Black Belt Training

Lean Six Sigma Tools Quick Reference

Lean Six Sigma is a methodology that combines the principles of Lean manufacturing with Six Sigma to improve the efficiency, quality, and effectiveness of business processes. It utilizes a set of tools and techniques to help organizations identify and eliminate waste, reduce variability, and increase customer satisfaction.

Read More »Data Collection Plan

Learning Objectives Prepare plans to collect output, process and input dataConstruct forms and test data collection proceduresRefine data collection Implement data collection plan Activities Value Stream Map for Deeper Understanding and FocusIdentify Key Input, Process and Output MetricsDevelop Operational DefinitionsDevelop Data CollectionPlan Validate Measurement SystemCollect Baseline DataDetermine Process CapabilityComplete Measure…

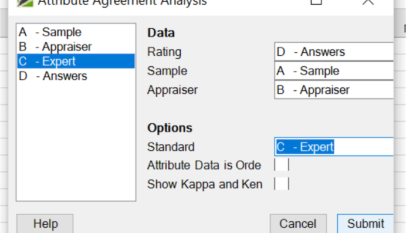

Read More »Attribute Agreement Analysis

Significance and Basic Definitions Every time someone makes a decision, it is critical that the decision-maker select the same choice again and that others reach the same conclusion. Attribute agreement analysis measures whether or not several people making a judgment or assessment of the same item would have a high…

Read More »Six Sigma

The sigma value is the relationship between the actual number of failures and the different possible ways that the product or service can fail.

Read More »