. Always refer to NFPA 70E for actual requirements.

Arc Thermal Protection Value

Arc Thermal Protection Value (ATPV) is defined by ASTM F 1959-00 as:

“the incident energy on a fabric or material that results in sufficient heat transfer through the fabric or material to cause the onset of a second-degree burn based on the Stoll Curve”

The 70E Solution

Confused by the selection process?

The national trend is single-layer HRC 2 daily wear and HRC 4 flash gear

Don’t let confusion delay your PPE selection!

What is Flame Resistant Clothing?

- Clothing made from fabrics that self-extinguish

- Fabrics may be natural or synthetic

- Designed to limit (not eliminate) burn injury

- Survival, the extent of injury, recovery time and quality of life are all dependent on FRC performance.

Engineered Flame Resistant Fabrics

- Natural fibres

- Synthetic fibres

- Natural/synthetic blends

NOTE: Flame resistance must be durable to launderings, wear, the environment, etc. for the service life of the garment

Look for proven products!

Proper Use

- FRC should be appropriate to hazard

- Always the outermost layer

- Worn correctly; zipped, buttoned, etc

- All-natural, non-melting undergarments

- Clean, no flammable contaminants

- Repaired correctly and removed from service when needed

Insulating Gloves: Types

Insulating gloves come in two “types”:

Type I

Pro: Greater flexibility and “feel.”

Con: Not ozone-resistant, will crack if exposed to ozone or UV over time.

Type II

Pro: Ozone-resistant.

Con: Not as comfortable to wear (less flexible)

Ozone is a form of oxygen found in the air surrounding a conductor in high voltages. It can cause dangerous cracks in rubber products, including insulating gloves, thus rendering them unsafe. Type I rubber gloves can also be negatively affected by UV light, so care should be taken to store and inspect these gloves properly.

The Type II gloves are not as susceptible to ozone and UV rays; however, they are not as flexible as Type I and, therefore, more uncomfortable to wear.

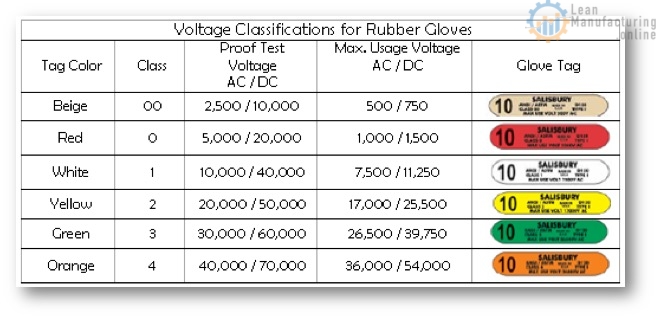

Insulating Gloves: Class

FAST FACT: Remember, it’s not the colour of the glove that’s important – it’s the colour of the tag!

Glove Markings

1910.137(a)(1)(iv) Markings on gloves shall be confined to the cuff portion of the glove.

Class & Type designations are found on the cuff portion of the glove.

Protector Gloves

1910.137(b)(2)(vii) Protector gloves shall be worn over insulating gloves, except as follows:

1910.137(b)(2)(vii)(A) Protector gloves need not be used with Class 0 gloves under limited-use conditions, where small equipment and parts manipulation necessitate unusually high finger dexterity.

Note: Extra care is needed in the visual examination of the glove and in the avoidance of handling sharp objects.

Protector gloves must be worn over insulating gloves, except for Class 0 gloves, under limited-use conditions, where small equipment and parts manipulation necessitate unusually high finger dexterity.

FAST FACT: Do not use leather protectors alone for protection against electric shock. Serious injury or death could result. Always use proper rubber insulating gloves.

Glove

1910.335(a)(1)(ii) Protective equipment shall be maintained in a safe, reliable condition and shall be periodically inspected or tested, as required by 1910.137.

1910.335(a)(1)(iii) If the insulating capability of protective equipment may be subject to damage during use, the insulating material shall be protected. (For example, an outer covering of leather is sometimes used to protect rubber insulating material.)

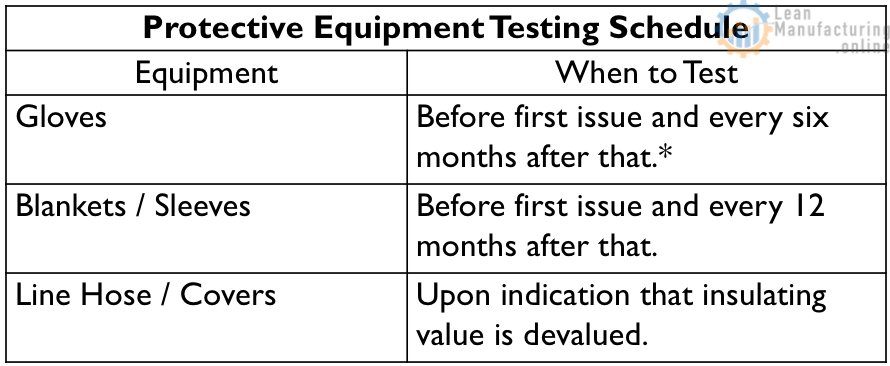

Glove Testing

1910.335(a)(1)(ii) Protective equipment shall be maintained in a safe, reliable condition and shall be periodically inspected or tested, as required by 1910.137.

1910.335(a)(1)(iii) If the insulating capability of protective equipment may be subject to damage during use, the insulating material shall be protected. (For example, an outer covering of leather is sometimes used to protect rubber-insulating material.)

* If the protective equipment has been electrically tested but not issued for use, it may not be placed in service unless it has been electrically tested within the previous 12 months.

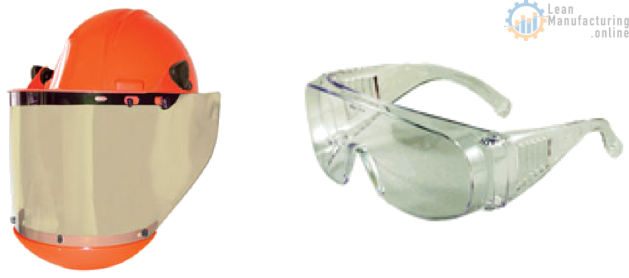

Eye Protection

1910.335(a)(1)(v) Employees shall wear protective equipment for the eyes or face wherever there is a danger of injury to the eyes or face from electric arcs or flashes or flying objects resulting from electrical explosions.

Eye protection is required whenever there is a danger of injury to the eyes or faces from electric arcs or flashes, or flying objects resulting from an electrical explosion.

Head Protection

1910.135(b)(1)

Protective helmets purchased after July 5, 1994, shall comply with ANSI Z89.1-1986, “American National Standard for Personnel Protection-Protective Headwear for Industrial Workers-Requirements,“ which is incorporated by reference as specified in Sec. 1910.6 or shall be demonstrated to be equally effective.

1910.335(a)(1)(iv) Employees shall wear nonconductive head protection wherever there is a danger of head injury from electric shock or burns due to contact with exposed energized parts.

1910.135(a)(2) The employer shall ensure that a protective helmet designed to reduce electrical shock hazard is worn by each such affected employee when near exposed electrical conductors which could contact the head.

ANSI Markings

The following information must be marked inside the helmet

- Manufacturer’s name

- The “ANSI Z89.1-1997″ designation

- Class designation (G, E or C)

- Date of manufacture

Protective Footwear

1910.136(a) General requirements. The employer shall ensure that each affected employee uses protective footwear when working in areas where there is a danger of foot injuries due to falling or rolling objects or objects piercing the sole and where such employee’s feet are exposed to electrical hazards.

Employees must use protective footwear when

- falling or rolling objects,

- objects piercing the sole,

- employee’s feet are exposed to electrical hazards.

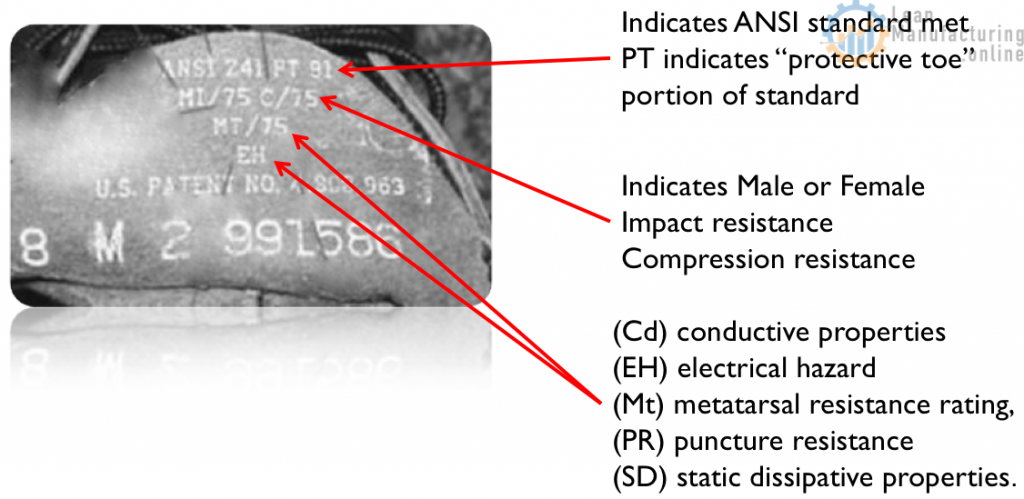

ANSI Markings – Footwear

Line #1: ANSI Z41 PT 99:

Identifies the ANSI standard. The letters PT indicate the protective toe section of the standard. The last two digits indicate the year of the standard with which the footwear meets compliance (1999).

Line #2: F I/75 C/75:

Identifies the applicable gender [M (Male) or F (Female)] for which the footwear is intended.

Impact resistance (I), the impact resistance rating (75, 50 or 30 foot-pounds),

Compression resistance (C) and the compression resistance rating (75, 50 or 30, which correlates to 2500 pounds, 1750 pounds, and 1000 pounds of compression, respectively).

Lines 3 & 4: Mt Cd EH PR & SD:

Lines 3 and 4 are used to reference additional sections in the standard. They are used to designate conductive (CD) properties, electrical hazard (EH), metatarsal (Mt) resistance rating, puncture resistance (PR) and static dissipative (SD) properties.

Employee Owned PPE

If an employee provides protective equipment, the employer shall be responsible for ensuring its adequacy, including proper maintenance and sanitation of such equipment.

Insulated Tools

The employee must use insulated tools or handling equipment when working near exposed conductors.

Employee Training

When PPE is required, the employer must cover the following areas:

- When PPE is necessary;

- What PPE is necessary;

- How to properly don and doff PPE;

- How to adjust and wear PPE;

- The limitations of the PPE and;

- The proper care, maintenance, useful life and disposal of the PPE.

Training Documentation

The employer must issue a written “training certificate,” which must include the following:

- the name of each employee trained;

- the date(s) of training, and;

- Identity of the subject covered.

This training is only for reference – always follow safety rules prescribed by your local legislation or H&S department.